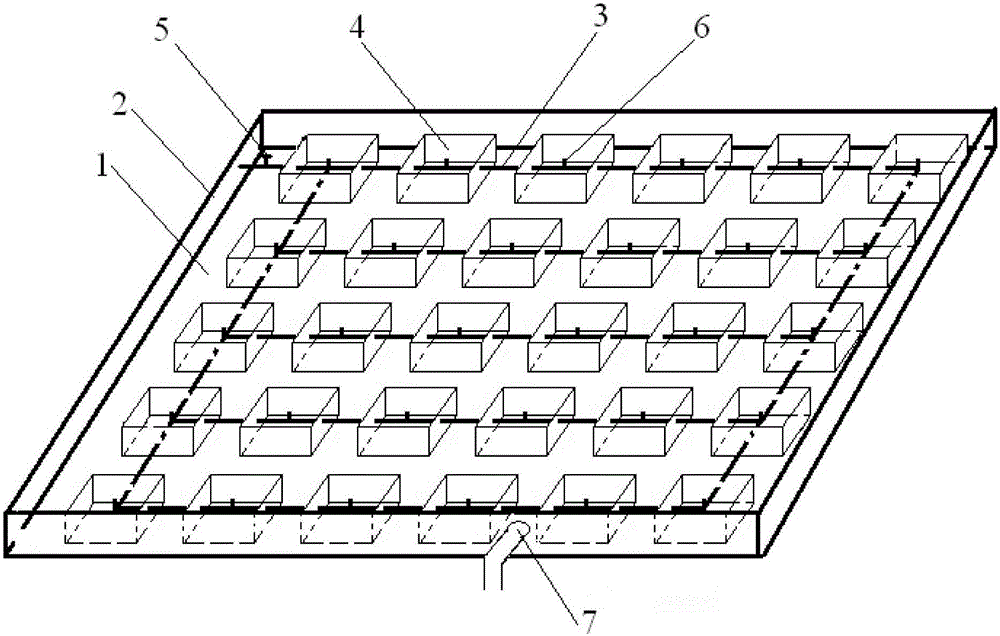

Fabricated type passive greening system for roof

A prefabricated and passive technology, applied in roof decoration, building roofs, roofing, etc., can solve the problems of high maintenance cost, cumbersome construction, and large roof greening load, and achieve low maintenance cost, simple construction, and good water storage capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Planting ponds, made by the following methods:

[0018] According to the mass ratio of 60:25:6:10:4:15:1:3.5:5, low-alkali sulphoaluminate cement, ordinary Portland cement, fly ash, slag, plant ash, humus, Diammonium hydrogen sulfate, ferric sulfate and hydrogen peroxide are used as raw materials. The mass ratio of water to raw materials is 0.4. Add water, mix evenly, foam, carbonize, cut and shape, and assemble.

Embodiment 2

[0020] Planting ponds, made by the following methods:

[0021] According to the mass ratio of 50:30:2:15:2:20:1:2:8, low-alkali sulphoaluminate cement, ordinary Portland cement, fly ash, slag, plant ash, humus, Diammonium hydrogen sulfate, ferric sulfate and hydrogen peroxide are used as raw materials. The mass ratio of water to raw materials is 0.3. Add water, mix evenly, foam, carbonize, cut and shape, and assemble.

Embodiment 3

[0023] Planting ponds, made by the following methods:

[0024] According to the mass ratio of 70:20:10:5:5:10:1:4.5:3, low-alkali sulphoaluminate cement, ordinary Portland cement, fly ash, slag, plant ash, humus, Ammonium bisulfate, ferric sulfate and hydrogen peroxide are used as raw materials. The mass ratio of water to raw materials is 0.5. Add water, mix evenly, foam, carbonize, cut and shape, and assemble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com