A kind of semiconductor device and its preparation method, electronic device

A technology of electronic devices and semiconductors, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as increased loss, increased epitaxial resistance, and reduced performance of FinFET devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

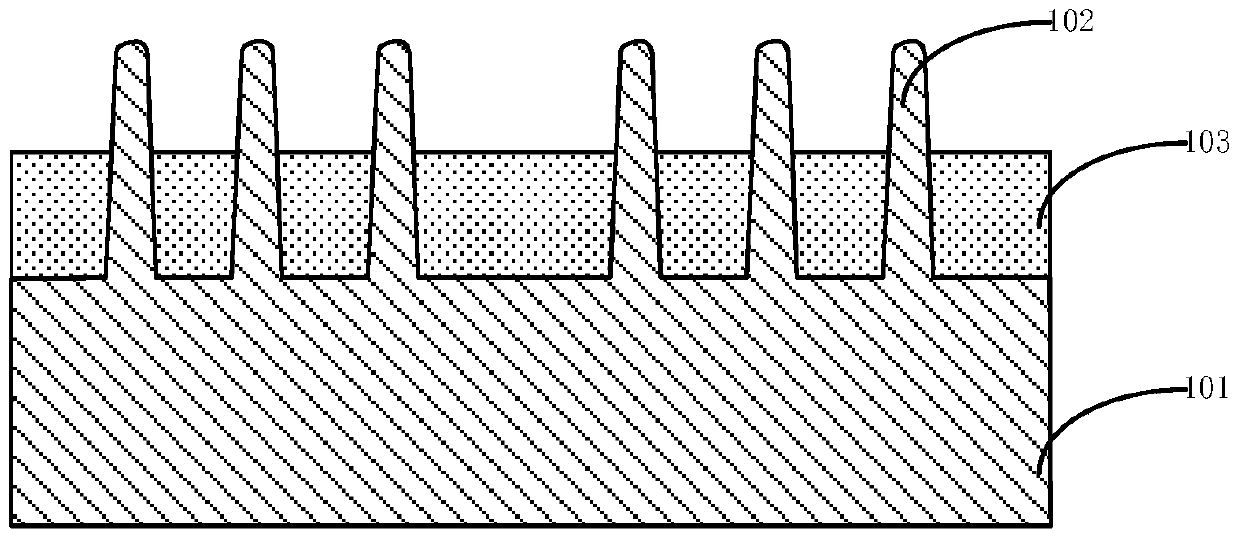

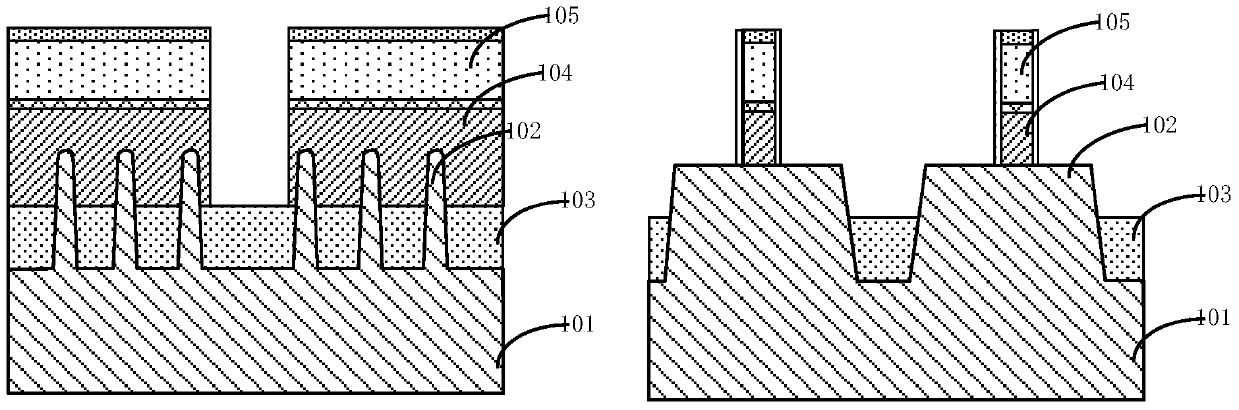

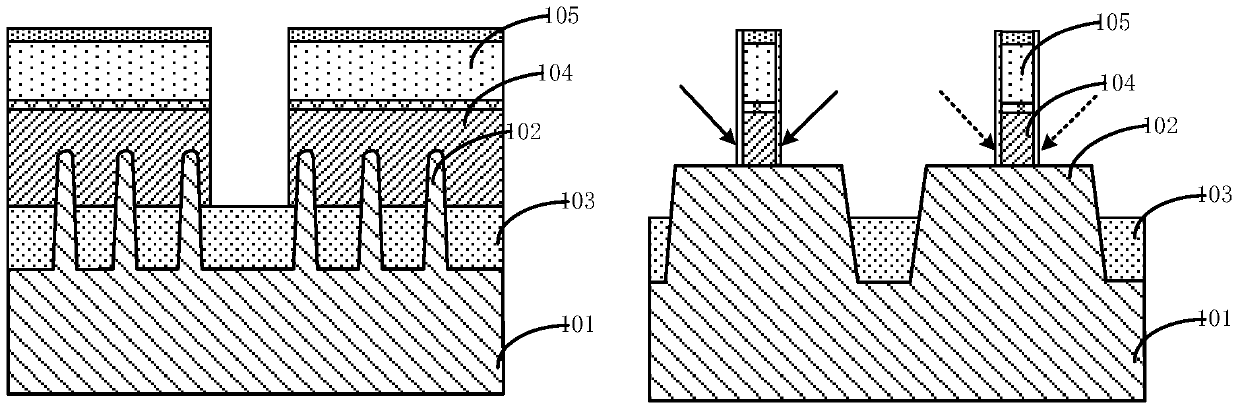

[0039] Combine below Figures 1a-1j , figure 2 The semiconductor device and the preparation method of the present invention are further described.

[0040] Step 201 is executed to provide a semiconductor substrate 101 and perform ion implantation to form a well.

[0041]In this step, the semiconductor substrate 101 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S- SiGeOI), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0042] Wherein the semiconductor substrate includes an NMOS region and a PMOS region, so as to form NMOS devices and PMOS devices in subsequent steps.

[0043] Next, a pad oxide layer (Pad oxide) is formed on the semiconductor substrate 101, wherein the formation method of the pad oxide layer (Pad oxide) can be formed by a deposition method, such as chemical vapor deposition, atomic layer deposition, etc. , can also be f...

Embodiment 2

[0099] The present invention also provides a semiconductor device, including a semiconductor substrate 101 and a well.

[0100] The semiconductor substrate 101 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI), insulator Silicon germanium-on-insulator (SiGeOI) and germanium-on-insulator (GeOI), etc.

[0101] Wherein the semiconductor substrate includes an NMOS area and a PMOS area to form an NMOS device and a PMOS device.

[0102] A plurality of fins 102 are formed on the semiconductor substrate 101, and the widths of the fins are all the same, or the fins are divided into a plurality of fin groups with different widths.

[0103] An isolation material layer 103 is formed between the fins and partially covers the fin structure.

[0104] A gate structure surrounding the fin is formed on the isolation material layer, and the gate structure includes an NMOS gate struct...

Embodiment 3

[0115] The present invention also provides an electronic device, including the semiconductor device described in the second embodiment. Wherein, the semiconductor device is the semiconductor device described in the second embodiment, or the semiconductor device obtained according to the preparation method described in the first embodiment.

[0116] The electronic device of this embodiment can be any electronic product or equipment such as mobile phone, tablet computer, notebook computer, netbook, game console, TV set, VCD, DVD, navigator, camera, video recorder, voice recorder, MP3, MP4, PSP, etc. , can also be any intermediate product including the semiconductor device. The electronic device according to the embodiment of the present invention has better performance due to the use of the above-mentioned semiconductor device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com