Method and device for removing mercury from ammonia desulfurization slurry

An ammonia desulfurization and mercury removal technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as inability to achieve mercury removal, increase sewage treatment costs, inhibit re-release, and the method is simple and easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

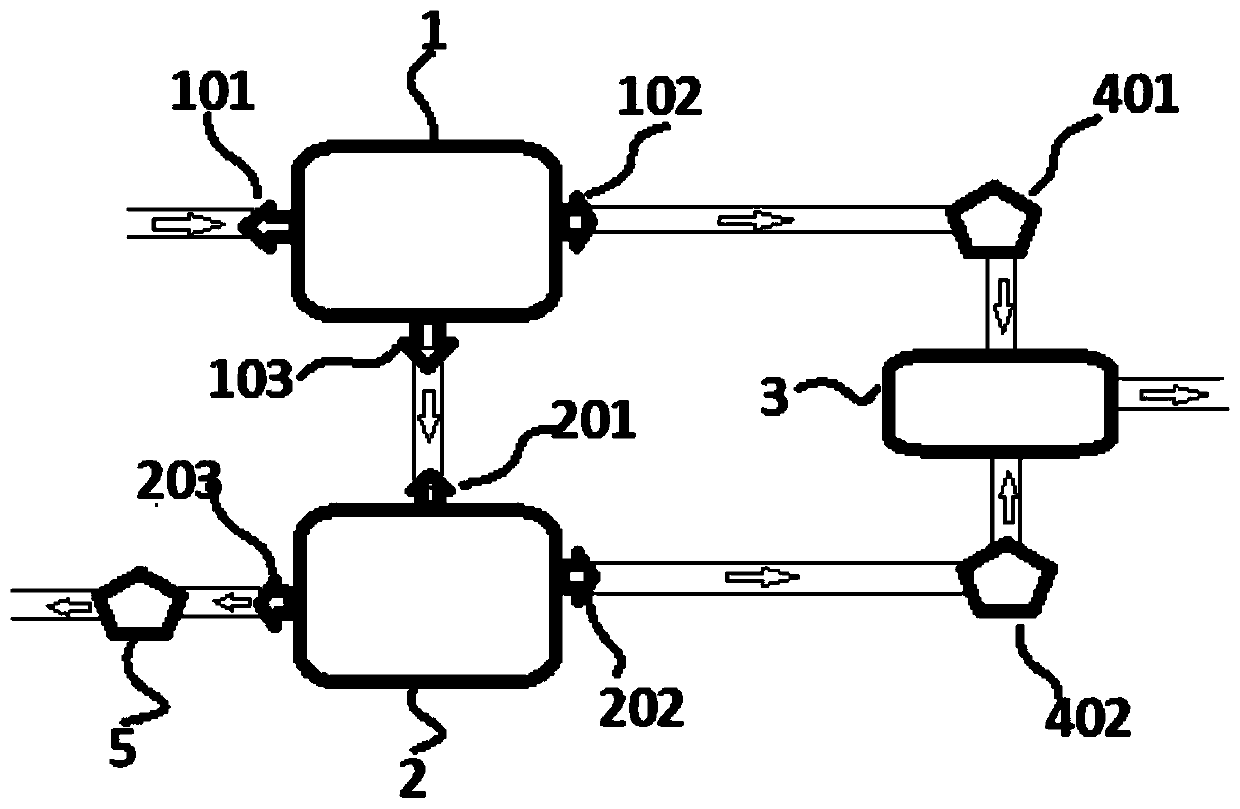

Image

Examples

Embodiment 1

[0054] The process of obtaining the ammonia desulfurization slurry in this embodiment is as follows: using an improved selective catalytic reduction (SCR) catalyst containing metal oxides such as vanadium, tungsten, and titanium, which can catalyze the oxidation of elemental mercury, and the oxidation efficiency is greater than 85%. The oxidized divalent mercury enters the rear ammonia desulfurization absorption tower with the flue gas, and after being fully absorbed by the desulfurization circulating fluid, the divalent mercury in the flue gas enters the ammonia desulfurization slurry.

[0055] The ammoniacal desulfurization slurry in this embodiment is ammonium sulfate slurry with a mass fraction of 1%, and the concentration of divalent mercury in the ammoniacal ammonium sulfate slurry is 50 μg / L.

[0056] A mercury removal agent is added into the ammonium sulfate slurry, the mercury removal agent is composed of ammonium sulfide, the reaction temperature is 45-55° C., and the...

Embodiment 2

[0062] The process of obtaining the ammonia desulfurization slurry in this embodiment is as follows: using an improved selective catalytic reduction (SCR) catalyst containing metal oxides such as vanadium, tungsten, and titanium, which can catalyze the oxidation of elemental mercury, and the oxidation efficiency is greater than 90%. The oxidized divalent mercury enters the rear ammonia desulfurization absorption tower with the flue gas, and after being fully absorbed by the desulfurization circulating fluid, the divalent mercury in the flue gas enters the ammonia desulfurization slurry.

[0063] The ammonia desulfurization slurry in this embodiment is ammonium sulfate slurry with a mass fraction of 1%. The concentration of divalent mercury in the ammonium sulfate slurry is 150 μg / L. A mercury removal agent is added to the ammonium sulfate slurry. The mercury removal agent is composed of: sulfur Ammonium sulfosulfate, the reaction temperature is 46-55°C, and the pH of the reacti...

Embodiment 3

[0068] The process of obtaining the ammonia desulfurization slurry in this embodiment is as follows: using an improved selective catalytic reduction (SCR) catalyst containing metal oxides such as vanadium, tungsten, and titanium, which can catalyze the oxidation of elemental mercury, and the oxidation efficiency is greater than 90%. The oxidized divalent mercury enters the rear ammonia desulfurization absorption tower with the flue gas, and after being fully absorbed by the desulfurization circulating fluid, the divalent mercury in the flue gas enters the ammonia desulfurization slurry.

[0069] The ammonia desulfurization slurry in this embodiment is ammonium sulfate slurry with a mass fraction of 2%. The concentration of divalent mercury in the ammonium sulfate slurry is 500 μg / L. A mercury removal agent is added to the ammonium sulfate slurry. The mercury removal agent is composed of: A mixture of ammonium and ammonium thiosulfate, the reaction temperature is 50-55°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com