Temperature-controlled water-cooled thin-walled round tube cladding equipment

A cladding and cold technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of difficult control of the surface temperature of thin-walled circular tubes, affecting the quality of cladding, and short service life, achieving real-time and effective control effects , The effect of various and flexible welding methods, timely and effective maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

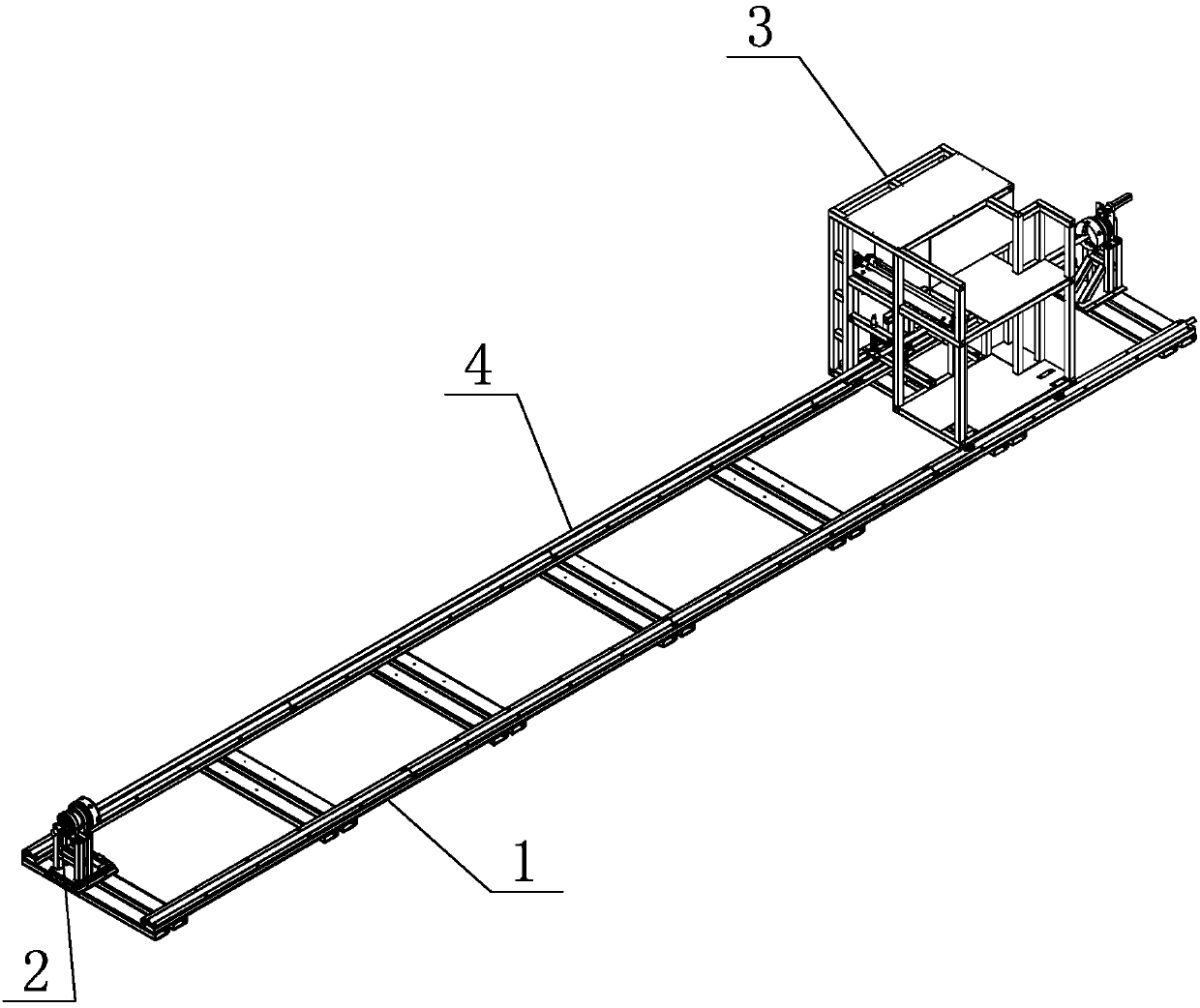

[0023] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Describe this embodiment. This embodiment includes a track assembly 1, two temperature-controlled rotary water supply assemblies 2 and a fully automatic welding vehicle 3. The track assembly 1 includes an active rotary joint, a driven rotary joint and a walking track. The active rotary joint and the driven rotary joint are respectively arranged at both ends of the walking track, the fully automatic welding vehicle 3 is set on the walking track and it reciprocates along the length direction of the walking track, and one end of the processing tube 4 is set on the driven rotating track. On the joint, the other end of the processing pipe 4 passes through the automatic welding car 3 and is connected to the active rotary joint, and a temperature-controlling rotary water supply assembly 2 is respectively provided at both ends of the processing pipe 4;

