High-protein dietary fiber energy protein bar and production method thereof

A dietary fiber and protein bar technology, which is applied in the field of food processing, can solve the problems of short shelf life and achieve the effect of being easy to carry, convenient to eat, and good in taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

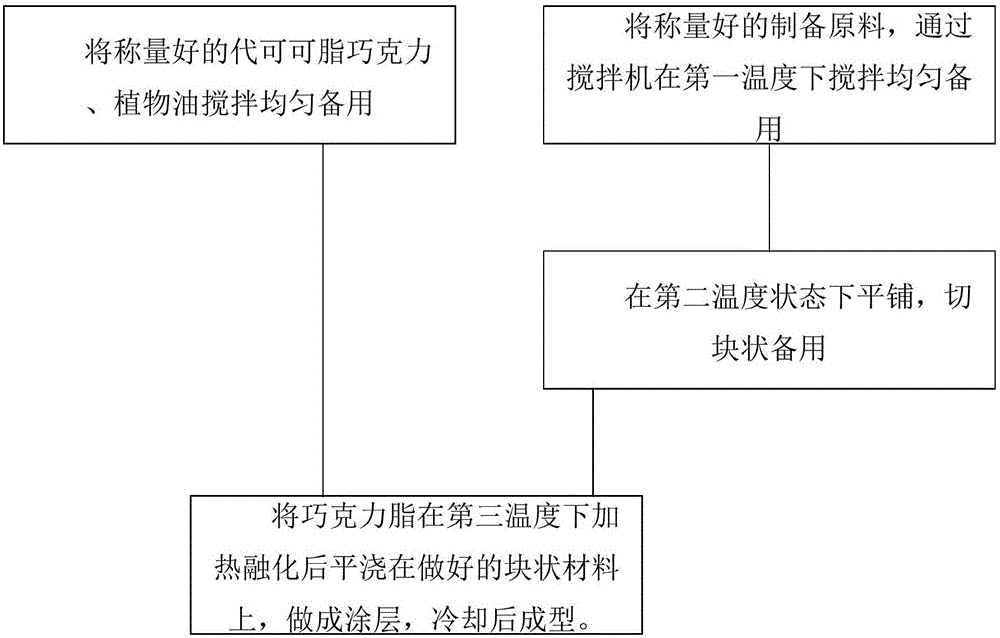

[0121] (1), weighing the weight ratio is 9-31 parts of cocoa butter substitute chocolate (dark or white chocolate) and 3-9 parts of vegetable oil and stirring evenly for later use;

[0122] (2), the weighing ratio is 5-35 parts of granular soybean protein, 3-29 parts of glucose syrup, 0-18 parts of isomalto-oligosaccharide, and 3-8 parts of concentrated whey protein powder through the mixer at the first temperature Stir well and set aside;

[0123] (3), the material obtained in step (2) is tiled under the second temperature state, and cut into pieces for subsequent use;

[0124] (4) Heat and melt the material in step (1) at the third temperature and pour it flat on the block material obtained in step (3) to form a coating, and shape it after cooling to obtain a protein bar.

[0125] In this embodiment, in step (2), one or more of the following raw material components can be added according to actual needs: 0-11 parts of puffed rice; 0-6 parts of purple potato chips; 0-5 parts...

Embodiment 2

[0127] (1), the weight ratio of weighing is 20 parts of cocoa butter chocolate and 3 parts of vegetable oil, stir evenly and set aside;

[0128] (2) The weighing ratio is 30 parts of granular soybean protein, 13 parts of glucose syrup, 6 parts of concentrated whey protein powder, 2 parts of maltitol, 3 parts of citrus fiber, 3 parts of wheat fiber, 9 parts of puffed rice, hazelnut 0-5 parts of grains, 1 part of chia seeds, 2 parts of desiccated coconut, 2 parts of strawberry powder, 0.5 parts of milk mineral salt, 0.5 parts of psyllium husk powder, 2 parts of chopped peach kernels, 0.5 parts of coconut oil, 0.5 parts of glycerin , 0.5 part of soybean lecithin, and 0.5 part of edible salt are stirred evenly at the first temperature by a mixer for subsequent use;

[0129] (3), the material obtained in step (2) is tiled under the second temperature state, and cut into pieces for subsequent use;

[0130] (4) Heat and melt the material in step (1) at the third temperature and pour...

Embodiment 3

[0132] (1), the weight ratio of weighing is 20 parts of cocoa butter chocolate and 3 parts of vegetable oil, stir evenly and set aside;

[0133] (2) The weighing ratio is 30 parts of granular soybean protein, 13 parts of glucose syrup, 6 parts of concentrated whey protein powder, 3 parts of anhydrous butter, 9 parts of puffed rice, 3 parts of maltitol, and 3 parts of chia seeds , 2 parts of hazelnuts, 3 parts of shredded coconut, 0.5 parts of milk mineral salt, 3 parts of raisins, 1 part of strawberry powder, 1 part of peanuts, 0.5 parts of coconut oil, 0.5 parts of glycerin, 0.5 parts of soybean lecithin, 0.5 parts of edible salt through the blender Stir evenly at the first temperature for later use;

[0134] (3), the material obtained in step (2) is tiled under the second temperature state, and cut into pieces for subsequent use;

[0135] (4) Heat and melt the material in step (1) at the third temperature and pour it flat on the block material obtained in step (3) to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com