Preparation method and application of silicon dioxide surface modified by cyclic choline phosphate polymer

A technology of phosphorylcholine and silicon dioxide, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as low efficiency, patient suffering, and reduced detection sensitivity, and achieve good stability, good stability, and anti-pollution. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Silica surface treatment:

[0035] Place the purchased silicon dioxide chip of the surface plasmon resonance sensor (SPR) in an ultraviolet ozone cleaner, take it out after being irradiated with ultraviolet light for 30 minutes, wash it three times with ethanol and water in sequence, and dry it with nitrogen gas for later use.

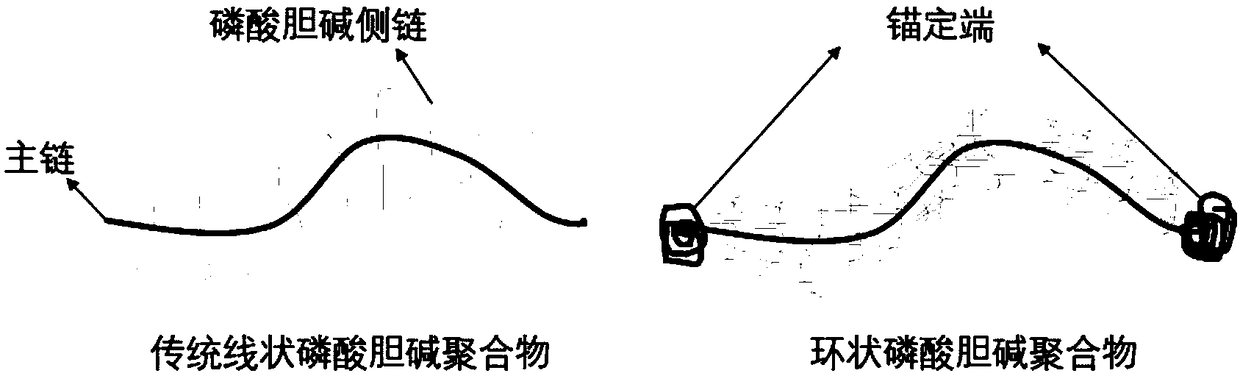

[0036] 2) Synthesis of cyclic phosphorylcholine polymer:

[0037] Step 1: Take a 25mL reaction bottle and add 0.057mmol copper chloride, 0.718mmol 4,4'-dinonyl-2,2'-bipyridyl, 115mmol 2-(trimethylsilyloxy)ethyl methyl Acrylic acid salt, 4.1mL anisole and 115mmol methyl methacrylate, with 0.0718mmol dibromoisobutyrate as the initiator, after degassing and deoxygenation, 0.287mmol cuprous chloride was added under nitrogen protection conditions to react , to prepare synthetic molecule A;

[0038] In the second step, take 0.0081mmol synthetic molecule A and 4.0μmol chloride, 0.0808mmol 4,4'-dinonyl-2,2'-bipyridyl, 12.9mmol dimethylaminoethyl me...

Embodiment 2

[0052] 1) Silica chip processing:

[0053] Place the purchased silicon dioxide chip adapted to the crystal microbalance (QCM-D) in an ultraviolet ozone cleaner, take it out after being irradiated with ultraviolet light for 30 minutes, wash it three times with ethanol and water in sequence, and dry it with nitrogen gas for later use.

[0054] 2) Synthesis of cyclic phosphorylcholine polymer: the method is the same as in Example 1.

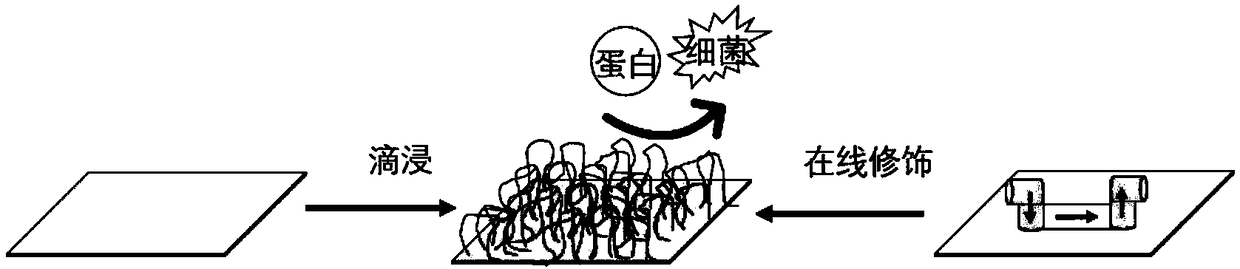

[0055] 3) Cyclic phosphorylcholine polymer modification on the surface of silica:

[0056] Method 1: 1 mg of the polymer obtained in 2) was dissolved in 10 mL of deionized water to a final concentration of 0.1 mg / mL. Then take 500 μL of the above solution and drop it on the surface of the silicon dioxide chip obtained in 1), to ensure that the solution completely covers the chip surface, and adsorb for 0.5 h at room temperature. After the reaction, the surface of the silicon dioxide was washed three times with absolute ethanol and water successive...

Embodiment 3

[0062] 1) Prism processing:

[0063] Place the purchased prism in an ultraviolet ozone cleaner, take it out after 30 minutes of ultraviolet light irradiation, wash it three times with ethanol and water successively, and dry it with nitrogen gas for later use.

[0064] 2) Synthesis of cyclic phosphorylcholine polymer: the method is the same as in Example 1.

[0065] 3) Cyclic phosphorylcholine polymer modification on the surface of the prism:

[0066] 1 mg of the polymer obtained in step 2) was dissolved in 10 mL of deionized water to a final concentration of 0.1 mg / mL. Then take 500 μL of the above solution and drop it on the clean prism surface obtained in step 1), ensure that the solution completely covers the prism surface, and adsorb for 0.5 h at room temperature. After the reaction, the surface of the prism was washed three times with absolute ethanol and water successively, and dried with nitrogen gas to obtain a prism modified based on the cyclic phosphorylcholine pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com