Method for analyzing products for removing alkene

An analysis method and a technology for removing olefins, which is applied in the field of gas chromatography parallel dual detector analysis, can solve the problems of long analysis time, olefin identification errors, and inability to judge the removal degree of olefin impurities in time, so as to shorten the analysis time and avoid errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Adopt the present invention, measure the deolefin product in [Comparative Example 1]. The experimental conditions of gas chromatography, mass spectrometry detector and hydrogen flame ionization detector are the same as those in [Comparative Example 1].

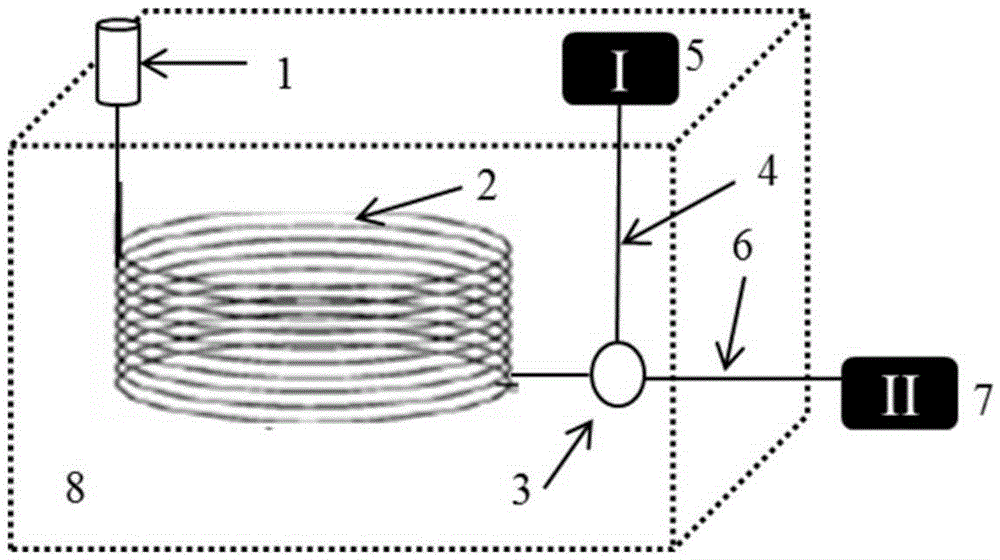

[0028] The capillary column outlet splitter is a three-way plate splitter, the inner wall of each channel in it is inertized, the length is 1.5cm, and the inner diameter is 0.15mm; the length of the first restrictor column is 0.40m, the inner diameter is 0.10mm, The length of the second limiting column is 0.25m, and the inner diameter is 0.10mm, all of which are deactivated elastic quartz capillaries.

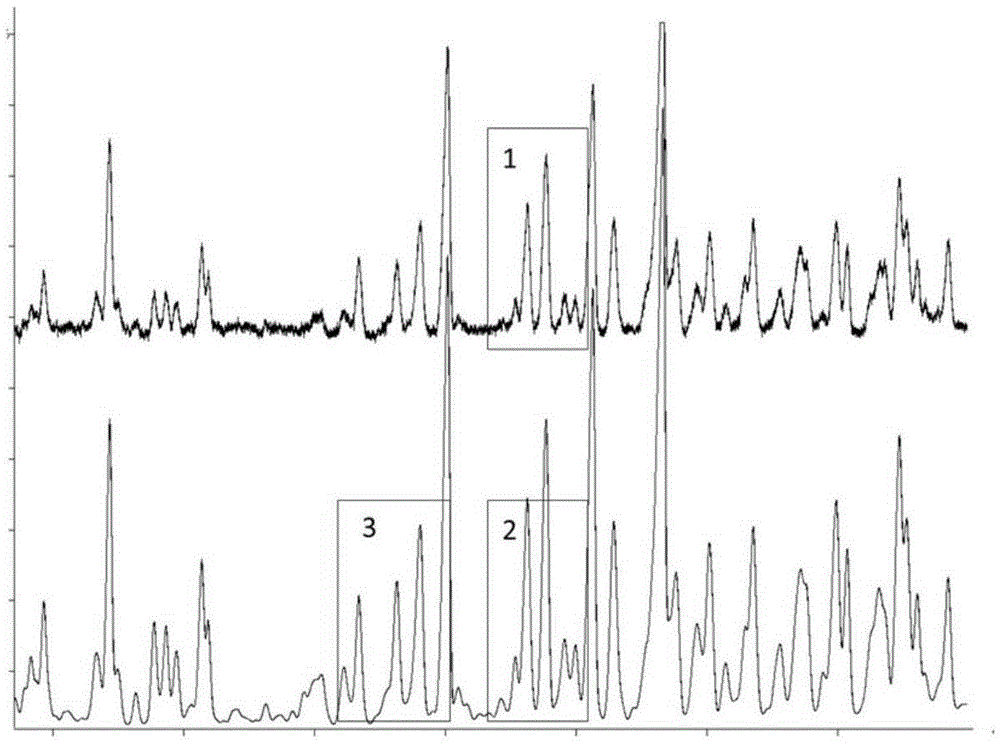

[0029] Such as figure 2 Shown, is the total ion current figure (black line A) and chromatogram (red line B) local enlarged figure of this product on the mass spectrometry detector of the present invention and hydrogen flame ionization detector, each component profile, peak shape and retention There is almost no deviat...

Embodiment 2

[0032] Adopt the present invention, measure the deolefin product in [Comparative Example 1]. The experimental conditions of gas chromatography, mass spectrometry detector and hydrogen flame ionization detector are the same as those in [Comparative Example 1].

[0033] The capillary column outlet splitter is a three-way valve splitter, the inner wall of each channel in it is inertized, the length is 1.0cm, and the inner diameter is 0.10mm; the length of the first restrictor column is 1.0m, the inner diameter is 0.20mm, The length of the second limiting column is 0.40m, and the inner diameter is 0.10mm, all of which are deactivated elastic quartz capillaries.

[0034] Separation by gas chromatography, mass spectrometry detector and hydrogen flame ionization detector simultaneously obtain structure identification and content determination information. The whole running time is only 45 minutes, which is half of the analysis time of [Comparative Example 1], as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com