Thin-wall local heat transfer coefficient measuring method based on thermal fluctuation coupling infrared imaging

A heat transfer coefficient measurement and infrared imaging technology, which is applied in measuring devices, optical radiation measurement, radiation pyrometry, etc., can solve the problem that the angle coefficient of the infrared camera lens and the surface to be measured is difficult to reach the nominal condition, and the temperature measurement is accurate The performance cannot be guaranteed and other problems, and achieve the effect of fast measurement speed and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

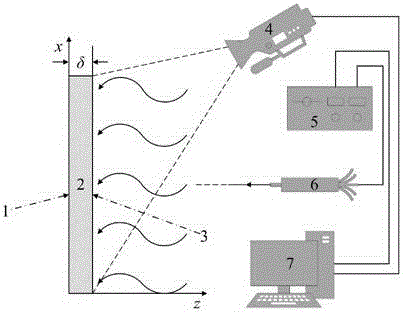

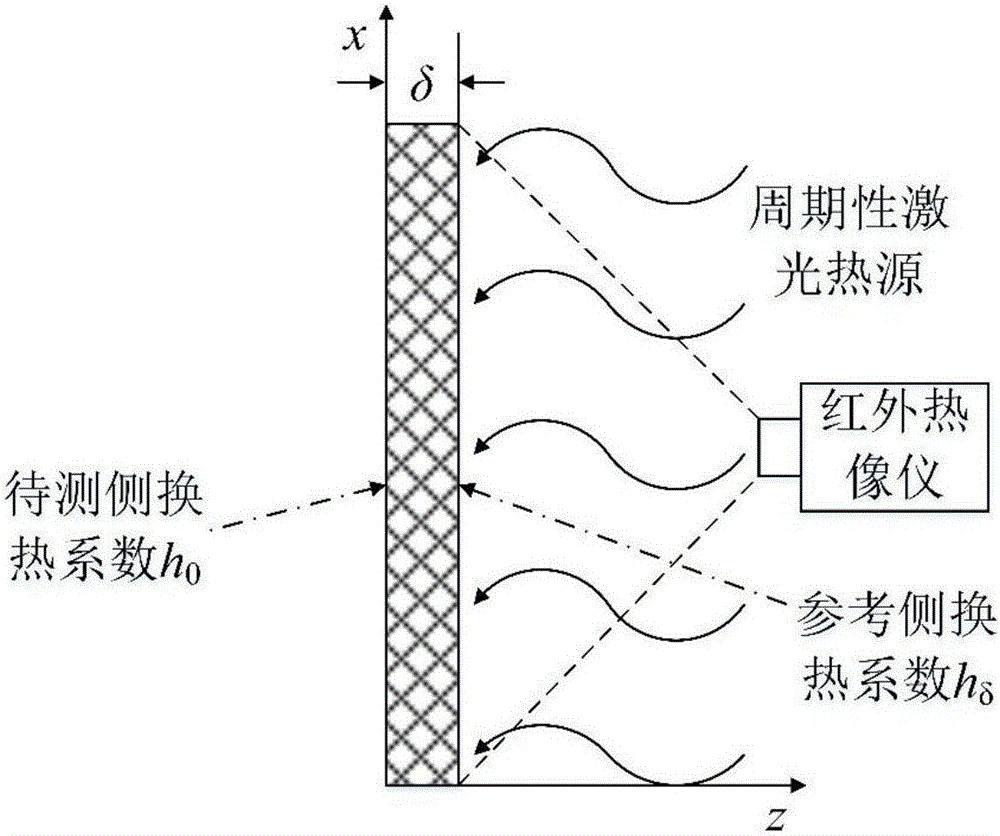

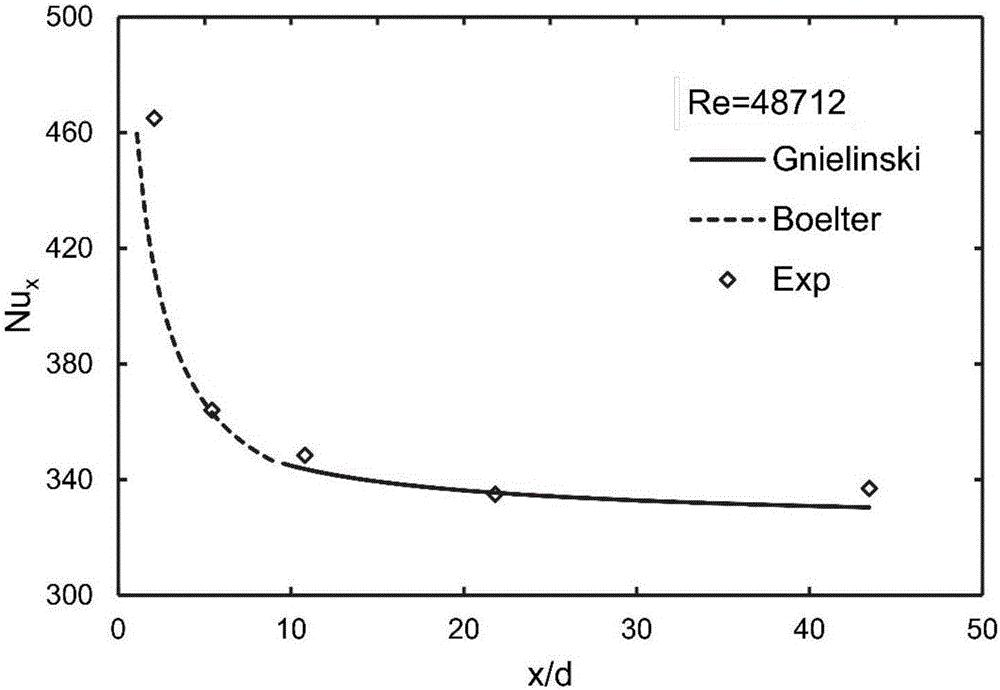

[0048] Such as figure 1 , figure 2 and image 3 As shown, the thin-walled local heat transfer coefficient measurement method based on thermal fluctuation coupled infrared imaging, the system consists of the thin-walled feature area to be measured 1, the thin-walled feature to be measured section 2, and the thin-walled feature reference side corresponding to the area to be measured 3 , an infrared camera 4, a programmable DC power supply 5, a laser generator 6, and a computer 7. Known thin-wall thickness δ, thin-wall material thermal diffusivity a, thin-wall material thermal conductivity k, and thin-wall reference side heat transfer coefficient h δ Under the condition of (during the measurement process, the main flow temperature of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com