Modified extruded catalyst used for alkylation reaction, and preparation method and application thereof

An alkylation reaction and catalyst technology, which is applied in the field of modified catalysts, can solve the problems of reducing the activity of molecular sieves and lack of practicability, and achieve the effects of good shape selection, reduced template dosage, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] According to one embodiment of the present invention, the shaped body comprises: a substance whose precursor is a binder and the alkylation reactive component, wherein the content of the substance whose precursor is a binder and the alkylation The content of the reactive components can be known in the art. For the present invention, the content of the precursor is preferably 10% by weight-50% by weight, and the content of the alkylation reactive component is 50% by weight. -90% by weight.

[0030] According to the present invention, the substance whose precursor is a binder refers to that it is used as a binder during the molding process, and after the final roasting to obtain a molded body, the binder is converted into an oxide, that is, the binder used in the present invention The precursor is the substance of the binder.

[0031] According to the present invention, the type of the substance whose precursor is the binder is well known in the art, for example, it may ...

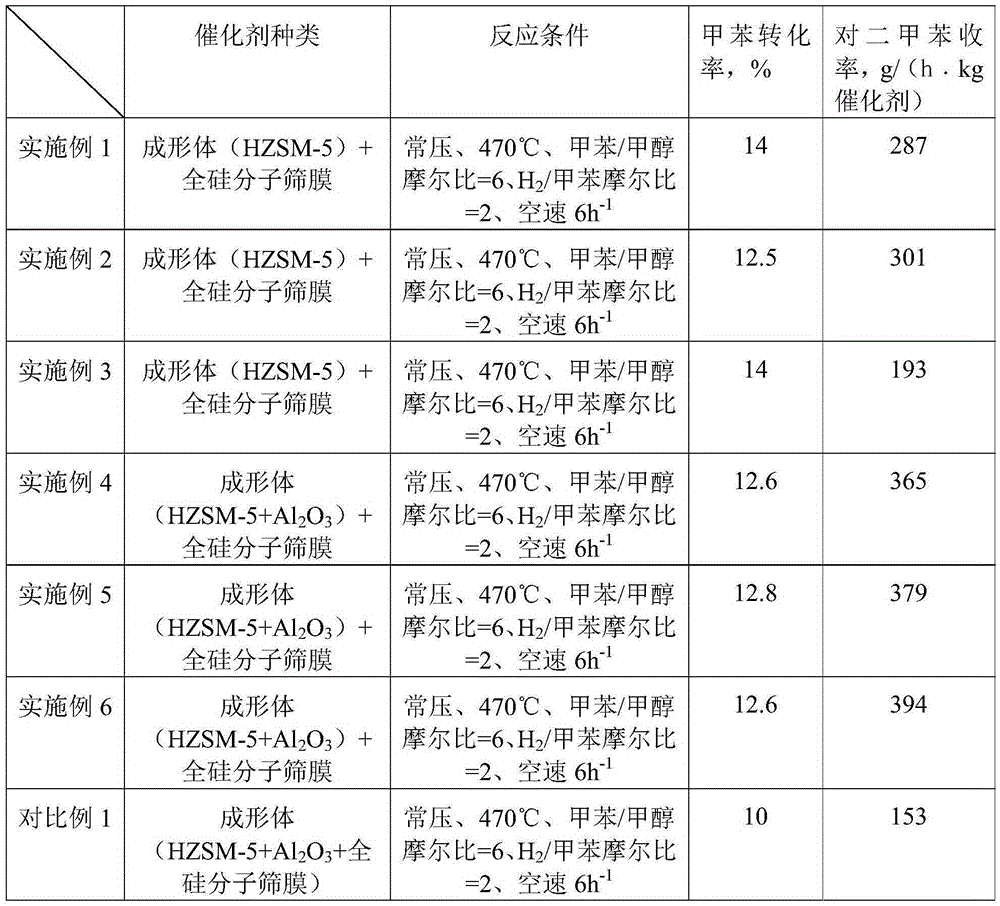

Embodiment 1

[0055] (1) Take the commercialized HZSM-5 (Si / Al (molar ratio)=60), press it to 30MPa in a tablet press, then crush and sieve into 20-40 mesh samples;

[0056] (2) 5 grams of molding samples in step (1) are mixed with 22 grams of tetraethyl orthosilicate, 21.6 grams of TPAOH solution (25wt% aqueous solution), 19.5 grams of ethanol and 100 grams of water, and 160 grams of water in a self-pressure crystallization kettle ℃ crystallization for 72 hours;

[0057] (3) Filter the crystallized sample in step (2), wash it with deionized water until neutral, and then dry it in an oven at 120°C for 2 hours;

[0058] (4) Place the sample obtained in step (3) in a muffle furnace, raise it from room temperature to 550°C at 2K / min in a flowing air atmosphere, and then bake at a constant temperature of 550°C for 5 hours and naturally cool to room temperature to obtain the finished product Catalyst (film thickness is 0.5μm);

[0059] (5) 1.2 grams of finished catalysts are heated at normal p...

Embodiment 2

[0061] (1) with step (1) in embodiment 1;

[0062] (2) 2.5 grams of molding samples in step (1) are mixed with 22 grams of tetraethyl orthosilicate, 21.6 grams of TPAOH solution (25wt% aqueous solution), 19.5 grams of ethanol and 100 grams of water. ℃ crystallization for 72 hours;

[0063] (3) with step (3) in embodiment 1;

[0064] (4) with step (4) in embodiment 1, obtain finished product catalyst (film thickness is 0.8 μ m);

[0065] (5) 1.2 grams of finished catalysts are heated at normal pressure, 470°C, toluene / methanol (mol / mol)=6, H 2 / toluene (mol / mol)=2, space velocity 6h -1 Under the condition of reaction, the conversion rate of toluene is 12.5%, and the p-xylene yield per kilogram of catalyst per hour is 301 grams.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com