Treatment method for microcystin in tap water

A microcystin and treatment method technology, which is applied in water/sewage treatment, special compound water treatment, oxidized water/sewage treatment, etc., can solve the problems of ozone oxidation degradation that no one has studied, and save reaction time and energy consumption , high processing efficiency, and the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

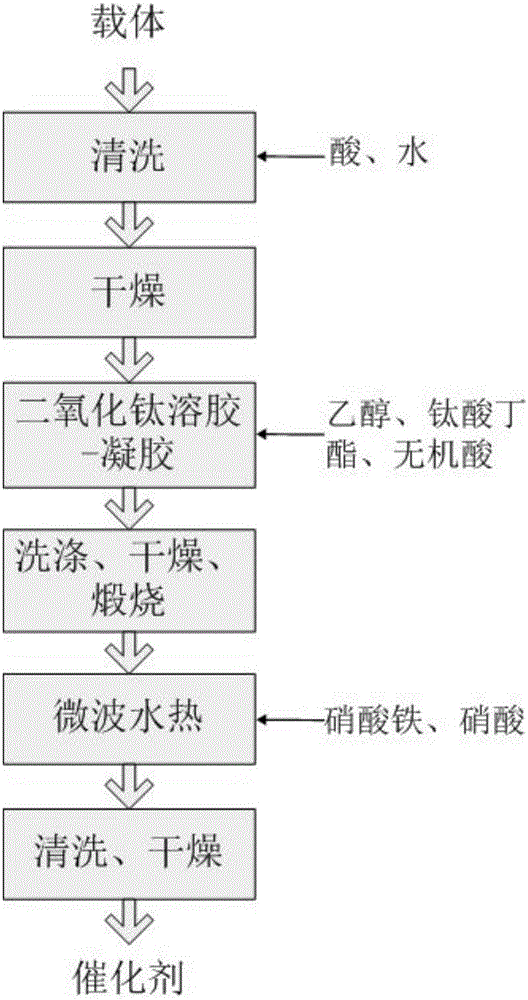

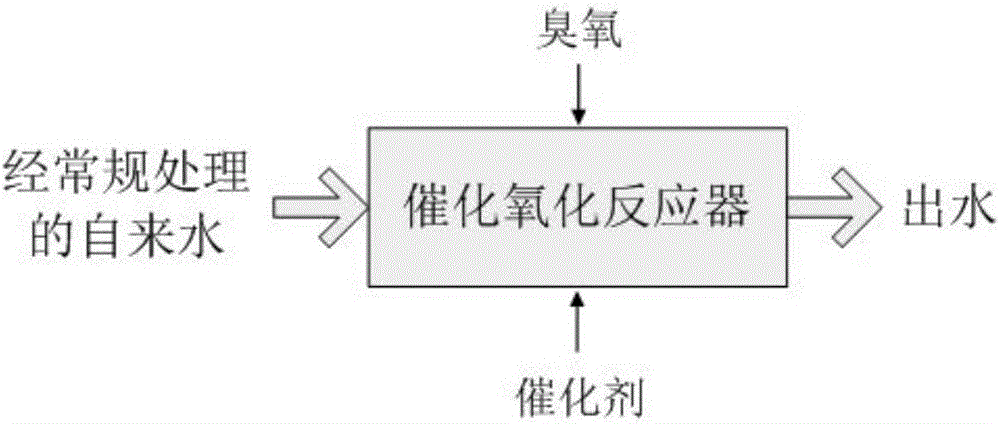

[0048] (1) Catalyst preparation: The activated carbon particles were washed with tap water and dried in a constant temperature drying oven at 105°C. 380 kg of cleaned activated carbon was immersed in 760 L of 3.5 mol / L hydrochloric acid solution for 24 hours, then washed with tap water until neutral, and dried at 105 ° C to obtain pretreated activated carbon.

[0049] After mixing ethanol and butyl titanate, add nitric acid solution dropwise, so that the volume ratio of the three reaches 1:10:1.5, and the pH reaches 2.5. Stir well and age to get TiO 2 Sol. Soak pretreated activated carbon in 1400L TiO 2 In the sol, after fully reacting for 12 hours, wash, dry at 105°C, and calcinate in a muffle furnace at 650°C for 4 hours to obtain activated carbon-supported TiO 2 catalyst.

[0050] Mix 3.8mM ferric nitrate solution with 11.5mM nitric acid solution, adjust the pH of the mixture to 2.2, and add the above activated carbon-loaded TiO 2 The catalyst was immersed in 1000L mix...

Embodiment 2

[0053] (1) Catalyst preparation: the honeycomb ceramic particles were washed with tap water, and dried in a constant temperature drying oven at 105°C. 200 kg of cleaned honeycomb ceramics were immersed in 200 L of 3.0 mol / L hydrochloric acid solution for 24 hours, then washed with tap water until neutral, and dried at 105 ° C to obtain pretreated honeycomb ceramics.

[0054] After mixing ethanol and butyl titanate, add hydrochloric acid solution drop by drop, so that the volume ratio of the three reaches 1:6:0.8, and the pH reaches 2.5. Stir well and age to get TiO 2 Sol. Soak the pretreated honeycomb ceramics in 1000L TiO 2 In the sol, after fully reacting for 14 hours, wash, dry at 105°C, and calcinate in a muffle furnace at 600°C for 4 hours to obtain honeycomb ceramic-supported TiO 2 catalyst.

[0055] Mix 1.5mM ferric nitrate solution with 10.0mM nitric acid solution, adjust the pH of the mixture to 2.0, and mix the above-mentioned honeycomb ceramic-supported TiO 2 T...

Embodiment 3

[0058] (1) Catalyst preparation: the ceramsite was washed with tap water, and dried in a constant temperature drying oven at 105°C. Immerse 100kg of cleaned ceramsite in 100L of 1.0mol / L hydrochloric acid solution for 24h, then wash with tap water until neutral, and dry at 105°C to obtain pretreated ceramsite.

[0059] After mixing ethanol and butyl titanate, add hydrochloric acid solution dropwise, so that the volume ratio of the three reaches 1:4:0.5, and the pH reaches 1.5. Stir well and age to get TiO 2 Sol. Soak the pretreated ceramsite in 620L TiO 2 In the sol, after fully reacting for 18 hours, wash, dry at 105°C, and calcinate at 500°C for 2 hours in a muffle furnace to obtain ceramsite-supported TiO 2 catalyst.

[0060] Mix 1.2mM ferric nitrate solution with 7.5mM nitric acid solution, adjust the pH of the mixture to 1.5, and mix the above ceramsite-loaded TiO 2 The catalyst was immersed in 150L mixed solution, subjected to microwave hydrothermal treatment for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com