Mixed flow water turbine blade machining device

A processing device and water turbine technology, applied in metal processing equipment, reaction engines, mechanical equipment, etc., can solve the problems of high production cost, high difficulty of finishing, and inconvenience, so as to improve processing efficiency, reduce labor cost, and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

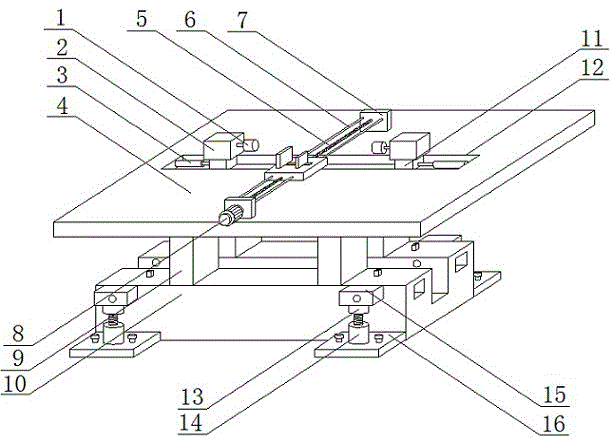

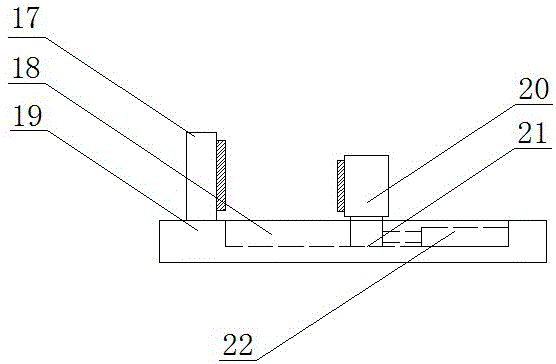

[0014] refer to Figure 1-2 , a Francis turbine blade processing device, comprising a base 10, which acts as a bearing, the upper end of the base 10 is fixed with a plurality of supporting blocks 9, the upper end of the supporting blocks 9 is fixed with a bearing plate 4, and the upper end of the supporting plate 4 is provided with a first The chute 12, the first cylinder 3 is fixed on the side walls at both ends of the first chute 12, and two first sliders 11 are installed in the first chute 12, and the first slider 11 passes through the first cylinder 3 The piston rod telescopically slides in the first chute 12, the end of the piston rod of the first cylinder 3 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap