High-performance full-MDI polyurethane mixed component for automobile seats, and preparation method thereof

A polyurethane composite material, a technology for car seats, applied in the field of polymer materials, can solve the problems of reducing the service life of car seats, sitting comfort, poor tear strength, tensile strength, poor resilience, etc. The method is simple and easy to implement, with good resilience and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

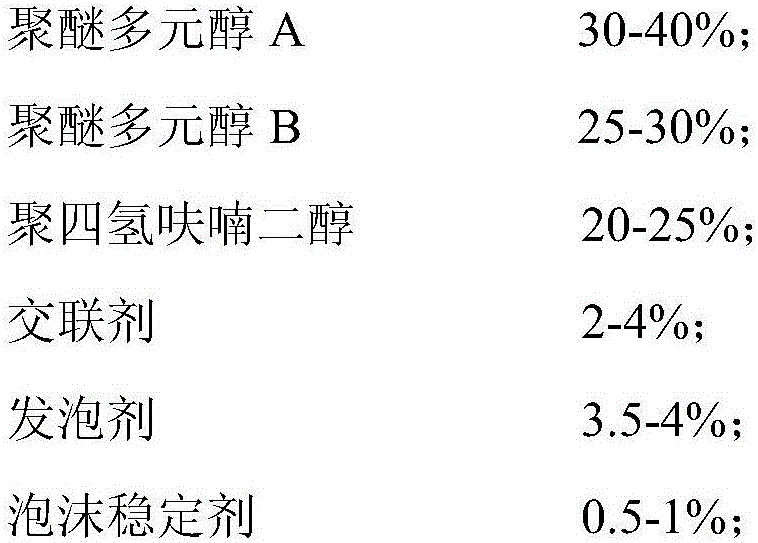

[0040] Component A is made of raw materials in the following weight percentages:

[0041]

[0042]

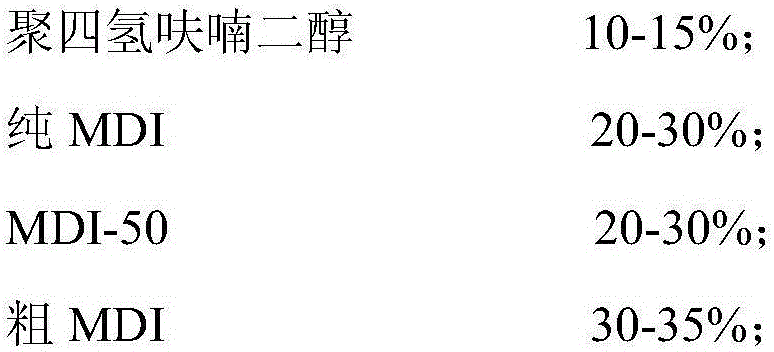

[0043] Component B is made of raw materials in the following weight percentages:

[0044]

[0045] Its preparation method is as follows:

[0046] Component A: Weigh 35kg of MC28-02, 30kg of GPOPH45Y and 20kg of PTMG1500 into the reactor for stirring, then add 2kg of YNW-303A and 4kg of H 2 O, 0.5kg of EPK-127, 3kg of GK-350D, 0.5kg of NE300, at room temperature, the rotation speed is 55 rpm, stirred for 1 hour, and the product of component A is obtained;

[0047] Component B: Take 10kg of PTMG2000 and place it in a reactor, raise the temperature to 115°C and dehydrate under vacuum (-0.09MPa) for 1.8 hours, then lower the temperature to 45°C, add 25kg of 44C and 30kg of 0129M, and slowly raise the temperature to 78°C, Insulate and react for 1.5 hours, then add 35kg of PM200, stir for 0.5 hours, take a sample and test, the mass content of -NCO reaches 29.2±0.2%, cool d...

Embodiment 2

[0051] Component A is made of raw materials in the following weight percentages:

[0052]

[0053] Component B is made of raw materials in the following weight percentages:

[0054]

[0055] Its preparation method is as follows:

[0056] Component A: Weigh 40kg of MC28-02, 25kg of GPOPH45Y and 20.5kg of PTMG1500 into the reactor for stirring, then add 4kg of YNW-303A and 3.5kg of H 2 O, 1kg of AK7713, 5kg of Yukol8331, 1kg of DPA, at room temperature, the rotation speed is 50 rpm, and stirred for 1.5 hours to obtain the product of component A;

[0057]Component B: Take 15kg of PTMG2000 and place it in a reaction kettle, heat up to 110°C and dehydrate under vacuum (-0.09MPa) for 1.5 hours, then cool down to 45°C, add 30kg of 44C and 25kg of 0129M, slowly heat up to 75°C, and keep warm React for 1.5 hours, then add 30kg of PM200, stir for 1 hour, take a sample and test, the mass content of -NCO reaches 27.5±0.2%, cool down to 42°C, discharge, and seal for storage.

[00...

Embodiment 3

[0061] Component A is made of raw materials in the following weight percentages:

[0062]

[0063] Component B is made of raw materials in the following weight percentages:

[0064]

[0065] Its preparation method is as follows:

[0066] Component A: Weigh 30kg of MC28-02, 30kg of GPOPH45Y and 25kg of PTMG1500 into the reactor for stirring, then add 4kg of YNW-303A and 4kg of H 2 O, 1kg of AK7713, 5kg of Yukol 8331, 1kg of DPA, at room temperature, the rotating speed is 60 rpm, and stirred for 1 hour to obtain the product of component A;

[0067] Component B: Take 10kg of PTMG2000 and place it in a reactor, raise the temperature to 110°C and dehydrate under vacuum (-0.09MPa) for 2 hours, then cool down to 50°C, add 30kg of 44C and 30kg of 0129M, slowly raise the temperature to 80°C, and keep warm for reaction After 1.5 hours, add 30kg of PM200, stir for 1.2 hours, take a sample and test, the mass content of -NCO reaches 29.4±0.2%, cool down to 42°C and discharge, seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com