Treating and recycling device for wastewater from iron and steel enterprises and technique

A wastewater treatment and enterprise technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve problems such as difficulty, high treatment cost, low efficiency, etc., to reduce treatment costs and unique circular economy advantages , to achieve efficient and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

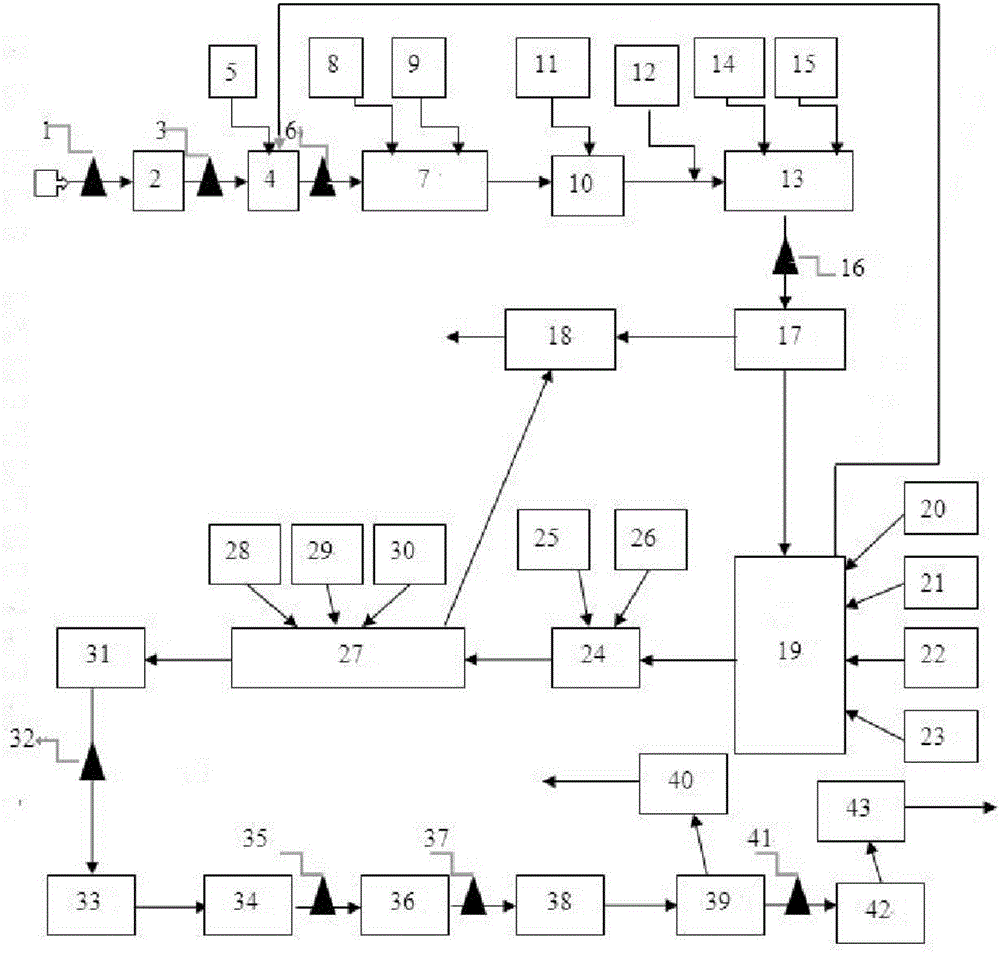

[0065] A device for treatment and reuse of wastewater from iron and steel enterprises, including grilles, regulating tanks, flocculation and water distribution structures, high-density sedimentation tanks, mud storage tanks, V-type filters, Fenton oxidation reaction tanks, reaction sedimentation tanks, and multi-media Filter device, CMF device, activated carbon filter device, reverse osmosis device and reverse osmosis product water pool; among them:

[0066] The inlet end of the grille is connected to the waste water outlet through a water inlet pump, and the drain end of the grille is connected to the water inlet of the regulating tank through a first pressurizing pump, and a submersible agitator is arranged in the regulating tank, The outlet of the regulating tank is connected to the water inlet of the flocculation and water distribution structure through a submersible lift pump. The top of the flocculation and water distribution structure is respectively provided with a dosing ...

Embodiment 2

[0089] A device for treatment and reuse of wastewater from iron and steel enterprises, including grilles, regulating tanks, flocculation and water distribution structures, high-density sedimentation tanks, mud storage tanks, V-type filters, Fenton oxidation reaction tanks, reaction sedimentation tanks, and multi-media Filter device, CMF device, activated carbon filter device, reverse osmosis device and reverse osmosis product water pool; among them:

[0090] The inlet end of the grille is connected to the waste water outlet through a water inlet pump, and the drain end of the grille is connected to the water inlet of the regulating tank through a first pressurizing pump, and a submersible agitator is arranged in the regulating tank, The outlet of the regulating tank is connected to the water inlet of the flocculation and water distribution structure through a submersible lift pump. The top of the flocculation and water distribution structure is respectively provided with a dosing ...

Embodiment 3

[0110] A device for treatment and reuse of wastewater from iron and steel enterprises, including grilles, regulating tanks, flocculation and water distribution structures, high-density sedimentation tanks, mud storage tanks, V-type filters, Fenton oxidation reaction tanks, reaction sedimentation tanks, and multi-media Filter device, CMF device, activated carbon filter device, reverse osmosis device and reverse osmosis product water pool; among them:

[0111] The inlet end of the grille is connected to the waste water outlet through a water inlet pump, and the drain end of the grille is connected to the water inlet of the regulating tank through a first pressurizing pump, and a submersible agitator is arranged in the regulating tank, The outlet of the regulating tank is connected to the water inlet of the flocculation and water distribution structure through a submersible lift pump. The top of the flocculation and water distribution structure is respectively provided with a dosing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com