A power transmission system of a cutting and longitudinal flow threshing and separating device

A technology of threshing separation and power transmission, which is used in threshing equipment, cutters, agricultural machinery and implements, etc., can solve the problem that the transmission chain is easy to interfere with the side wall of the frame, the power loss of the transmission shaft is too long, and it is difficult to arrange tension. equipment and other problems, to achieve the effect of reducing power transmission distance, compact structure and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

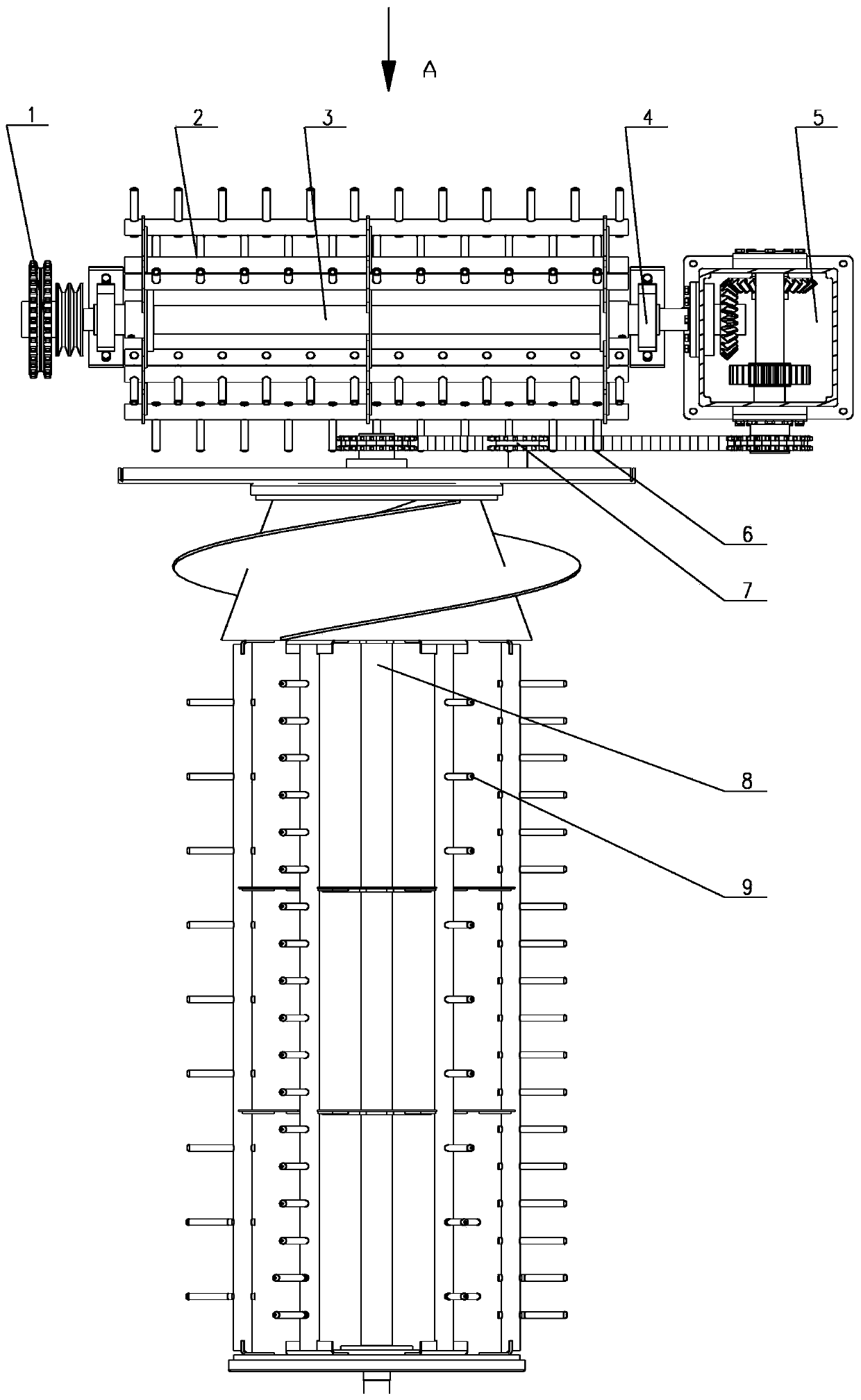

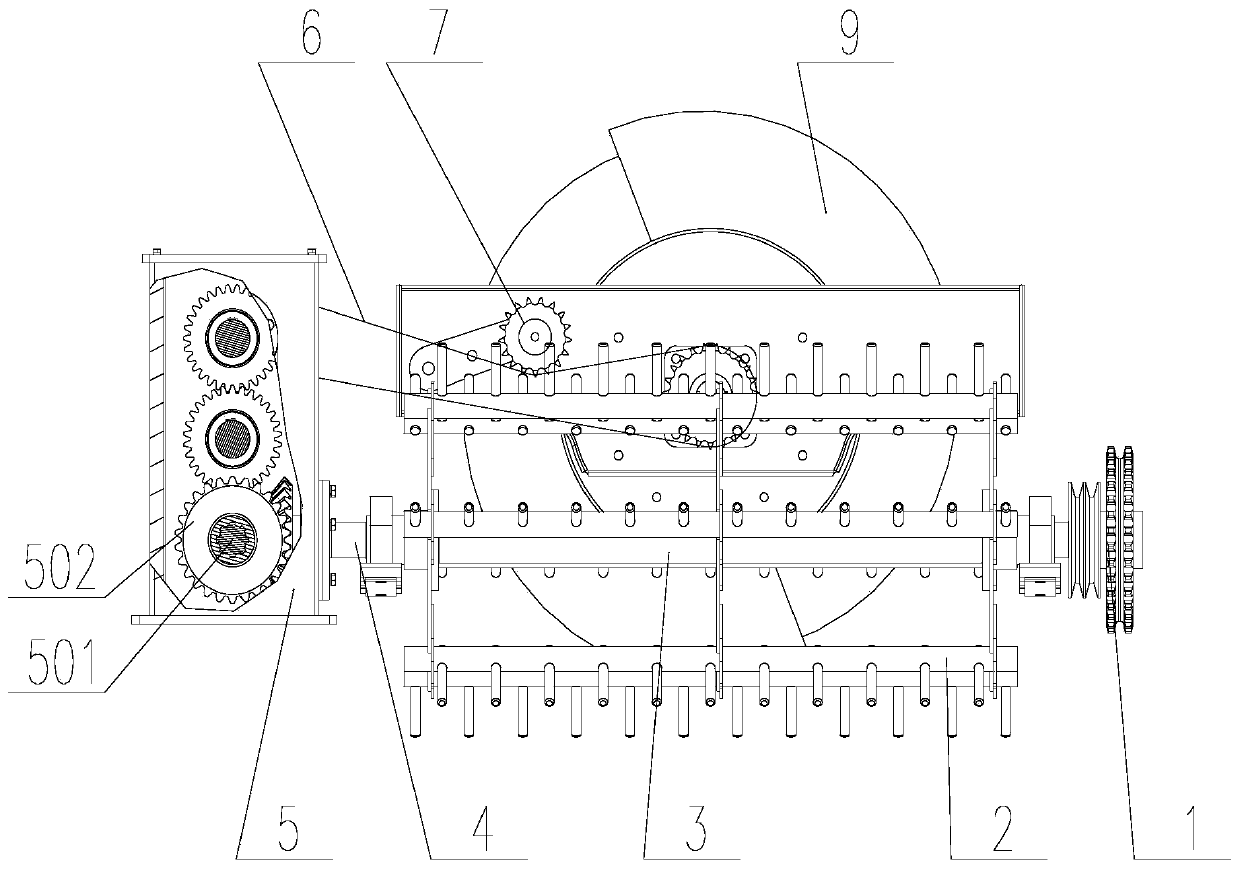

[0032] figure 1 Shown is an embodiment of the power transmission system of the tangential and longitudinal flow threshing and separating device of the present invention. The power transmission system of the tangential and longitudinal flow threshing and separating device includes a tangential flow drum 2, a gear transmission box 5, a transmission member 6, a Tightening device 7 and vertical axial flow drum 9.