[0024] Ea...

specific Embodiment approach 2

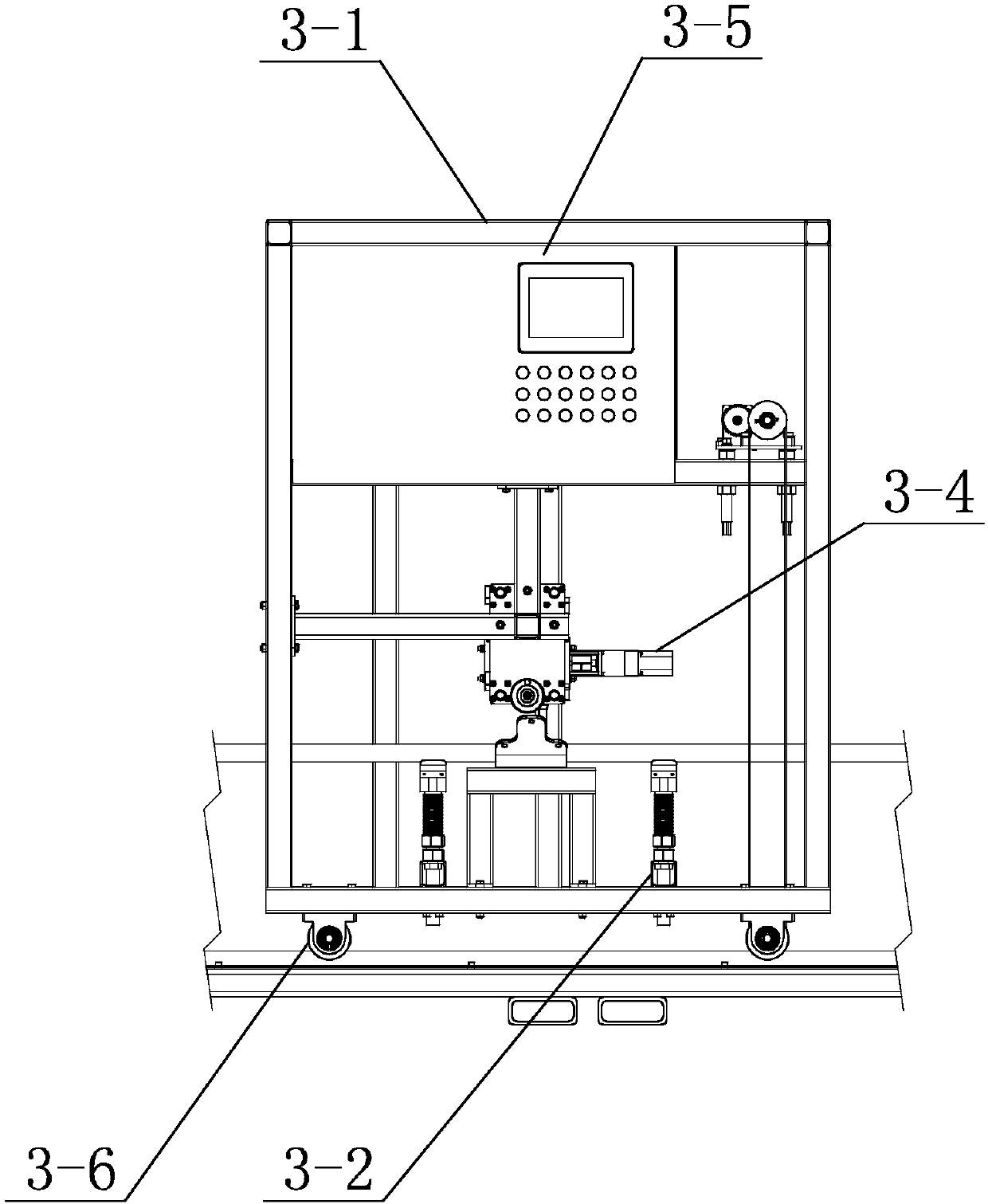

[0029] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Image 6Describe this embodiment. In this embodiment, the fully automatic welding vehicle 3 includes a frame body 3-1, a position control assembly 3-2, a linear oscillator 3-4, a control system 3-5, a workbench 3-8, a welding Application gun 3-9, at least one drive assembly and multiple mobile single wheels 3-6, the bottom of the frame body 3-1 is provided with multiple mobile single wheels 3-6, at least one drive assembly is arranged on the frame body 3-1, the workbench 3-8 is set inside the frame body 3-1, the linear oscillator 3-4 is set directly above the workbench 3-8, and the linear oscillator 3-4 is set There is a cladding gun 3-9, the tip of the cladding gun 3-9 is set facing the workbench 3-8, the control unit 3-2 is set around the workbench 3-8, and the control system 3-5 is set on the frame body 3-1 and it is electrically connected with at least one drive assembly. Other un...

