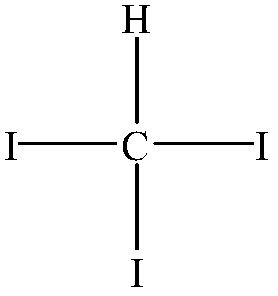

A kind of purification method of triiodomethane

A triiodomethane and purification method technology, which is applied in the field of triiodomethane purification, can solve the problems of low content of finished products, many impurities, and unsatisfactory products, and achieve the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

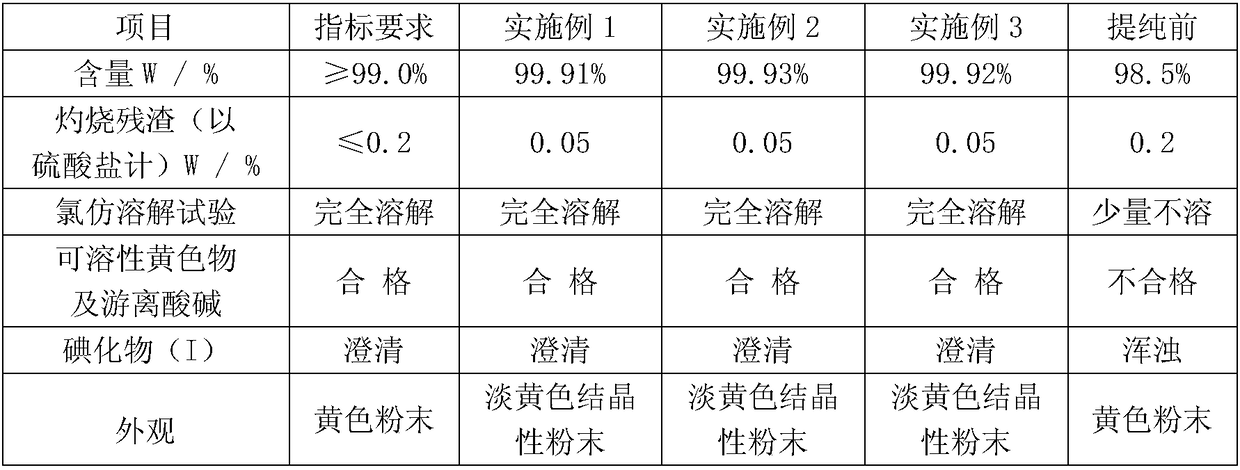

[0027] Add 100ml of acetone into 100ml of ethanol, stir and mix to obtain a compound solvent. Add 40g of triiodomethane into the compound solvent, stir until all the solids are dissolved, filter, concentrate under reduced pressure in a water bath at 34°C with a vacuum of -0.06Mpa, and concentrate until no liquid drips out. Pour the concentrated solution into a 500ml beaker, place it in an ice-water bath, the temperature of the ice-water bath is 5-7°C, crystallize until a large amount of crystals are precipitated, centrifuge to obtain a wet material, dry at 35°C for 1 hour, and vacuum degree is -0.09Mpa to obtain three 35g of methyl iodide pure product, the finished product purity is 99.91%, the specific test results are shown in Table 1.

Embodiment 2

[0029] Add 50ml of diethyl ether into 150ml of petroleum ether with a boiling range of 60-90°C, stir and mix to obtain a compound solvent. Add 25g of triiodomethane into the compound solvent, stir until all the solids are dissolved, filter, concentrate under reduced pressure in a water bath at 25°C, the vacuum degree of reduced pressure is -0.08Mpa, and concentrate until no liquid drips out. Pour the concentrated solution into a 500ml beaker, place it in an ice-water bath, the temperature of the ice-water bath is 4-6°C, crystallize until a large amount of crystals are precipitated, centrifuge to obtain the wet material, dry at 30°C for 1.5h, and the vacuum degree is -0.1Mpa to obtain Triiodomethane pure product 21g, the finished product purity is 99.93%, and concrete detection result is shown in Table 1.

Embodiment 3

[0031] Add 100ml of acetone to 200ml of water, stir and mix to obtain a compound solvent. Add 75g of triiodomethane into the compound solvent, stir until all the solids are dissolved, filter, concentrate under reduced pressure in a water bath at 20°C, the vacuum degree of reduced pressure is -0.1Mpa, and concentrate until no liquid drips out. Pour the concentrated solution into a 500ml beaker, place it in an ice-water bath, the temperature of the ice-water bath is 1-3°C, crystallize until a large amount of crystals are precipitated, centrifuge to obtain a wet material, dry at 40°C for 1.5h, and the vacuum degree is -0.08Mpa to obtain Triiodomethane pure product 68g, finished product purity is 99.92%, concrete test result is shown in Table 1.

[0032] Table 1 Comparison of test results

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com