Electrolyte for lithium metal battery and preparation method and application thereof

A lithium metal battery and electrolyte technology, applied in electrolytes, secondary batteries, secondary battery repair/maintenance, etc., can solve problems such as combustion of carbonate-based electrolytes, improve cycle stability, suppress parasitic reactions, The effect of preventing burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing an electrolyte for a lithium metal battery of the present invention comprises the following steps: (1) purifying and removing impurities and water from the above-mentioned organic solvent; (2) combining the electrolyte lithium salt with the step (1) Mixture of organic solvents.

[0036] Preferably, purification and removal of impurities and water removal are preferably carried out by any one or more of molecular sieves, activated carbon, calcium hydride, lithium hydride, anhydrous calcium oxide, calcium chloride, phosphorus pentoxide, alkali metals or alkaline earth metals . More preferably, described molecular sieve can adopt type, type or type, preferably type or type.

[0037] Specifically, the steps of purifying and removing impurities and removing water from organic solvents are as follows: Purifying and removing impurities and removing water are preferably carried out through molecular sieves, activated carbon, calcium hydride, li...

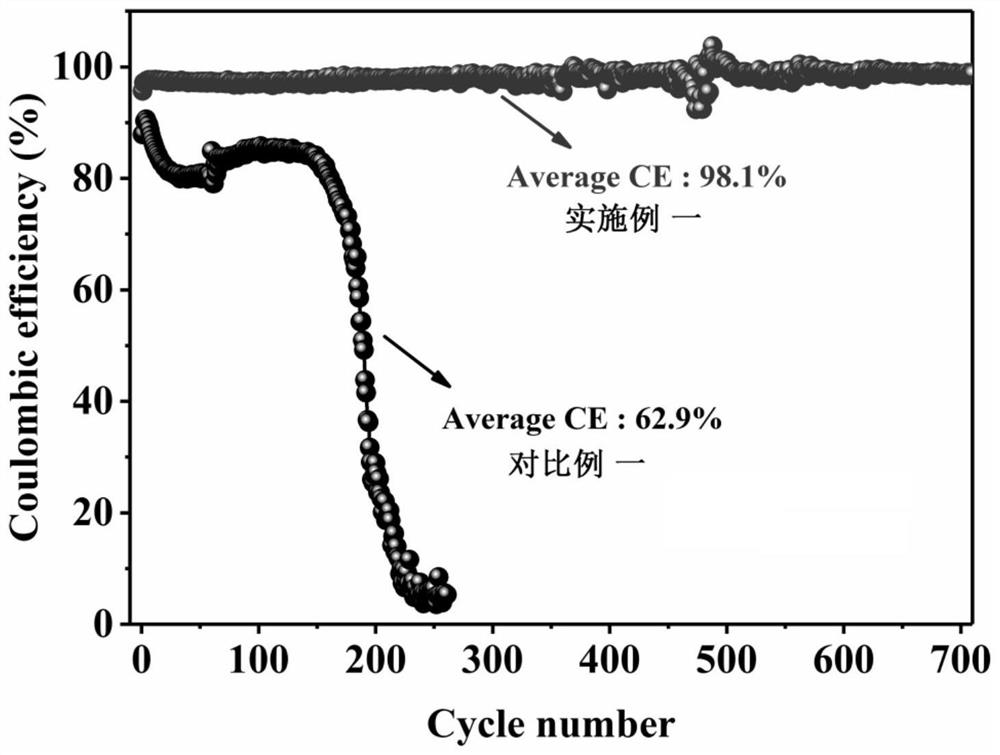

Embodiment 1

[0045] A kind of electrolyte solution for lithium metal battery of the present embodiment, its preparation method comprises:

[0046] Vinyl ethylene carbonate (VEC) and bis(2,2,2-trifluoroethyl) carbonate (TFEC) are mixed at a volume ratio of VEC:TFEC=3:7, and purified by molecular sieves, calcium hydride, and lithium hydride Miscellaneous, remove water (moisture <10ppm), get mixed solvent;

[0047] At room temperature, the electrolyte lithium salt LiPF 6 Dissolve in the above mixed solvent so that the final concentration of the electrolyte lithium salt is 1.0 mol / L, stir evenly, and leave to stand to obtain a novel electrolyte solution for lithium metal batteries.

[0048] Among them, the chemical structural formulas of VEC and TFFEC are as follows:

[0049]

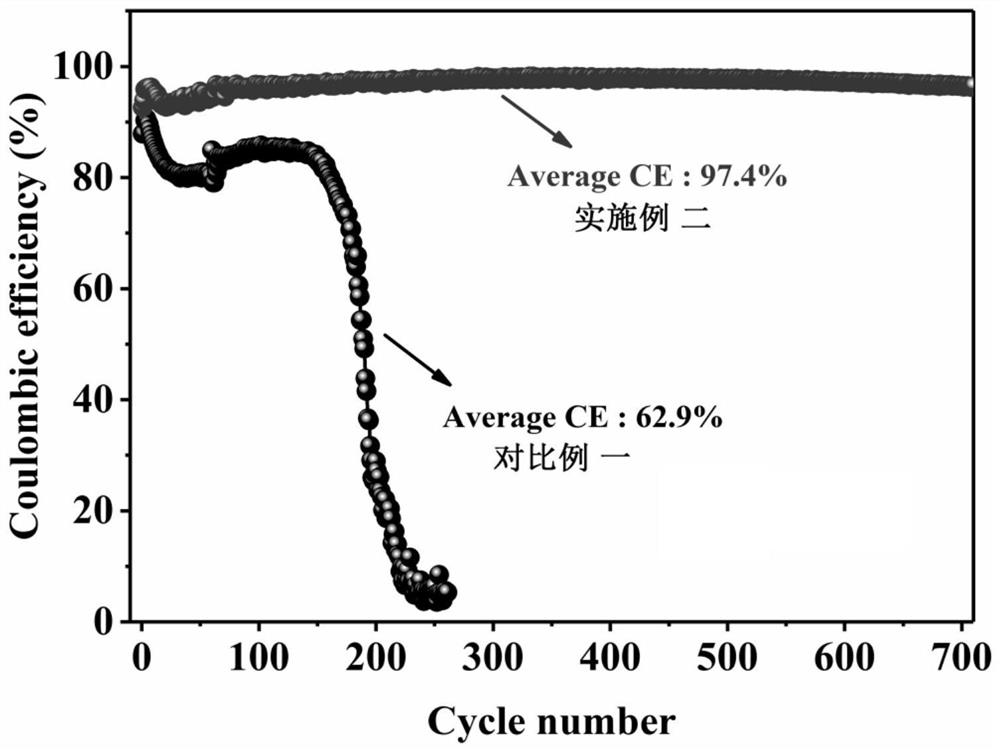

Embodiment 2

[0051] Vinyl ethylene carbonate (VEC) and bis(2,2,2-trifluoroethyl) carbonate (TFEC) are mixed at a volume ratio of VEC:TFEC=1:1, and purified by molecular sieves, calcium hydride, and lithium hydride Miscellaneous, remove water (moisture <10ppm), get mixed solvent;

[0052] At room temperature, the electrolyte lithium salt LiPF 6 Dissolve in the above mixed solvent so that the final concentration of the electrolyte lithium salt is 1.0 mol / L, stir evenly, and leave to stand to obtain a novel electrolyte solution for lithium metal batteries.

[0053] The difference from Example 1 is that VEC and TFEC are mixed at a volume ratio of VEC:TFEC=1:1, and the rest of the steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com