specific Embodiment approach 3

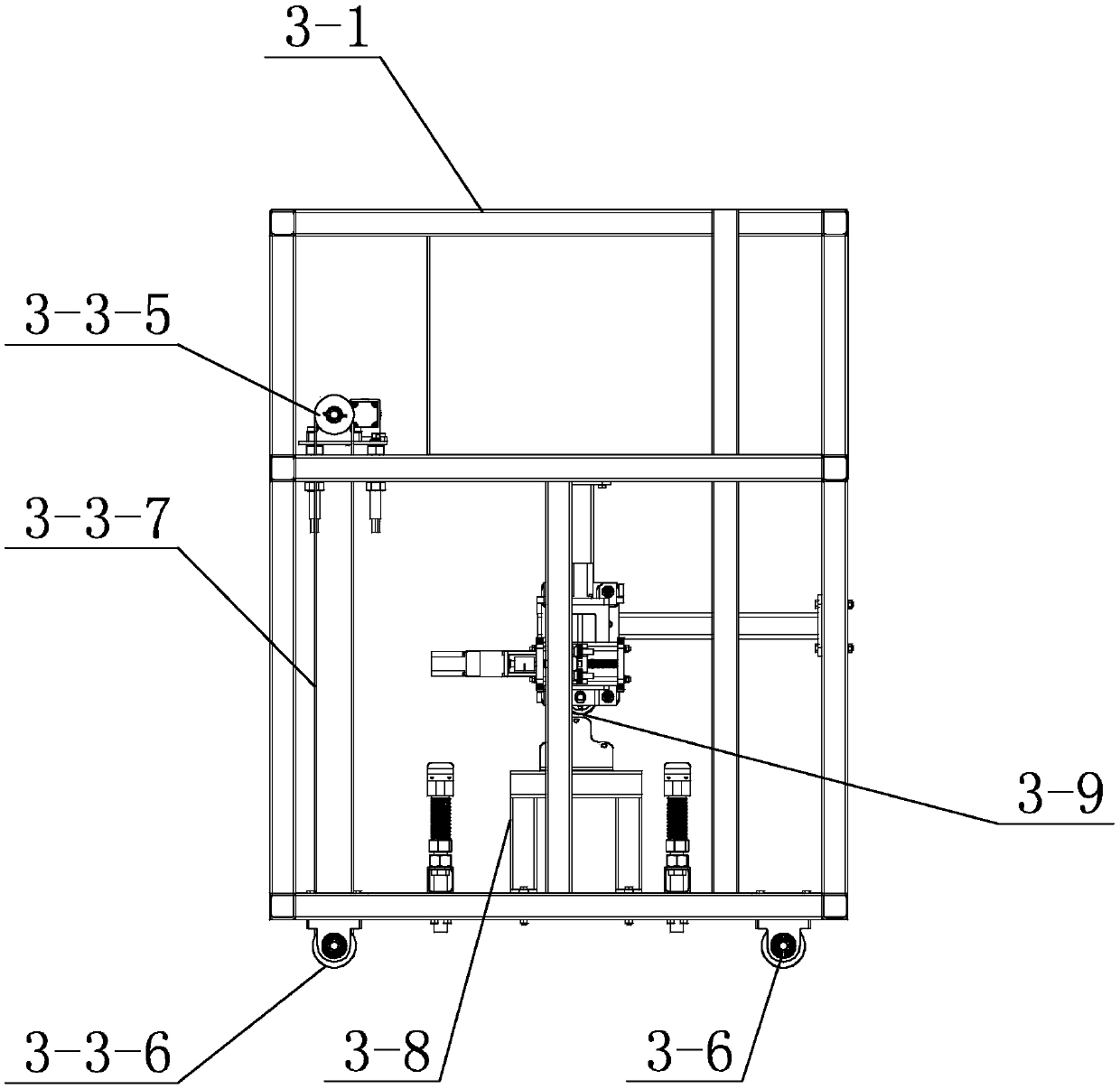

[0030] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Image 6 Describe this embodiment. In this embodiment, the drive assembly includes a rotating shaft 3-3-1, a driving gear 3-3-2, a driven gear 3-3-3, a motor 3-3-4, two upper runners 3- 3-5, two lower runners 3-3-6 and two conveyor belts 3-3-7, the motor 3-3-4 is set on the top of the frame body 3-1, the two lower runners 3- 3-6 are respectively arranged on both sides of the bottom of the frame body 3-1, the output shaft of the motor 3-3-4 is set with a driving gear 3-3-2, and the rotating shaft 3-3-1 is set with a driven gear The gear 3-3-3, the driving gear 3-3-2 is meshed with the driven gear 3-3-3, and the two ends of the rotating shaft 3-3-1 are each equipped with an upper runner 3-3-5, Each upper runner 3-3-5 is correspondingly provided with a conveyor belt 3-3-7, and each upper runner 3-3-5 corresponds to a lower runner 3-3-6, and each upper runner 3 -3-5 is connected with it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com