PC/ABS composition with low smoke density and preparation method of PC/ABS composition

A technology of smoke density and composition, which is applied in the field of low smoke density PC/ABS composition and its preparation, can solve the problem that the degree of smoke suppression is not enough to meet the requirements of material safety performance, and achieve the suppression of smoke generation, uniform appearance, No harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

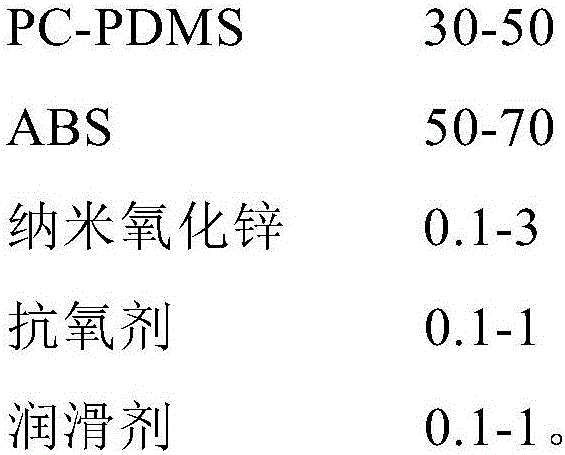

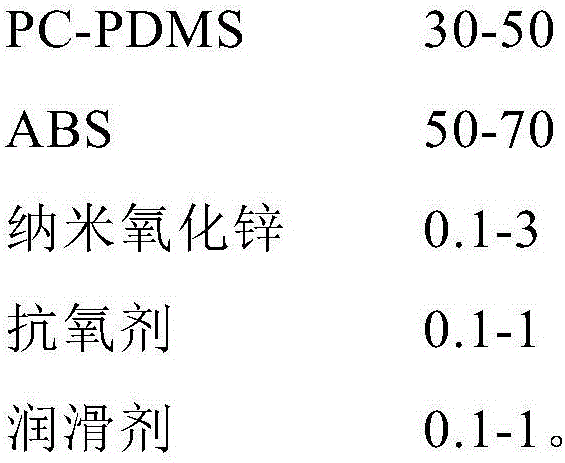

[0030] (1) Take by weight 30 parts of PC-PDMS, 70 parts of ABS, 0.1 part of nano zinc oxide prepared by ultrasonic method, 0.1 part of antioxidant, 0.1 part of lubricant;

[0031] (2) Feed the raw materials from the feeding port, melt and extrude at 200-260°C, the screw extruder speed is 500rpm, the pressure is 3MPa, after melt extrusion, granulation to obtain the product, the diameter of the extruder screw It is 35mm and the aspect ratio is 32.

Embodiment 2

[0033] (1) Take by weight 50 parts of PC-PDMS, 50 parts of ABS, 3 parts of nano zinc oxide prepared by ultrasonic method, 1 part of antioxidant, 0.5 part of lubricant;

[0034] (2) Feed the raw materials from the feeding port, melt and extrude at 200-260°C, the screw extruder speed is 450rpm, the pressure is 3.5MPa, after melt extrusion, granulation to obtain the product, the extruder screw The diameter is 35mm and the aspect ratio is 32.

Embodiment 3

[0036] (1) take by weight 40 parts of PC-PDMS, 60 parts of ABS, 0.7 parts of nano-zinc oxide prepared by ultrasonic method, 0.5 parts of antioxidant, 0.8 parts of lubricant;

[0037] (2) Feed the raw materials from the feeding port, melt and extrude at 200-260°C, the screw extruder speed is 550rpm, the pressure is 2.5MPa, after melt extrusion, granulation to obtain the product, the extruder screw The diameter is 35mm and the aspect ratio is 32.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com