Catalyst for producing low-carbon olefins by dehydrogenation of low-carbon alkanes and preparation method thereof

A technology for low-carbon alkanes and low-carbon olefins, which is applied in the field of catalyst carriers and their preparation, can solve the problems of short single-pass life, rapid conversion rate decline, and rapid catalyst carbon deposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

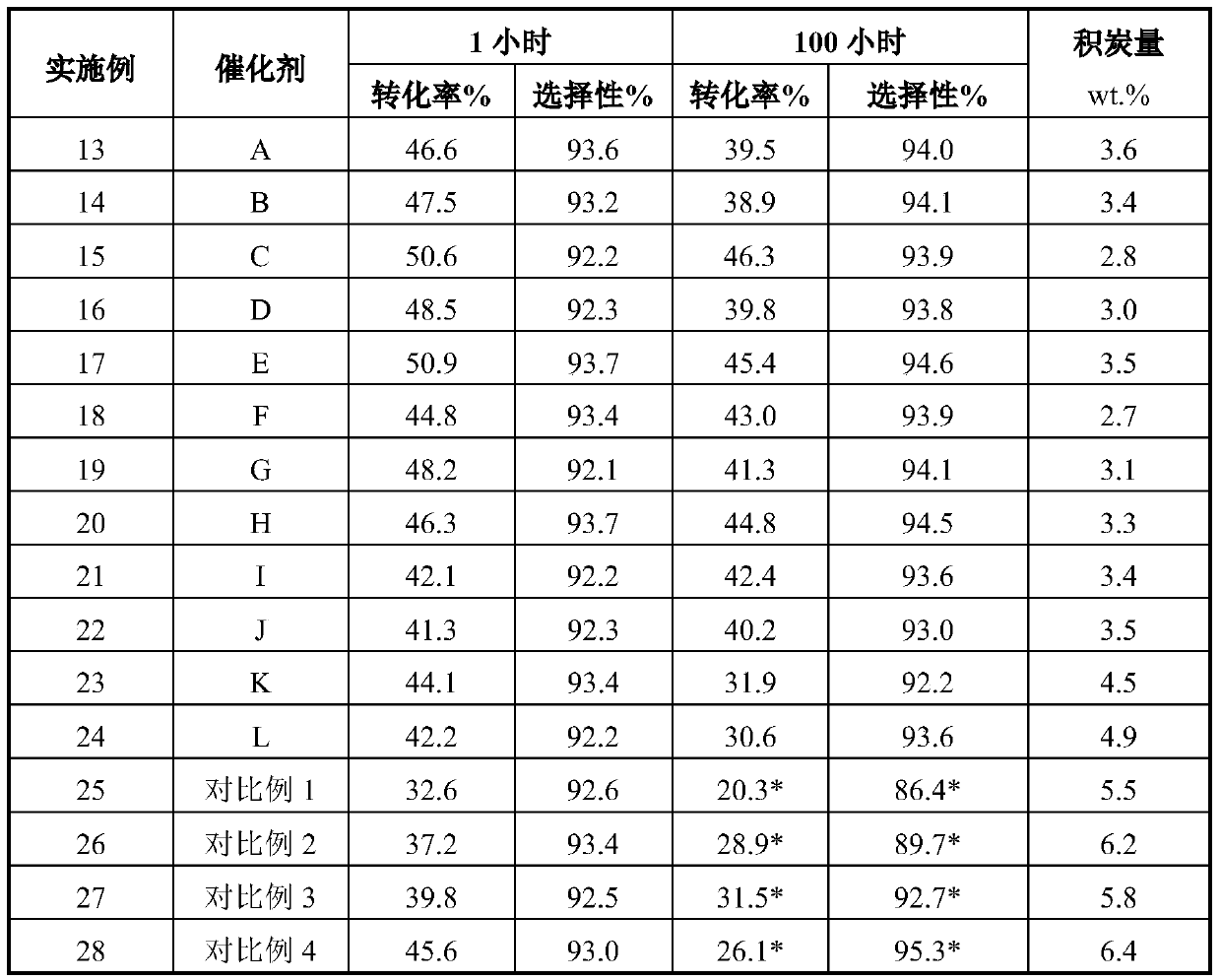

Examples

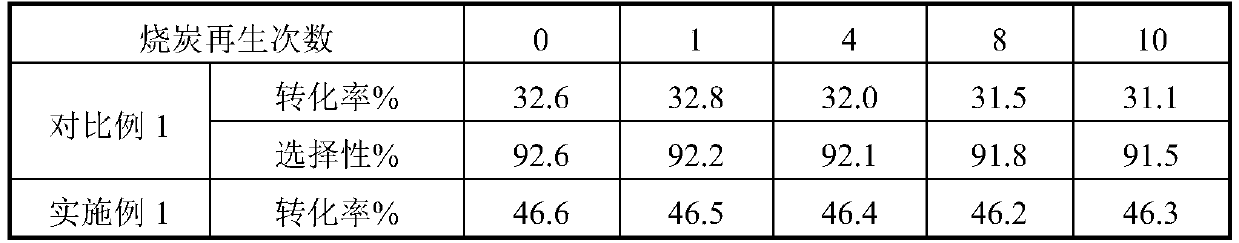

Embodiment 1

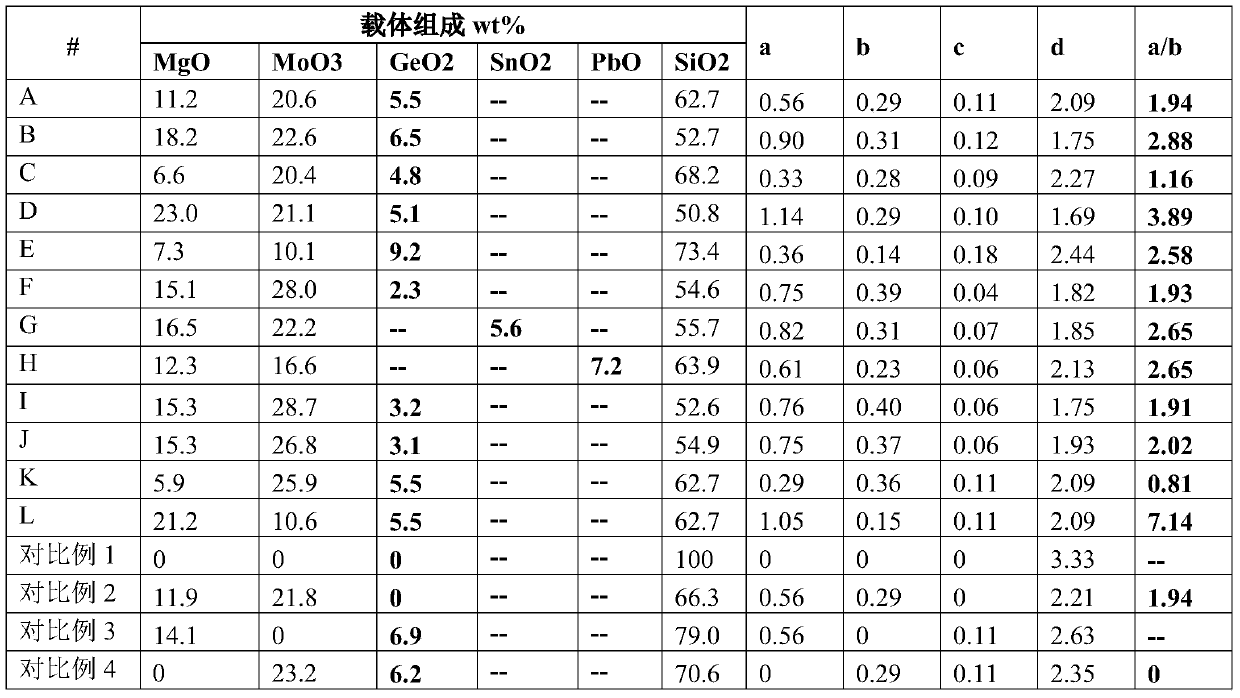

[0027] Get 142.52g magnesium nitrate (Mg(NO 3 ) 2 6H 2 O), 56.1g ammonium molybdate ((NH 4 ) 2 MoO 4 ) was dissolved in 1000ml of deionized water, and then 125.4g of silicon dioxide (80-120 microns in particle size) and 11.0g of germanium oxide (80-120 microns in particle size) were added to form a suspension; at 25°C, under vigorous stirring, the Slowly add 6% ammonia water dropwise into the mixed aqueous solution to form a precipitate, control the pH value to 8.0, stir for 2 hours, filter, wash with deionized water for 3 times, dry at 120°C, pulverize, and sieve at 700 ℃ for 16 hours to obtain a composite silica carrier. Pore volume 0.56cm 3 / g, specific surface area 95m 2 / g. The composition and properties of the carrier are shown in Table 1.

[0028] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2O, 0.12g) i...

Embodiment 2

