A kind of phosphogypsum base material imitation jade decorative board and preparation method thereof

A technology for phosphogypsum and decorative boards, which is applied in the field of phosphogypsum base material imitation jade decorative boards and its preparation, can solve the problems such as the difficulty in solving the emission of phosphogypsum, and achieve the effects of promoting solidification performance, enhancing strength, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

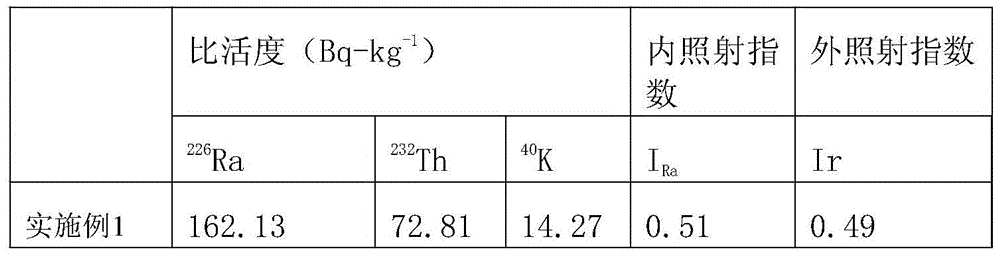

Embodiment 1

[0031] A phosphogypsum base material imitation jade decorative plate, its raw material components are 30kg of phosphogypsum, 0.1kg of quicklime, 5kg of fly ash, 2kg of ceramic fiber, and 20kg of imitation jade paint.

[0032] The imitation jade paint is composed of imitation jade primer, imitation jade top coat and varnish, which are stored separately. Among them, the imitation jade primer accounts for one-third of the imitation jade paint, the varnish is 0.2kg, and the rest is the imitation jade top coat.

[0033] The content of sodium ions in phosphogypsum is 0.1%.

[0034] The content of soluble phosphorus in phosphogypsum is 10%.

[0035] The content of sodium ion in fly ash is 0.1%.

[0036] The sulfur content in fly ash is 2%.

[0037] The length of the ceramic fiber is 0.1 mm.

[0038] The preparation method of the phosphogypsum substrate imitation jade decorative board comprises the following steps:

[0039](1) Raw material processing: put phosphogypsum in the mixi...

Embodiment 2

[0047] A phosphogypsum base material imitation jade decorative plate, its raw material components are 50kg of phosphogypsum, 1kg of quicklime, 9kg of fly ash, 3kg of ceramic fiber, and 30kg of imitation jade paint.

[0048] The imitation jade paint is composed of imitation jade primer, imitation jade top coat and varnish, which are stored separately. Among them, the imitation jade primer accounts for one-third of the imitation jade paint, the varnish is 2.7kg, and the rest is the imitation jade top coat.

[0049] The content of sodium ion in phosphogypsum is 0.01%.

[0050] The content of soluble phosphorus in phosphogypsum is 9%.

[0051] The content of sodium ion in fly ash is 0.09%.

[0052] The sulfur content in fly ash is 1%.

[0053] The length of the ceramic fiber is 0.7mm.

[0054] The preparation method of the phosphogypsum substrate imitation jade decorative board comprises the following steps:

[0055] (1) Raw material processing: put phosphogypsum in the mixing...

Embodiment 3

[0063] A phosphogypsum base material imitation jade decorative plate, its raw material components are 40kg of phosphogypsum, 0.7kg of quicklime, 7kg of fly ash, 2.5kg of ceramic fiber, and 25kg of imitation jade paint.

[0064] The imitation jade paint is composed of imitation jade primer, imitation jade top coat and varnish, which are stored separately. Among them, the imitation jade primer accounts for one-third of the imitation jade paint, 1.25kg of varnish, and the rest is imitation jade top coat.

[0065] The content of sodium ion in phosphogypsum is ≤0.07%.

[0066] The content of soluble phosphorus in phosphogypsum is 8%.

[0067] The content of sodium ion in fly ash is 0.05%.

[0068] The sulfur content in fly ash is 0.1%.

[0069] The length of the ceramic fiber is 0.5 mm.

[0070] The preparation method of the phosphogypsum substrate imitation jade decorative board comprises the following steps:

[0071] (1) Raw material processing: put phosphogypsum in the mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com