3D printing nozzle based on ultrasonic micro forging and printing method

A 3D printing and printing head technology, applied in the field of additive manufacturing, can solve the problems of low surface activity of fiber-reinforced phase materials, weak strength of FDM molded parts, and reduced quality of printed parts, so as to improve the quality and accuracy of printing surfaces and improve the melting point. Bulk viscosity and fluidity, the effect of improving print bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

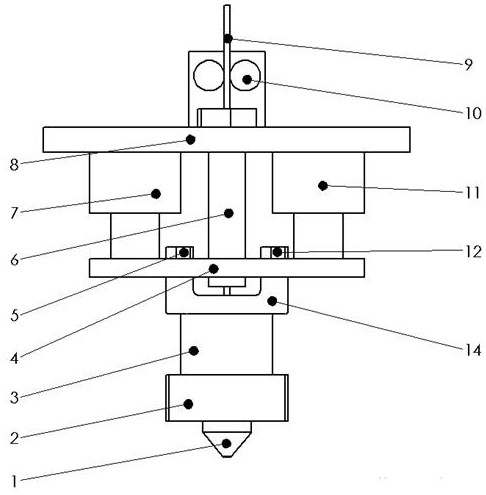

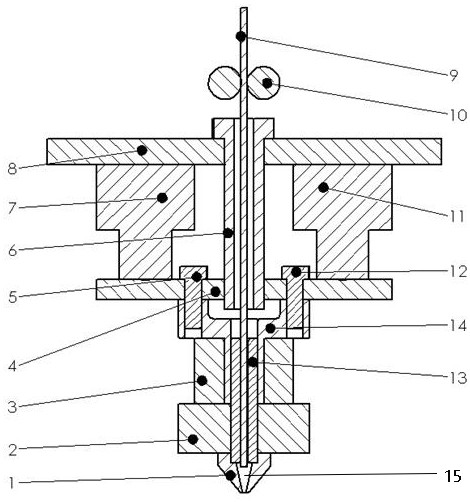

[0031] A 3D printing nozzle based on ultrasonic micro-forging, including a printing head 1 with a melting cavity 15 inside, the upper part of the printing head 1 is connected to the lower end of the melting throat 13 by threads, and the outer part of the lower end of the melting throat 13 is connected to the printing heat source 2 by interference Fitting connection, the upper end of the melting throat 13 is connected to the cooling device 3, the top of the melting throat 13 is connected with the middle hole at the bottom of the adapter bracket 14 with an interference fit, the top of the adapter bracket 14 is connected with the connecting plate 4, and the middle hole of the connecting plate 4 and The lower end of the threaded pipe 6 is connected, and the upper end of the threaded pipe 6 is connected to the two-dimensional module connecting frame 8, and the first ultrasonic vibration transducer 7 and the second ultrasonic vibration transducer are connected between the two-dimensio...

Embodiment 2

[0038]A method for printing a 3D printing nozzle based on ultrasonic micro-forging, comprising the following steps:

[0039] The first step is to install the 3D printing nozzle based on ultrasonic micro-forging on the 3D printer, first turn on the cooling device 3 and the printing heat source 2 in sequence, and wait until the temperature of the melting throat 13, the printing head 1 and the melting chamber 15 reach the set working melting temperature After the temperature is reached, the wire material 9 is transported into the melting cavity 15 inside the print head 1 through the wire feeder 10, and then the first ultrasonic vibration transducer 7 and the second ultrasonic vibration transducer 11 are turned on, and the high-frequency vibration force field It is transmitted to the print head 1 and the melting cavity 15 through the connecting plate 4, the threaded pipe 6, the adapter bracket 14, and the melting throat 13 in turn. The printer control system controls the two-dimens...

Embodiment 3

[0045] Such as figure 1 and figure 2 As shown, a 3D printing nozzle based on ultrasonic micro-forging includes a printing head 1 with a melting cavity 15 inside. Relying on the interference fit connection, the upper end of the melting throat 13 is connected to the cooling device 3 outside, the top of the melting throat 13 is connected to the middle hole at the bottom of the adapter bracket 14 with an interference fit, and the top of the adapter bracket 14 is connected to the connecting plate 4 through the first screw 5 1. The second screw 12 is connected, the middle hole of the connecting plate 4 is connected with the lower end of the threaded pipe 6, the outer part of the upper end of the threaded pipe 6 is connected with the two-dimensional module connecting frame 8, and the first ultrasonic wave is connected between the two-dimensional module connecting frame 8 and the connecting plate 4. The vibration transducer 7 and the second ultrasonic vibration transducer 11, a wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com