A preparation method of high-purity yttrium oxide coating for key parts of IC equipment

A technology of yttrium oxide and components, which is applied in the field of preparation of high-purity yttrium oxide coatings for key components of IC equipment, can solve the problems of large heat input, easy oxidation, and poor coating quality of aluminum alloy sprayed substrates, and achieve Improve the service life and production efficiency, eliminate oxidation, the effect of dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Cold spraying process parameters: powder feeding gas temperature 600°C, powder feeding gas pressure 2MPa, powder moving speed 1000m / min, spraying distance 20mm, powder feeding rate 100g / min, 4 passes; substrate: 6061 aluminum alloy; The coating thickness obtained after spraying is about 120 μm.

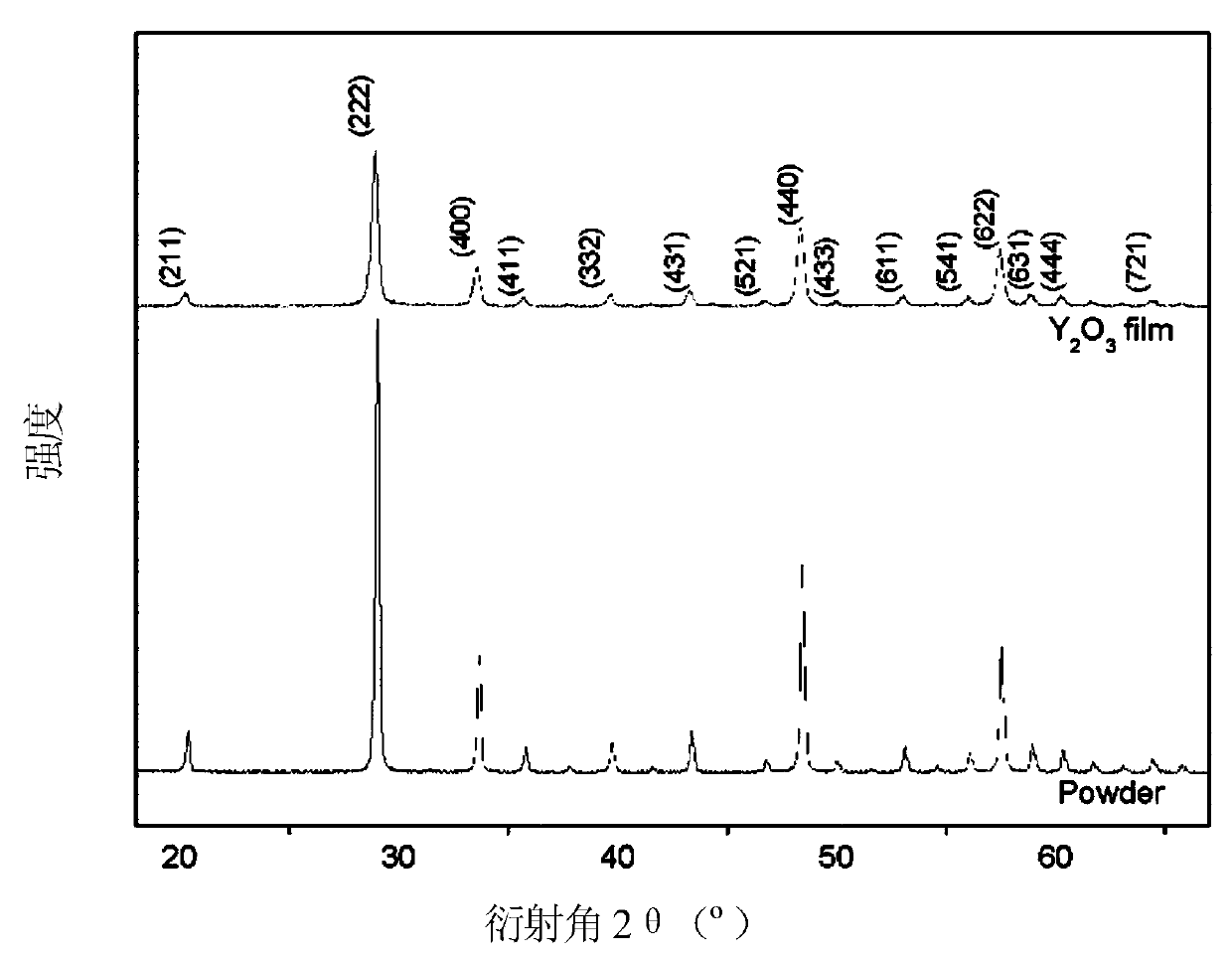

[0037] (1) XRD analysis:

[0038] Such as figure 1 As shown, Y after spraying 2 o 3 Compared with the original powder, the composition of the coating has not changed.

[0039] (2) Surface roughness measurement:

[0040] The average roughness Ra of the cold sprayed coating on the 6061 aluminum alloy substrate is 9.090 μm;

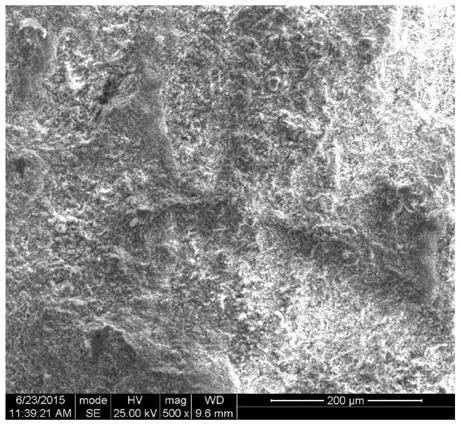

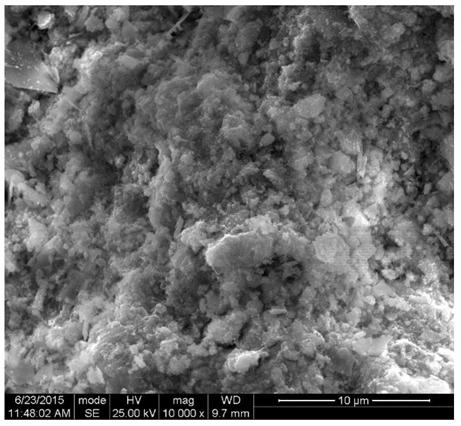

[0041] (3) Surface morphology SEM photos:

[0042] As shown in Figure 2(a)-(b), the surface morphology of the 6061 aluminum alloy substrate;

[0043] (4) Cross-sectional metallographic photos:

[0044] As shown in Figure 3(a)-(b), from Y 2 o3 The metallographic photograph of the coating / 6061 substrate section shows that the coating is well bonded to ...

Embodiment 2

[0046] The difference from Example 1 is that

[0047] Cold spraying process parameters: powder feeding gas temperature 500°C, powder feeding gas pressure 4MPa, powder moving speed 800m / min, spraying distance 20mm, powder feeding rate 80g / min, 6 passes; substrate: 6061 aluminum alloy; The coating thickness obtained after spraying is about 100 μm.

[0048] As shown in Figure 4(a), the surface morphology of the 6061 aluminum alloy substrate; as shown in Figure 4(b), from Y 2 o 3 The metallographic photograph of the coating / 6061 substrate cross-section shows that the coating is well bonded to the substrate and the microstructure is evenly distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com