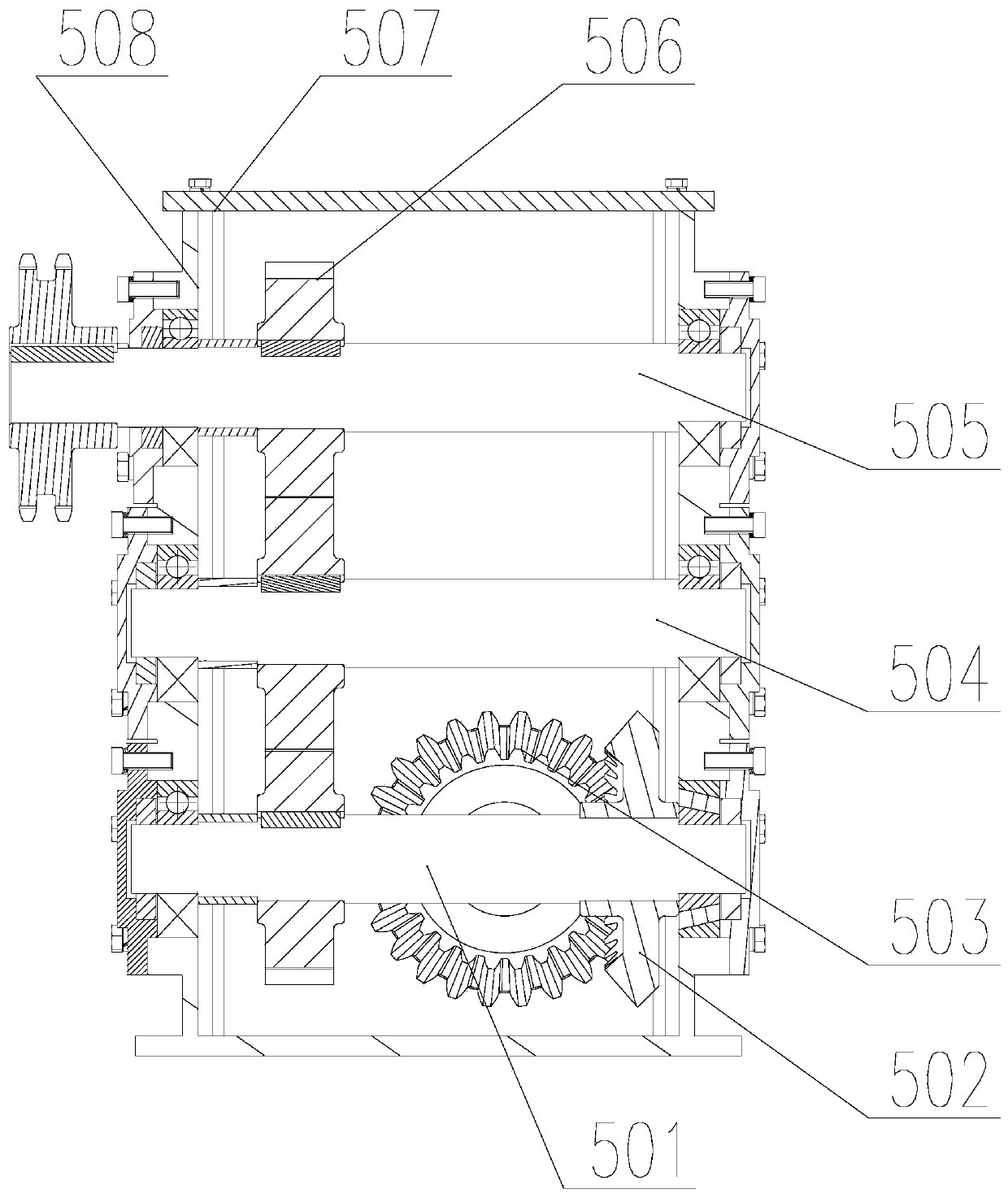

[0033]The cutting flow drum 2 and the vertical axial flow drum 9 are placed perpendicular to each other; the horizontal cutting flow drum 2 is provided with a cutting flow drum shaft 3, and the two ends of the cutting flow drum shaft 3 pass through the two ends of the cutting flow drum 2 and They are respectively connected to the power input end 1 and the power output end 4, the power input end 1 is connected to the engine output shaft through a transmission structure, the cut-flow drum shaft 3 of the power output end 4 is directly inserted into the gear transmission bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com