A kind of dot-matrix technology 3D printing method and equipment applying it

A technology of 3D printing and lattice technology, applied in the field of 3D printing, can solve the problem of limited photoreaction polymerization, thermal polymerization, cold polymerization, cationic polymerization, anionic polymerization, metal reduction synthesis, self-assembly, semiconductor materials Synthesis, synthesis of inorganic materials and other issues, to achieve the effect of fine printing and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A dot matrix technology 3D printing method, the method is a continuous liquid interface synthesis method, the method triggers a solidification liquid in the form of a dot matrix to generate a curing reaction for printing.

Embodiment 2

[0075] The only difference from Example 1 is that the method triggers the curing reaction of the partial curing liquid in the form of dot matrix for printing.

[0076] Further, the method utilizes a lattice reaction device.

[0077] Furthermore, the dot matrix reaction device includes a dot matrix plate, and the dot matrix reaction initiating points are arranged on the dot matrix plate.

[0078] Furthermore, the solidification liquid at the initiation point of the lattice reaction is initiated by an electronic control device to undergo a solidification reaction.

[0079] Furthermore, the electronic control device controls the reaction conditions at the initiation point of the lattice reaction to initiate the curing reaction.

[0080] Furthermore, the ways to control the reaction conditions include electric current, heating or cooling.

[0081] Furthermore, the lattice reaction initiating point has a shape.

[0082] Furthermore, each initiation point of the lattice reaction ...

