Wear-resistant additive for low-sulfur diesel oil as well as preparing method thereof and diesel oil combination

A low-sulfur diesel and additive technology, used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of rotary pump distribution pump wear, reduce service life, reduce diesel natural lubrication performance, etc., to improve lubricity, The effect of rust improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

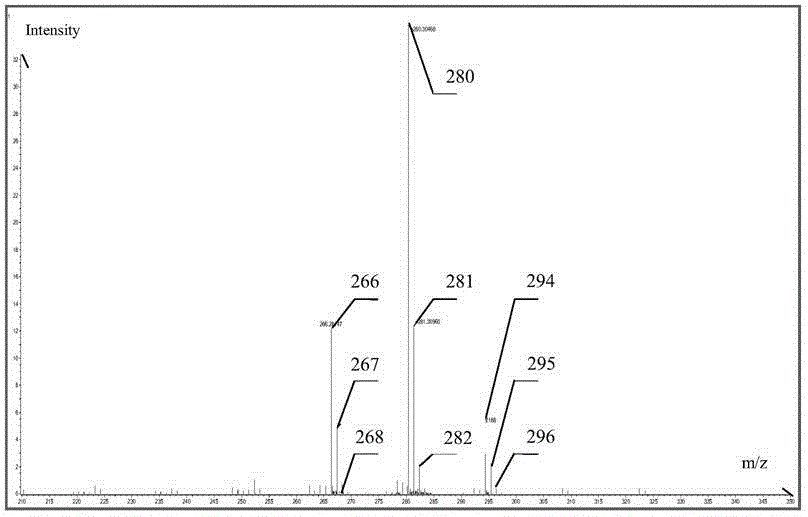

[0036] This example is the preparation of alkenyl substituted hydrazides.

[0037] Place 50g (0.19mol) of dodecenylsuccinic anhydride and 6.0g (0.19mol) of hydrazine in a three-necked flask reactor equipped with an electric stirrer, a thermometer, a reflux water separator and a nitrogen inlet pipe, and feed into The temperature was controlled at 30° C. under nitrogen heating and stirring, and nitrogen purging was used to react for 1 hour, and the product was formed.

example 2

[0039] This example is the preparation of alkenyl hydrazide.

[0040] Put 50g (0.19mol) dodecenylsuccinic anhydride, 11.2g (0.19mol) hydrazine hydrate (85%, wt) in a three-necked flask equipped with an electric stirrer, a thermometer, a reflux water separator and a nitrogen inlet tube In the reactor, feed nitrogen to heat and stir to raise the temperature to 150-160° C., purging and reacting with nitrogen for 3 hours, and the product is produced.

example 3

[0042] This example is the preparation of alkenyl substituted hydrazides.

[0043] 50g (0.19mol) dodecenyl succinic anhydride and 11.4g (0.19mol) ethylhydrazine are placed in a three-necked flask reactor equipped with an electric stirrer, a thermometer, a reflux water separator and a nitrogen inlet pipe, and the The temperature was controlled at 80° C. under nitrogen gas heating and stirring, and the reaction was carried out by purging nitrogen gas for 5 hours, and the product was formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com