Clay desulfurizer as well as preparation method and application thereof

A desulfurization agent and clay technology, applied in the field of clay desulfurization agent and its preparation, can solve the secondary pollution of waste adsorbents and other problems, and achieve the effects of no secondary pollution, stable performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

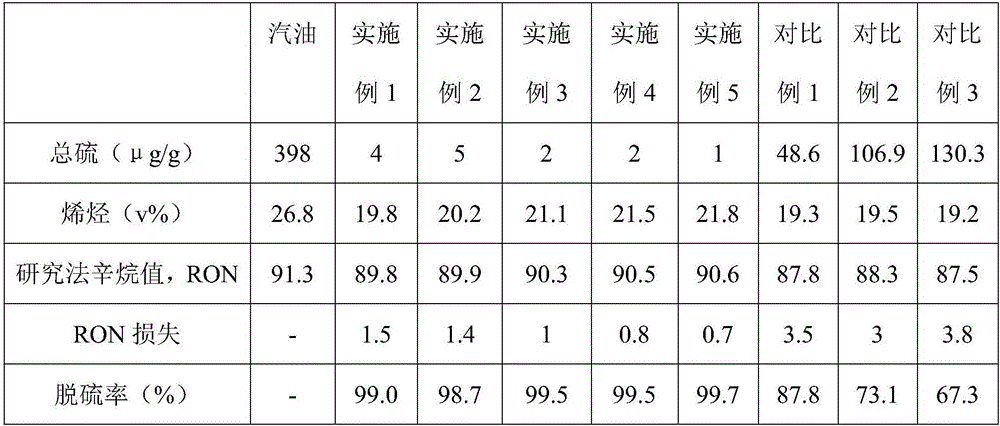

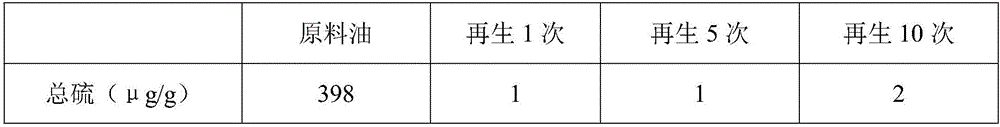

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a clay desulfurizer is composed of the following raw materials in parts by weight: 28 parts of clay, 1 part of pectin, 3 parts of perillaldehyde, and 11 parts of acetic acid.

[0018] Acetic acid solution is prepared by mixing acetic acid with 6.8 times its mass of ethanol with a volume concentration of 65%. Mix and grind the clay and pectin for 1.5h, then add acetic acid solution, raise the temperature to 69°C and seal and stir at this temperature for 1.9h, then raise the temperature to 83°C and add perillaldehyde dropwise, after the dropwise addition is completed, at this temperature Ultrasonic treatment for 22 minutes, the ultrasonic power is 1000W, and then stirred at a temperature of 99 ° C until dry, and then calcined in a muffle furnace at 440 ° C for 4.3 hours to obtain the desulfurizer.

Embodiment 2

[0020] In the embodiment of the present invention, a clay desulfurizer is composed of the following raw materials in parts by weight: 36 parts of clay, 5 parts of pectin, 7 parts of perillaldehyde, and 19 parts of acetic acid.

[0021] Mix acetic acid with 6.8 times its mass of 65% ethanol to prepare an acetic acid solution. Mix and grind clay and pectin for 1.6h, then add acetic acid solution, raise the temperature to 69°C and seal and stir at this temperature for 1.9h, then raise the temperature to 83°C and add perillaldehyde dropwise. Ultrasonic treatment for 22 minutes, the ultrasonic power is 1000W, and then stirred at a temperature of 101 ° C until dry, and then calcined in a muffle furnace at 440 ° C for 4.3 hours to obtain the desulfurization agent.

Embodiment 3

[0023] In the embodiment of the present invention, a clay desulfurizer is composed of the following raw materials in parts by weight: 30 parts of clay, 2 parts of pectin, 4 parts of perillaldehyde, and 13 parts of acetic acid.

[0024] Mix acetic acid with 6.8 times its mass of 65% ethanol to prepare an acetic acid solution. Mix and grind clay and pectin for 1.55 hours, then add acetic acid solution, raise the temperature to 69°C and seal and stir at this temperature for 1.9 hours, then raise the temperature to 83°C and add perillaldehyde dropwise, after the dropwise addition is completed, under this temperature Ultrasonic treatment for 22 minutes, the ultrasonic power is 1000W, and then stirred at a temperature of 100 ° C until dry, and then calcined in a muffle furnace at 440 ° C for 4.3 hours to obtain the desulfurization agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com