Embodiment 3

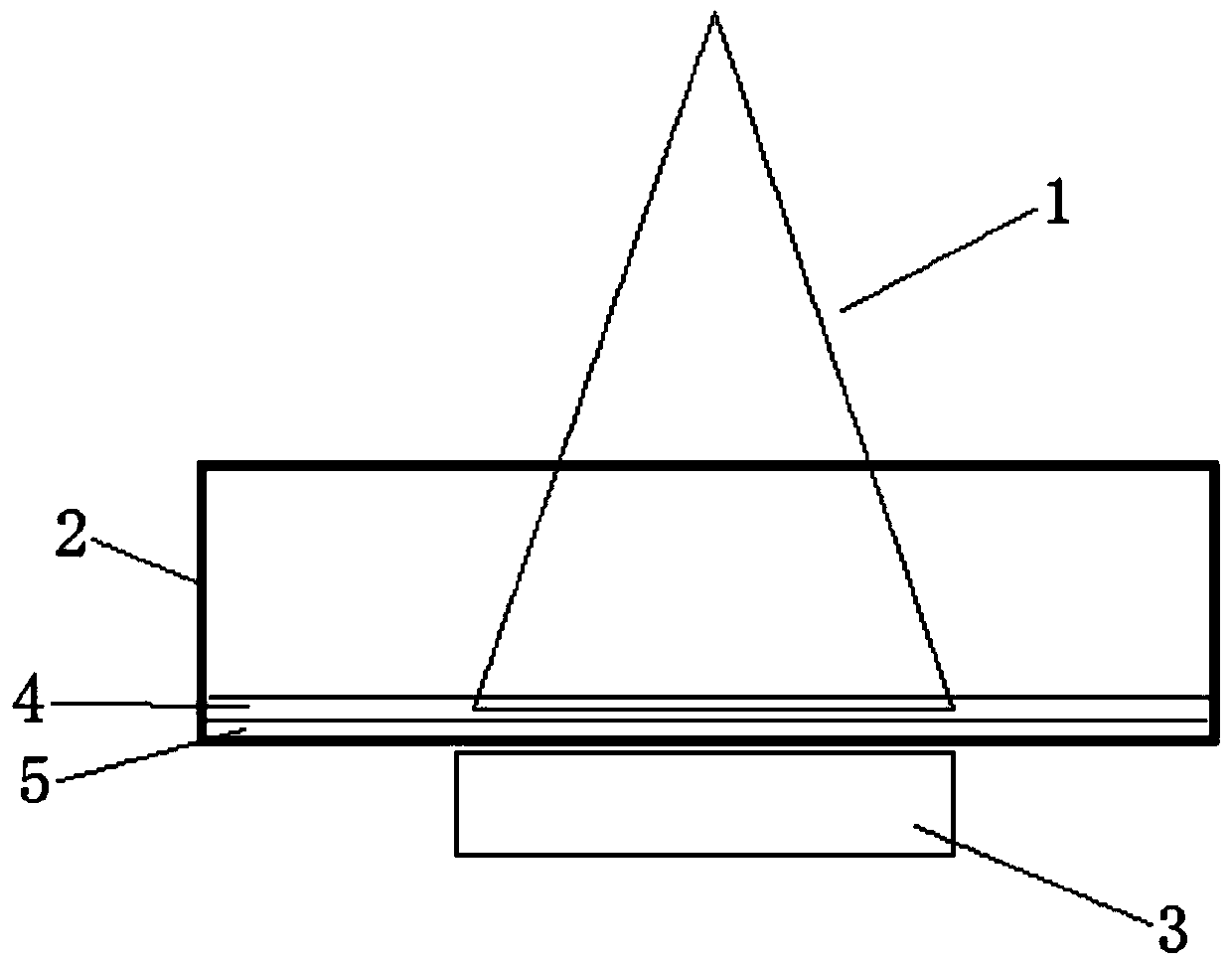

[0102] like figure 1 and 2 As shown, a device applying the 3D printing method of the dot matrix technology includes a support 1 , a solidification liquid pool 2 , and a dot matrix reaction device 3 .

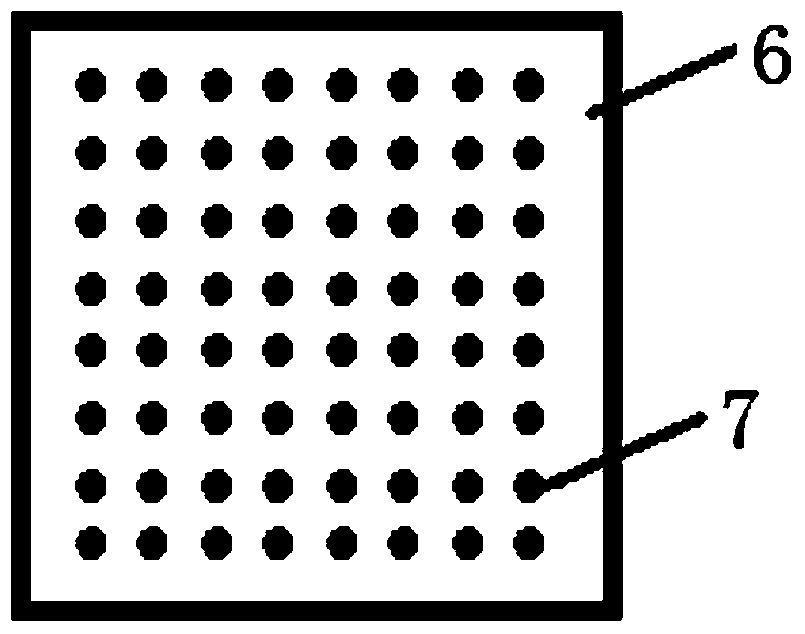

[0103] Furthermore, the dot matrix reaction device includes a dot matrix plate 6 on which a dot matrix reaction initiating point 7 is set.

[0104] Furthermore, the solidified liquid at the point 7 of the lattice reaction initiation point 7 is initiated by an electronic control device to undergo a solidification reaction.

[0105] Furthermore, the electronic control device controls the reaction conditions at the lattice reaction initiation point 7 to initiate the curing reaction.

[0106] Furthermore, the ways to control the reaction conditions include electric current, heating or cooling.

[0107] Furthermore, each of the lattice reaction initiation points 7 is controlled by a separate electronic control device.

[0108] Furthermore, the lattice reaction initiation point 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com