Curdlan and extraction process thereof

An extraction process and soluble technology, applied in the field of keratin and its extraction process, can solve the problems of great influence on product quality, destruction of molecular structure, large alkali-containing wastewater, etc., and achieve high product quality, fast treatment speed, and reduced Effects of Soluble Impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

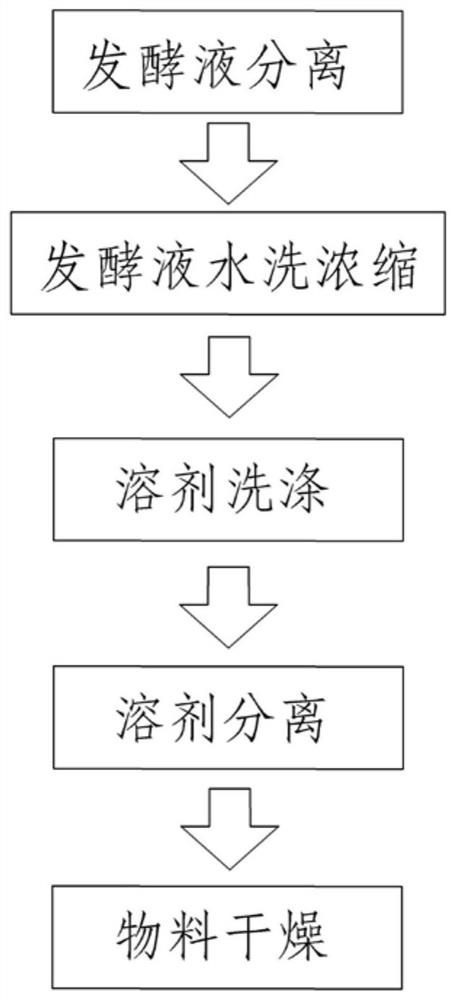

[0042] like figure 1 As shown, the present embodiment provides a kind of extraction process of curdlan gum, comprising the steps:

[0043] S1, Separation of fermentation broth: first, use a centrifuge with a separation factor of 5100 to conduct preliminary separation and concentration of the fermentation broth, initially remove soluble impurities in the fermentation broth, and obtain a preliminary concentrated fermentation broth;

[0044] S2, washing and concentrating the fermented broth: add water with a conductivity 45 μs / cm three times the volume of the original fermented broth to the separated preliminary concentrated fermented broth, use a centrifuge to perform secondary separation and concentration on the diluted fermented broth, and concentrate until fermentation The solids in the liquid account for the fermented liquid, stop at 15%, further remove the soluble impurities in the fermented liquid, and obtain the water-washed concentrated fermented liquid;

[0045] S3, so...

Embodiment 2

[0049] like figure 1 As shown, the present embodiment provides a kind of extraction process of curdlan gum, comprising the steps:

[0050] S1, Separation of fermentation broth: first, use a centrifuge with a separation factor of 5500 to conduct preliminary separation and concentration of the fermentation broth, and initially remove soluble impurities in the fermentation broth to obtain a preliminary concentrated fermentation broth;

[0051] S2, washing and concentrating the fermented broth: add water with a conductivity 50 μs / cm three times the volume of the original fermented broth to the separated preliminary concentrated fermented broth, use a centrifuge to carry out secondary separation and concentration on the diluted fermented broth, and concentrate until fermented The solids in the liquid account for 10% of the fermentation liquid, and the soluble impurities in the fermentation liquid are further removed to obtain the water-washed concentrated fermentation liquid;

[0...

Embodiment 3

[0056] like figure 1 As shown, the present embodiment provides a kind of extraction process of curdlan gum, comprising the steps:

[0057] S1, separation of fermentation broth: first, use a centrifuge with a separation factor of 5000 to carry out preliminary separation and concentration of the fermentation broth, initially remove soluble impurities in the fermentation broth, and obtain a preliminary concentrated fermentation broth;

[0058] S2, washing and concentrating the fermented broth: add water with a conductivity 48 μs / cm 4 times the volume of the original fermented broth to the separated preliminary concentrated fermented broth, use a centrifuge to carry out secondary separation and concentration on the diluted fermented broth, and concentrate until fermented The solids in the liquid account for the fermented liquid, stop at 5%, further remove the soluble impurities in the fermented liquid, and obtain the water-washed concentrated fermented liquid;

[0059] S3, solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com