Preparation method for microcrystalline cellulose capable of increasing drug dissolution rate

A microcrystalline cellulose and dissolution technology, applied in the pharmaceutical field, can solve the problems of partial bottom line, fluctuation of drug dissolution, unqualified, etc., and achieve the effect of eliminating influence, simple production operation and less waste residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

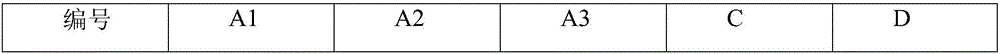

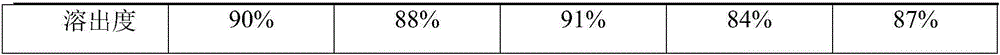

Examples

Embodiment 1

[0022] 1. Put 300 parts of water in the reaction kettle, add 9.5 parts of hydrochloric acid, detect the acid concentration as 0.30mol / L, turn on the steam and heat to 72°C, close the intake valve, start stirring, and put 100 parts of refined cotton cut into small slices Put it into the reaction kettle, after feeding, open the steam valve to raise the temperature to 100°C, and react for 42 minutes.

[0023] 2. Dilute and stratify: Put 560 parts of water in the storage tank, put the material after the above reaction into the storage tank, stir well and let it stand for 2 hours to make the material stratify.

[0024] 3. Centrifugal washing: extract the upper 1 / 2 slurry of the material part after standing still and enter it into centrifugal washing. After the slurry is dried, wash it with reverse osmosis water until the pH value of the water flowing out of the centrifuge outlet is 7, and stop washing. Continue to centrifuge and dry to obtain material A, and the remaining lower lay...

Embodiment 2

[0028] 1. Put 300 parts of water in the reaction kettle, add 10 parts of hydrochloric acid, check the acid concentration to be 0.31mol / L, turn on steam and heat to 70°C, close the intake valve, start stirring, and put 100 parts of refined cotton cut into small slices Put it into the reaction kettle, after feeding, open the steam valve to raise the temperature to 100°C, and react for 40 minutes.

[0029] 2. Dilution and stratification: Put 570 parts of water in the storage tank, put the materials that have completed the above reaction into the storage tank, stir them and let stand for 4 hours to make the materials layered.

[0030] 3. Centrifugal washing: extract the upper 3 / 4 slurry of the material part after standing still and enter it into centrifugal washing. After the slurry is dried, wash it with reverse osmosis water until the pH value of the water flowing out of the centrifuge outlet is 7, and stop washing. Continue to centrifuge and dry to obtain material A, and the re...

Embodiment 3

[0034] 1. Put 300 parts of water in the reaction kettle, add 11.2 parts of hydrochloric acid, check the acid concentration to be 0.35mol / L, turn on steam and heat to 69°C, close the intake valve, start stirring, and put 100 parts of refined cotton cut into small slices Put it into the reaction kettle, after feeding, open the steam valve to raise the temperature to 100°C, and react for 37 minutes.

[0035] 2. Dilution and stratification: put 580 parts of water in the storage tank, put the material after the above reaction into the storage tank, stir well and let it stand for 3 hours to make the material stratify.

[0036] 3. Centrifugal washing: extract the upper 1 / 4 slurry of the material part after standing to enter the centrifugal washing, after the slurry is dried, wash with reverse osmosis water until the pH value of the water flowing out of the centrifuge outlet is 7, stop washing, Continue to centrifuge and dry to obtain material A, and the remaining lower layer material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com