[0031] Get 231.5g magnesium nitrate (Mg(NO 3 ) 2 6H 2 O), 61.55g ammonium molybdate ((NH 4 ) 2 MoO 4 ) was dissolved in 1000ml of deionized water, and then 105.4g of silicon dioxide (76-110 microns in particle size) and 13.0g of germanium oxide (50-90 microns in particle size) were added to form a suspension; at 25°C, under vigorous stirring, the Slowly add 10% ammonia water dropwise into the mixed aqueous solution to form a precipitate, control the pH value to 8.0, stir for 2 hours, filter, wash with deionized water for 3 times, dry at 120°C, pulverize, and sieve at 760 ℃ for 12 hours to obtain a composite silica carrier. Pore volume 0.68cm 3 / g, specific surface area 116m 2 / g. The composition and properties of the carrier are shown in Table 1.

[0032] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.12g)...

Embodiment 3

[0035] Get 83.98g magnesium nitrate (Mg(NO 3 ) 2 6H 2 O), 55.56g ammonium molybdate ((NH 4 ) 2 MoO 4 ) was dissolved in 1000ml of deionized water, and then 136.4g of silicon dioxide (30-80 microns in particle size) and 9.6g of germanium oxide (60-90 microns in particle size) were added to form a suspension; at 25°C, under vigorous stirring, the Slowly add 10% ammonia water dropwise into the mixed aqueous solution to form a precipitate, control the pH value to 8.0, stir for 2 hours, filter, wash with deionized water for 3 times, dry at 120°C, pulverize, and sieve at 760 ℃ for 12 hours to obtain a composite silica carrier. Pore volume 0.70cm 3 / g, specific surface area 105m 2 / g. The composition and properties of the carrier are shown in Table 1.

[0036] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.12g) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com