Coking waste-gas desulfurization process optimized control method

A control method and process optimization technology, applied in chemical variable control, chemical instruments and methods, ratio control, etc., can solve problems such as excessive range, waste of raw materials, overshoot and lag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

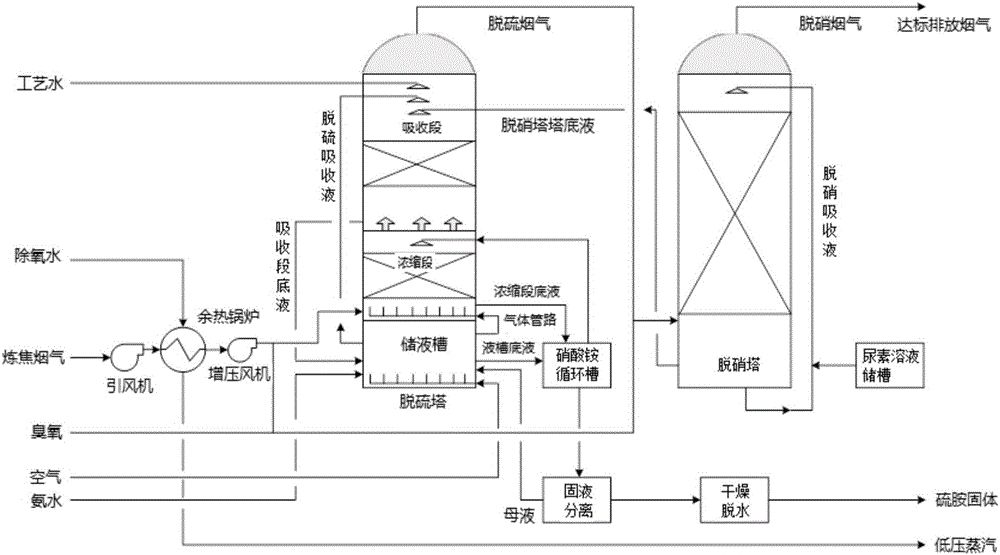

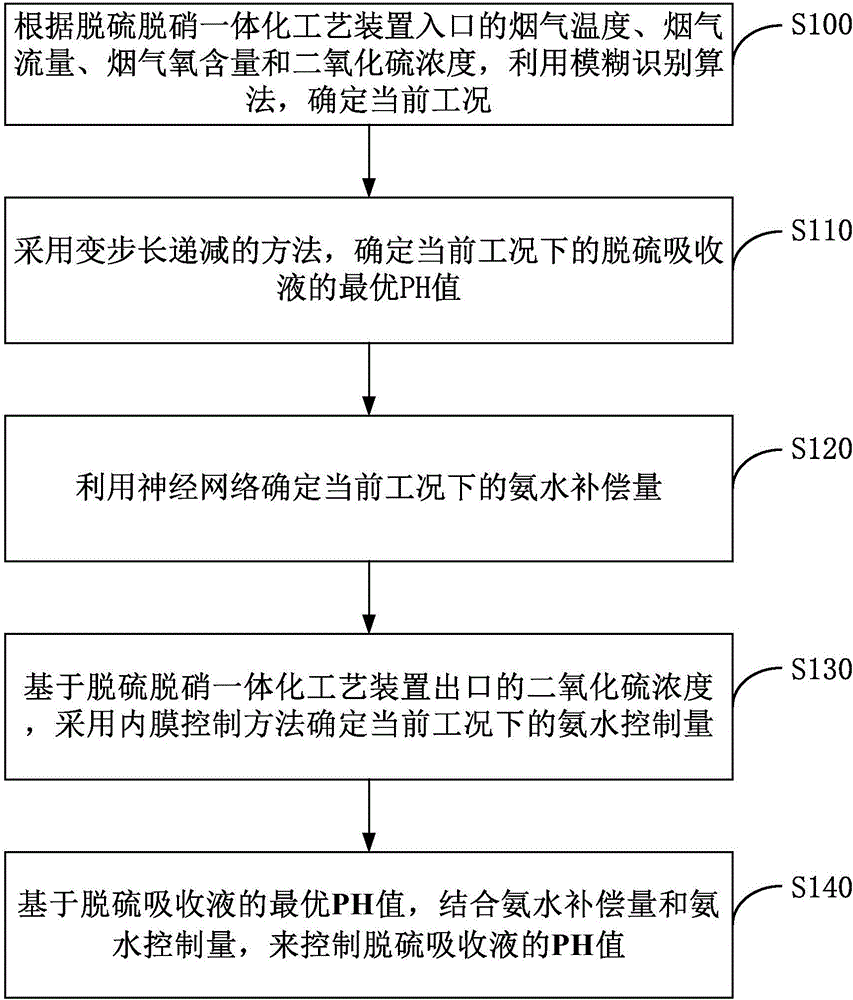

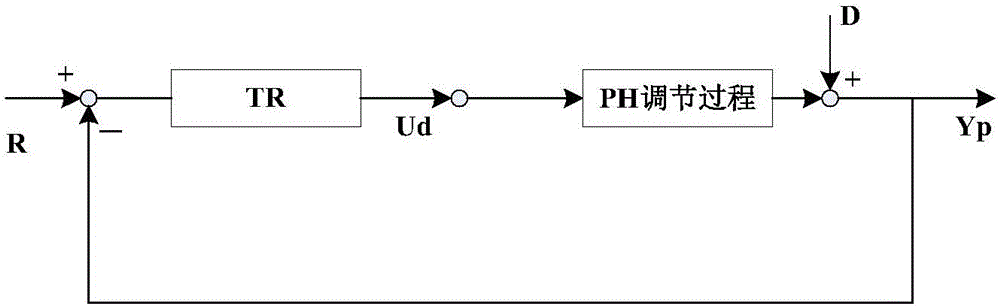

[0047] The basic idea of the embodiment of the present invention is: take the pH value of the desulfurization absorption liquid as the controlled variable, the flow rate of the ammonia solution as the control variable, adopt the internal model control structure with feed-forward compensation, and at the same time, control the desulfurization through the corresponding optimization strategy. The PH value of the absorption liquid, to find the optimal PH value under the current working conditions, so as to ensure that the desulfurization and denitrification integrated process device is in the most economical and environmentally friendly condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com