Method for preparing dicalicium phosphate anhydrous (DCPA) bioceramic coating on surface of pure titanium

An anhydrous calcium hydrogen phosphate and bioceramic technology, applied in the field of surgical implants, can solve the problems of incomplete coverage of the matrix, high safety performance requirements, high current or high temperature, etc., and achieve the promotion of stem cell osteogenic differentiation and safety requirements. Low, pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

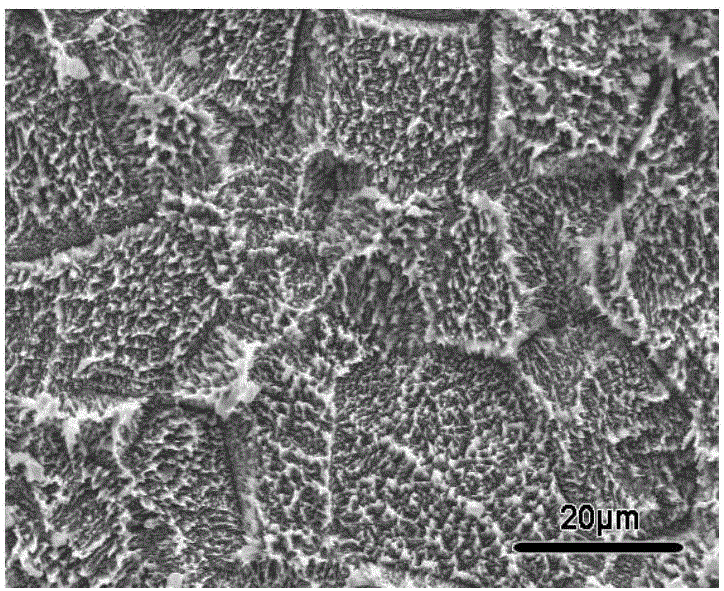

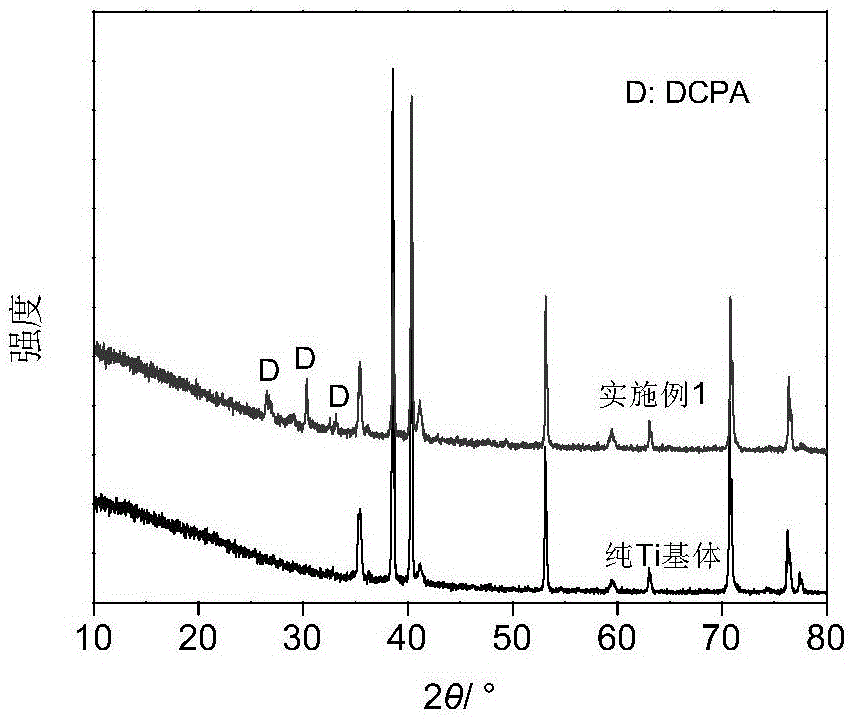

[0021] Weigh 5 g of analytically pure DCPA powder with an electronic balance, transfer it to a glass beaker, add 96 mL of deionized water, add 4 moL of dilute hydrochloric acid HCl with a concentration of 0.04 mol / L, stir with a glass rod, and wait until CaHPO 4 After complete dissolution, transfer the solution to a PET tie-top spray bottle. Sandpaper-polished and ultrasonically cleaned pure titanium was treated in a mixed solution of hydrochloric acid-sulfuric acid at 70°C for 30 minutes, and then rinsed with a large amount of deionized water to obtain a super-hydrophilic acid-etched surface. Put the pure titanium substrate into a constant temperature resistance box, set the temperature at 50°C, and keep it warm for 5 minutes, and confirm that the surface of the substrate is completely dry. Press the spray pump so that the DCPA solution is evenly sprayed on the titanium substrate. Since the substrate is super-hydrophilic, the DCPA solution can spread evenly on its surface. A...

Embodiment 2

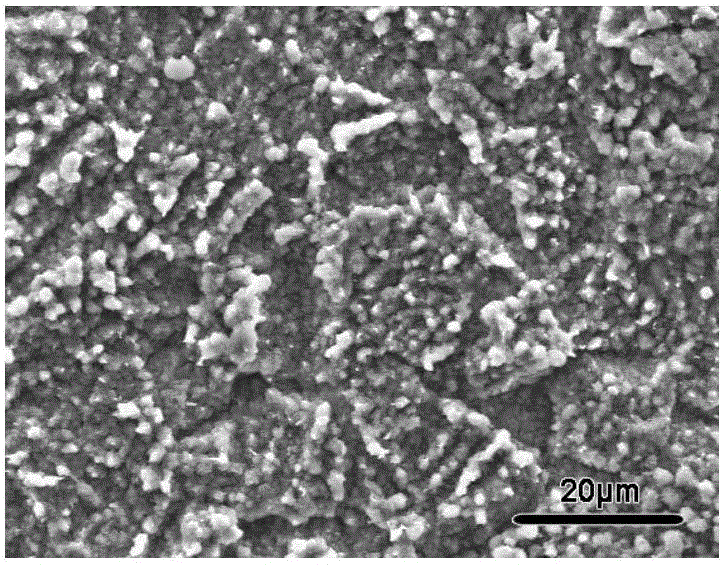

[0024] The steps are basically the same as in Example 1, except that the ratio of the spraying solution this time is: 25g of analytically pure DCPA, 80ml of deionized water, and 20mL of dilute hydrochloric acid HCl with a concentration of 0.20mol / L. The number of times of spray drying is 30 times, and the drying temperature is 60°C. SEM( Figure 4 ), XRD ( Figure 5 ) analysis results show that the DCPA coating prepared by this method is uniform and complete, and can completely cover the titanium substrate.

Embodiment 3

[0026] The steps are basically the same as in Example 1, except that the ratio of the spraying solution this time is: 10g of analytically pure DCPA, 92ml of deionized water, and 8mL of dilute hydrochloric acid HCl with a concentration of 0.08mol / L. The number of times of spray drying is 60 times, and the drying temperature is 70°C. SEM( Figure 6 ), XRD ( Figure 7 ) analysis results show that the DCPA coating prepared by this method is uniform, complete and dense, and can completely cover the titanium substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com