Accurately-positioning molding method capable of controlling bonding mud amount and device using method

A technology of precise positioning and forming method, which is applied in supply devices, ceramic forming machines, ceramic forming workshops, etc., can solve the problems of high moisture content of blanks, difficult to control the size of the bottle mouth, high labor intensity, etc., and achieve the dimensional accuracy of the bottle mouth. The effect of high, good thermal stability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

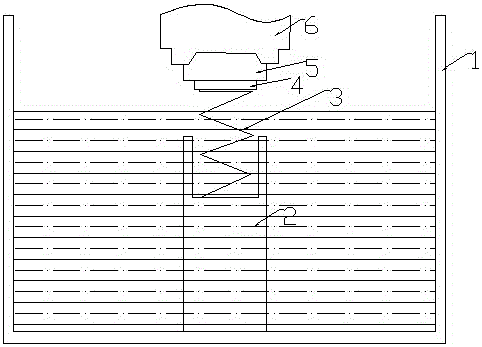

Image

Examples

Embodiment Construction

[0017] The ceramic bottle mouth provided by the present invention can be accurately positioned and can control the forming method of the amount of bonding mud. The main technical circuit of the present invention is:

[0018] 1. Model making: Design the upper and lower mold opening methods of the model, pour the working mold, dry and inspect.

[0019] 2. Slurry preparation: material selection, batching, ball milling for 35 hours, 100-mesh sieving to remove iron, pressure filtration, stale for 3 days, ball milling, 100-mesh sieving to remove iron.

[0020] 3. Glaze preparation: material selection, batching, ball milling for 48 hours, 200-mesh sieving to remove iron, staling for 3 days.

[0021] 4. Molding: grouting molding, blank trimming machine processing, inspection.

[0022] specific:

[0023] (1) First of all, in terms of the design of the plaster model, the upper and lower mold opening methods are used to remake the mold, and the joint parts of the model for the bottle m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com