Blowing method of converter and oxygen lance

A converter blowing and oxygen lance technology, which is applied in the field of metallurgy, can solve problems such as uneven composition and temperature, less obvious bottom blowing effect, and low metal yield, and achieve easy operation, shortened slagging time, and improved metal yield. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

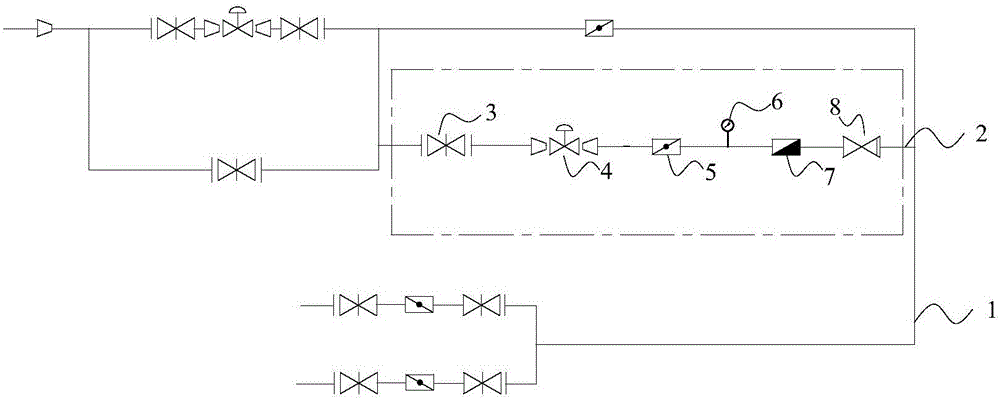

Image

Examples

Embodiment

[0046] After adopting the above-mentioned converter blowing method and oxygen lance in the 150-ton converter area of Baotou Iron and Steel Plant, the phenomenon of failure to fire was effectively reduced during the converter blowing process, and there was no electric field explosion venting and oxygen lance copper head for three consecutive months burnout, which solves the difficult problem of converter ignition.

[0047] In the aspect of removing foam, the metal droplets in the slag are effectively reduced, and the total iron content can be controlled at about 13% through slag sample analysis, which improves the metal yield;

[0048] In terms of continuous production of the converter, it effectively reduces the double slag pouring time of the converter, buffers the burden of converter smelting caused by high ferrosilicon, facilitates the smooth progress of converter smelting, and has a significant effect in improving the hit rate of the end point. objective economic benefit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com