A preparation method of hydrophilic high-capacity ion exchange separation and purification microsphere material

An ion exchange and hydrophilic technology, which is applied in the field of preparation of hydrophilic high-capacity ion exchange separation and purification microsphere materials, can solve the problems of low separation efficiency and insufficient exchange capacity, and achieve high separation efficiency and high separation capacity. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

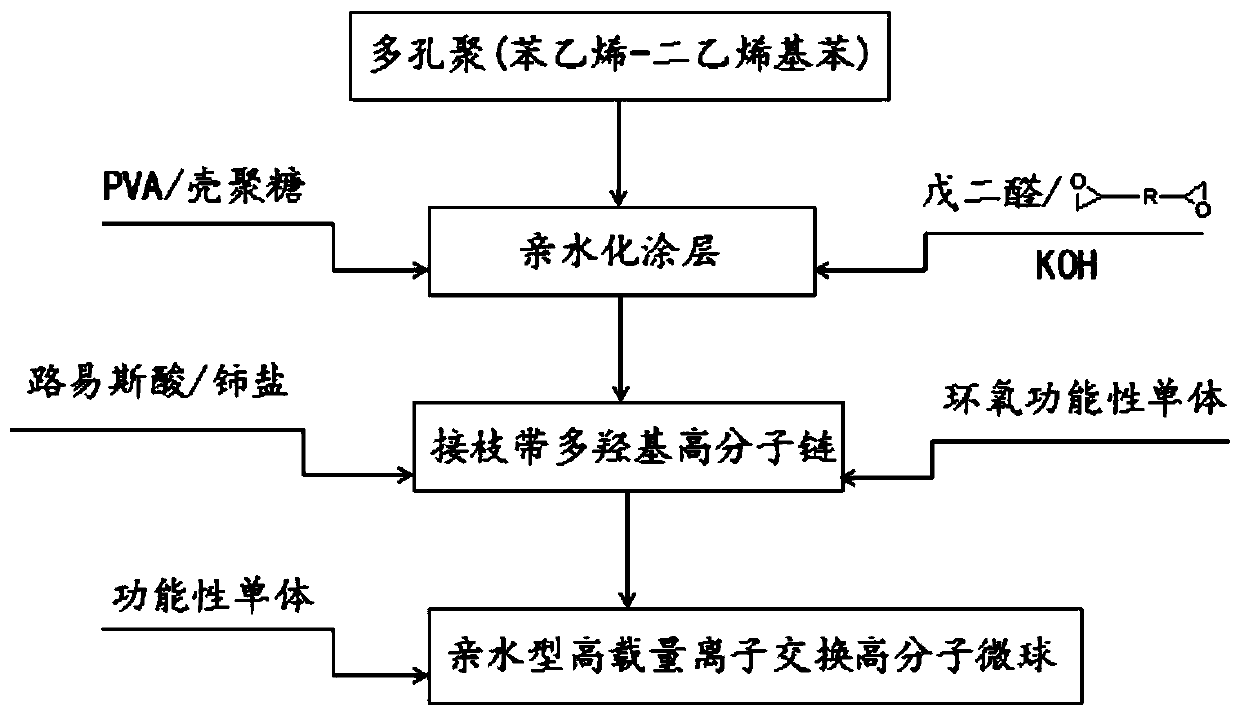

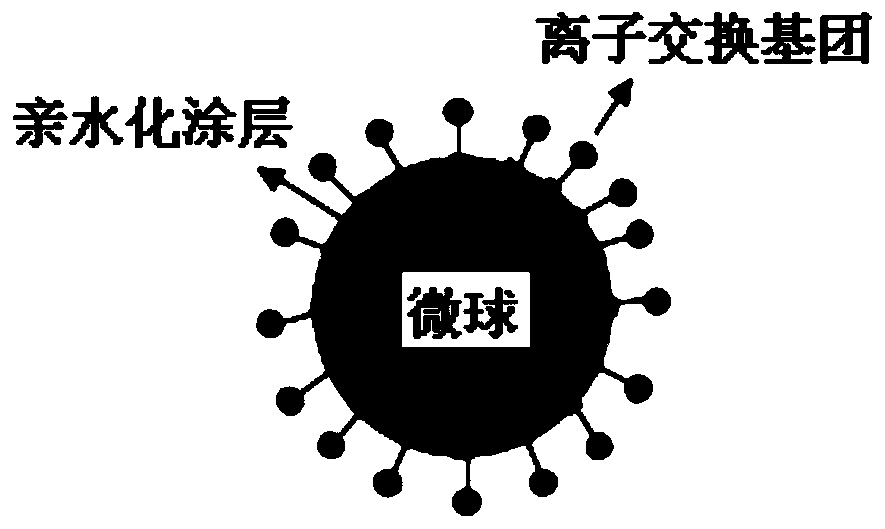

[0033] Such as figure 1 As shown, a method for preparing a hydrophilic high-capacity ion-exchange separation and purification microsphere material according to an embodiment of the present invention includes: (1) conducting poly(styrene-divinylbenzene) microspheres with a porous structure The hydrophilic coating is modified to obtain poly(styrene-divinylbenzene) microspheres modified by the hydrophilic coating, which have no non-specific adsorption capacity for proteins and polypeptide molecules; (2) the hydrophilic coating Coating-modified poly(styrene-divinylbenzene) microspheres are dispersed in dioxane, and catalysts and epoxy functional monomers are added to react to obtain poly(styrene-divinylbenzene) polymer chains with polyhydroxyl structures. (ethylene-divinylbenzene) microspheres; and (3) dispersing poly(styrene-divinylbenzene) microspheres with polyhydroxyl structure macromolecular chains in water or dioxane, adding ion exchange function React monomers to obtain hy...

Embodiment 1

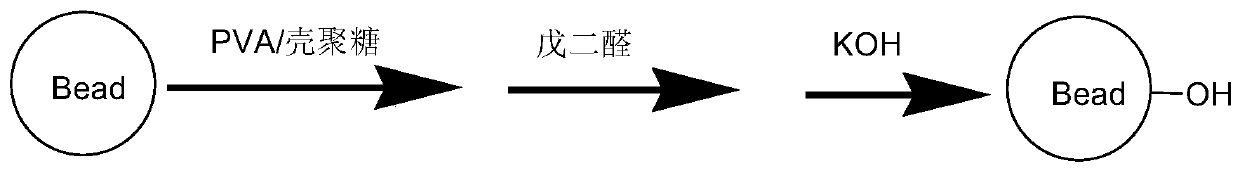

[0042] Such as figure 2 As shown, the preparation method of the ion-exchange separation and purification microsphere material of the present embodiment includes the following steps, the preparation of poly(styrene-divinylbenzene) microsphere hydrophilic coating, specifically:

[0043] 1. Take 10g of poly(styrene-divinylbenzene) microspheres with a particle size of 30μm and disperse them in 100mL of dioxane / water (volume ratio 1:1). After ultrasonic stirring to make them uniformly dispersed, add 10g of polyethylene Alcohol solution, stirred at room temperature for 3-5h.

[0044] 2. After the reaction is complete, filter with a sand core funnel of the corresponding specification, wash with water, and dry at a constant temperature of 60°C to constant weight after cleaning.

[0045] 3. Take 10g of the dried microspheres and disperse them in 100mL of water. After ultrasonic stirring to make them evenly dispersed, add 0.5g of glutaraldehyde and 10mL of 4mol / L KOH solution. After t...

Embodiment 2

[0047] Such as figure 2 As shown, the preparation method of the ion-exchange separation and purification microsphere material of the present embodiment includes the following steps, the preparation of poly(styrene-divinylbenzene) microsphere hydrophilic coating, specifically:

[0048] 1. Take 15g of poly(styrene-divinylbenzene) microspheres with a particle size of 30μm and disperse them in 150mL of dioxane / water (volume ratio 1:1). Sugar solution, stirred at room temperature for 3-5h.

[0049] 2. After the reaction is complete, filter with a sand core funnel of the corresponding specification, wash with water, and dry at a constant temperature of 60°C to constant weight after cleaning.

[0050] 3. Take 15g of the dried microspheres and disperse them in 150mL of water. After ultrasonic stirring to make them evenly dispersed, add 0.75g of glutaraldehyde and 10mL of 4mol / L KOH solution. After the reaction is complete, use a sand core funnel of the corresponding specification F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com