Thick-shell core-shell quantum dots, preparation method thereof and LED

A technology of core-shell quantum dots and quantum dots, which is applied in the field of LED, thick-shell core-shell quantum dots and their preparation, and can solve the problem of restricting the wide application of thick core-shell quantum dots and the difficulty of preparation methods for green light-emitting core-shell quantum dots, etc. problem, to achieve the effect of low cost, controllable wavelength, and narrow half-peak width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Due to the use of low-cost cadmium stearate to prepare green luminous CdSe, a rapid cooling process is required, the reaction is not complete, and there is still a large amount of free Cd in the system. 2+ Existence, the general purification process uses n-hexane / methanol extraction, which can only remove a large amount of ligands and some unreacted precursors, but cannot remove the ions adsorbed on the surface of the quantum dot core.

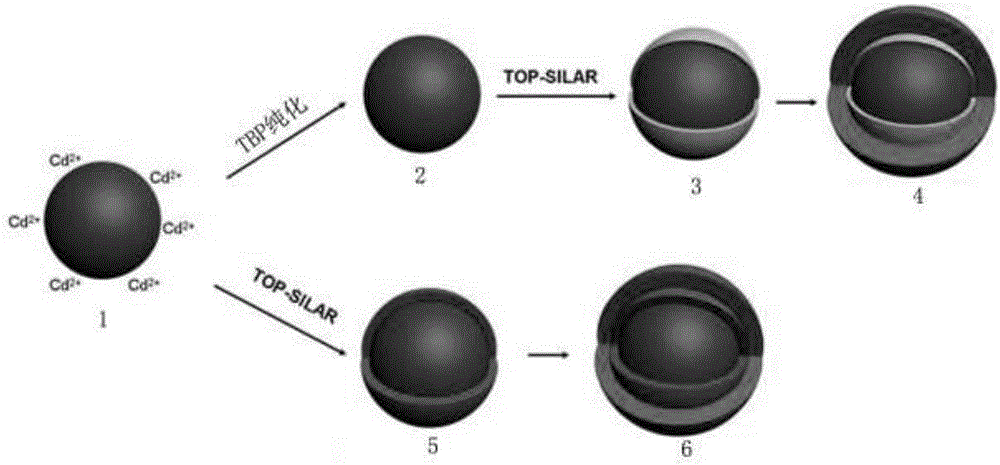

[0055] In this example, TBP is used to activate the surface of the fully reacted CdSe quantum dot core to remove free Cd on the surface. 2 + , and then use the CdSe quantum dots purified by TBP as the core, inject the shell matrix to grow the shell, and the process is as follows figure 1 As shown, 1 is the surface adsorbed Cd 2+ CdSe quantum dot core, 2 is the purified CdSe quantum dot core, 3 is the quantum dot covered with buffer layer, 4 is the thick shell core-shell quantum dot.

[0056] At the same time, compared with the prepar...

Embodiment 2

[0088] Extraction and purification steps: Dissolve the prepared 5nmol quantum dot nuclei in 10mL of n-hexane and 6mL of methanol, then add 100μL of triphenylphosphine reagent, purify 4 times at 40°C, each time for 5min, and obtain quantum dot nuclei without ion adsorption on the surface .

[0089] The preparation of the core-shell quantum dot matrix solution, the preparation of the CdSe core, and the preparation of the CdSe / ZnS core-shell quantum dots can refer to Example 1.

Embodiment 3

[0091] Extraction and purification steps: Dissolve the prepared 5nmol quantum dot nucleus in 30mL of n-hexane and 20mL of methanol, then add 500μL of tri-n-octyl phosphorus reagent, and purify twice at 70°C for 15min each time to obtain quantum dots with no ion adsorption on the surface nuclear.

[0092] The preparation of the core-shell quantum dot matrix solution, the preparation of the CdSe core, and the preparation of the CdSe / ZnS core-shell quantum dots can refer to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com