Stepping type casting wax extrusion device

An extrusion device, a step-by-step technology, applied in the field of step-by-step casting wax extrusion devices, can solve the problems of air entering the wax mold, etc., and achieve the effect of no air bubbles, simple structure, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

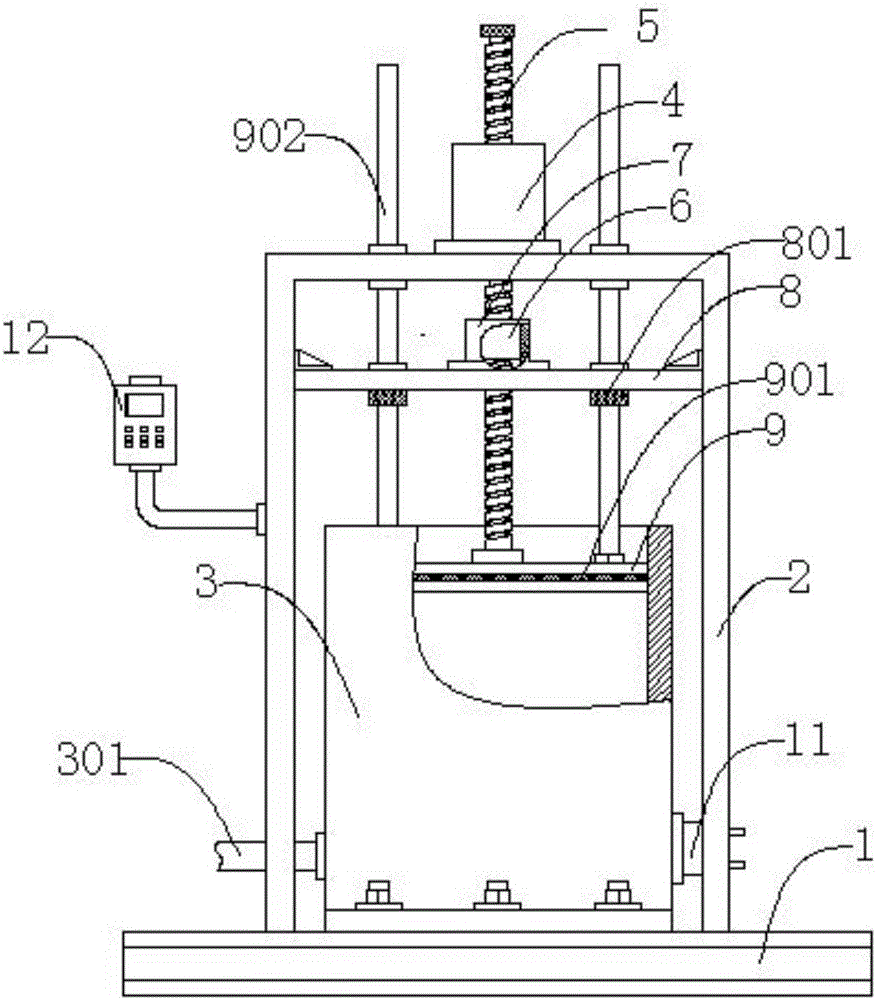

[0021] Such as figure 1 As shown, a step-by-step casting wax extrusion device includes a channel steel base 1, a door frame 2, a storage barrel 3, a linear stepping motor 4, a lead screw 5, a feed nut 6, a fixed sleeve 7, Fixed plate 8, piston 9, heating tube 10, thermocouple 11, controller 12, described portal frame 2 is positioned at the upper end of channel steel base 1, and described portal frame 2 is threadedly connected with channel steel base 1, and described The storage tank 3 is located inside the door frame 2 and at the upper end of the channel steel base 1, the storage tank 3 is movably connected with the door frame 2 and connected with the channel steel base 1, and the linear stepping motor 4 Located at the upper end of the door frame 2, the linear stepper motor 4 is threadedly connected with the door frame 2, the lead screw 5 runs through the linear stepper motor 4 and the door frame 2, and the lead screw 5 and the linear stepper motor 4 are meshed and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com