PID-based double-stage pusher centrifuge control device and method

A control device and centrifuge technology, applied in the direction of program control, electrical program control, general control system, etc., can solve the problems of expensive frequency converter, difficulty in debugging and maintenance, and increased cost of the company, so as to save cost and start current. , the effect of preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

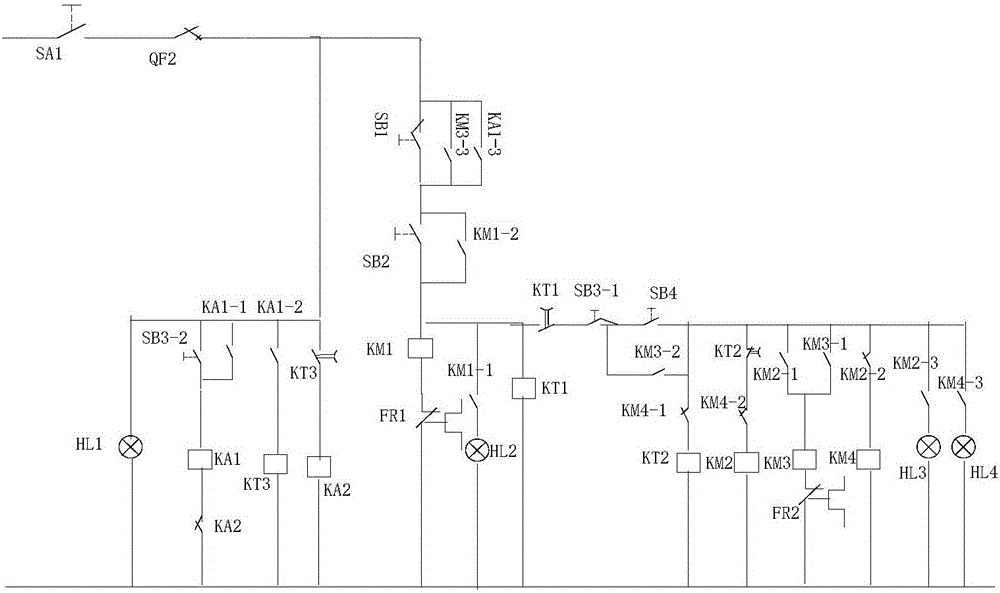

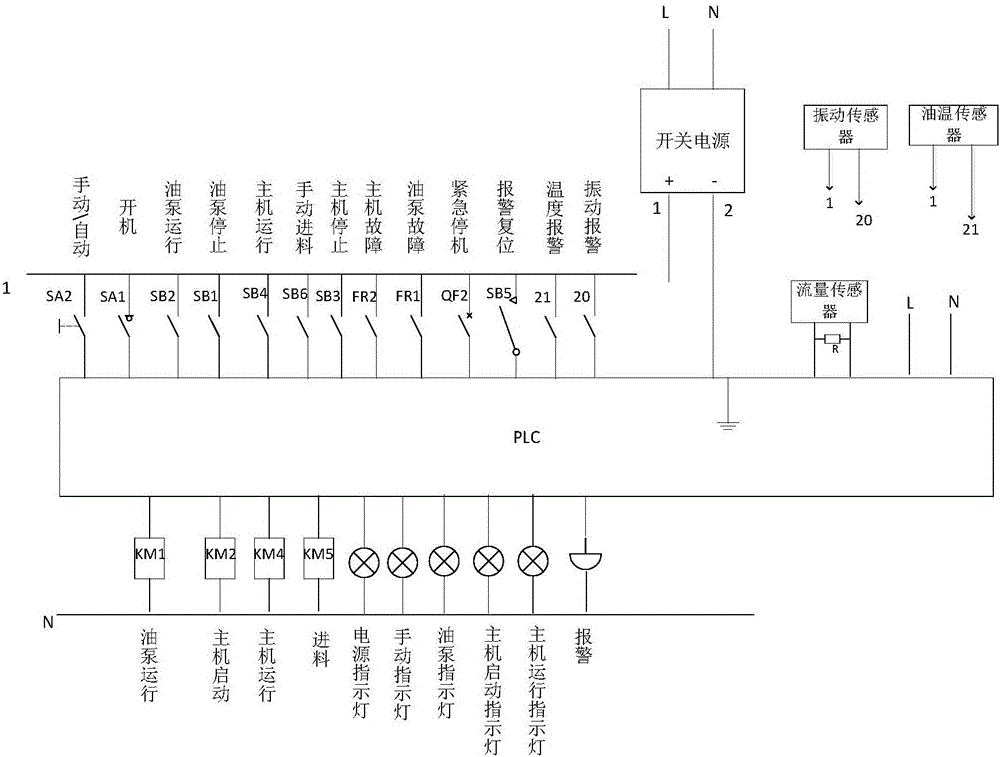

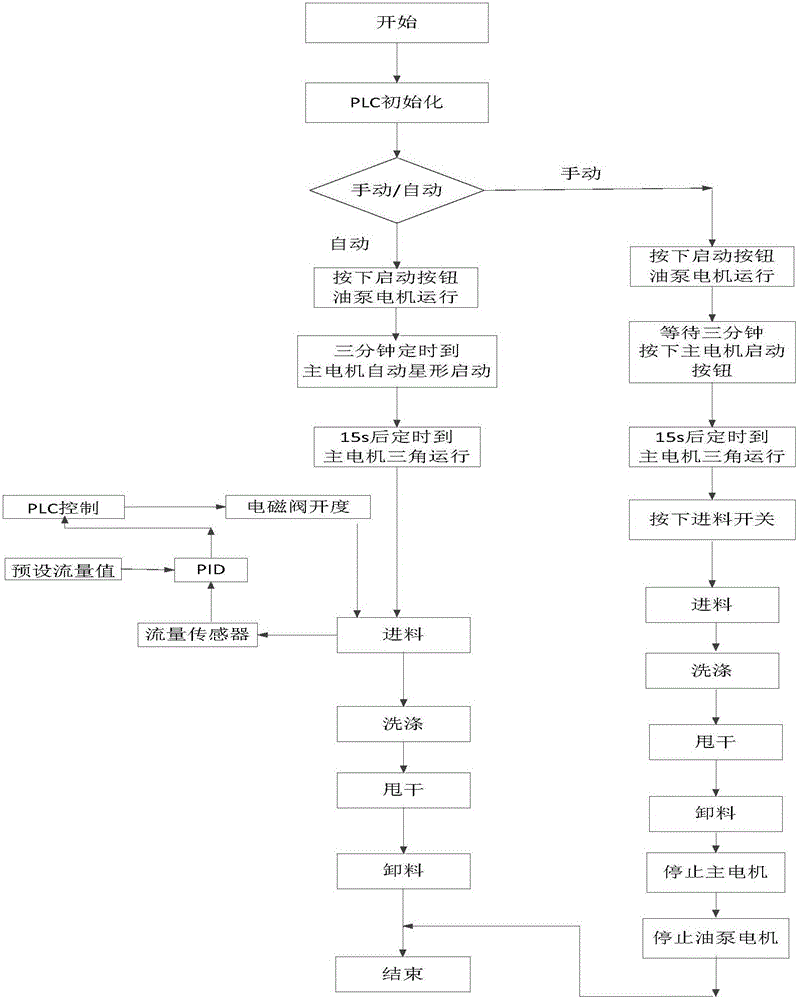

[0028] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0029] Such as Figure 4 , Figure 5 As shown, the two-stage pusher centrifuge mainly includes a material tube 1, an outer drum 4, an inner drum 3, a hydraulic propulsion system 9, a pushing disc 10, a distributing disc 2, and a main motor ( Figure 5 not shown), oil pump motor ( Figure 5 not shown) and feed solenoid valve ( Figure 5 not shown in the figure), the outer drum 4 and the inner drum 3 are sequentially arranged from the outside to the inside and communicate with each other. connection; the material pipe 1 communicates with the distribution pan 2, and the distribution pan 2 is connected with the push pan 10; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com