Anti-explosion porous concrete with negative poisson's ratio effect and preparation method thereof

A technology of porous concrete and negative Poisson's ratio, which is applied in the fields of porous concrete and its preparation, explosion-proof functional porous concrete and its preparation, to achieve the effects of improving absorption capacity, avoiding secondary damage, improving resistance and absorbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

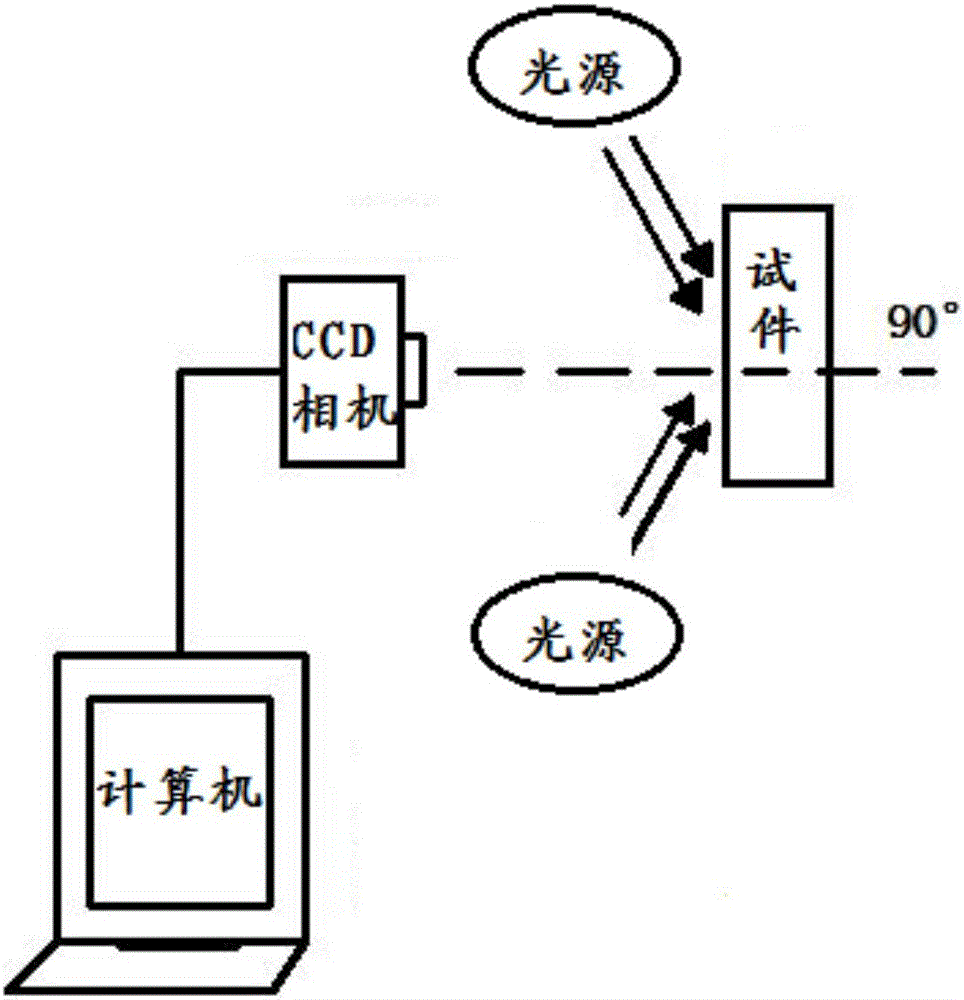

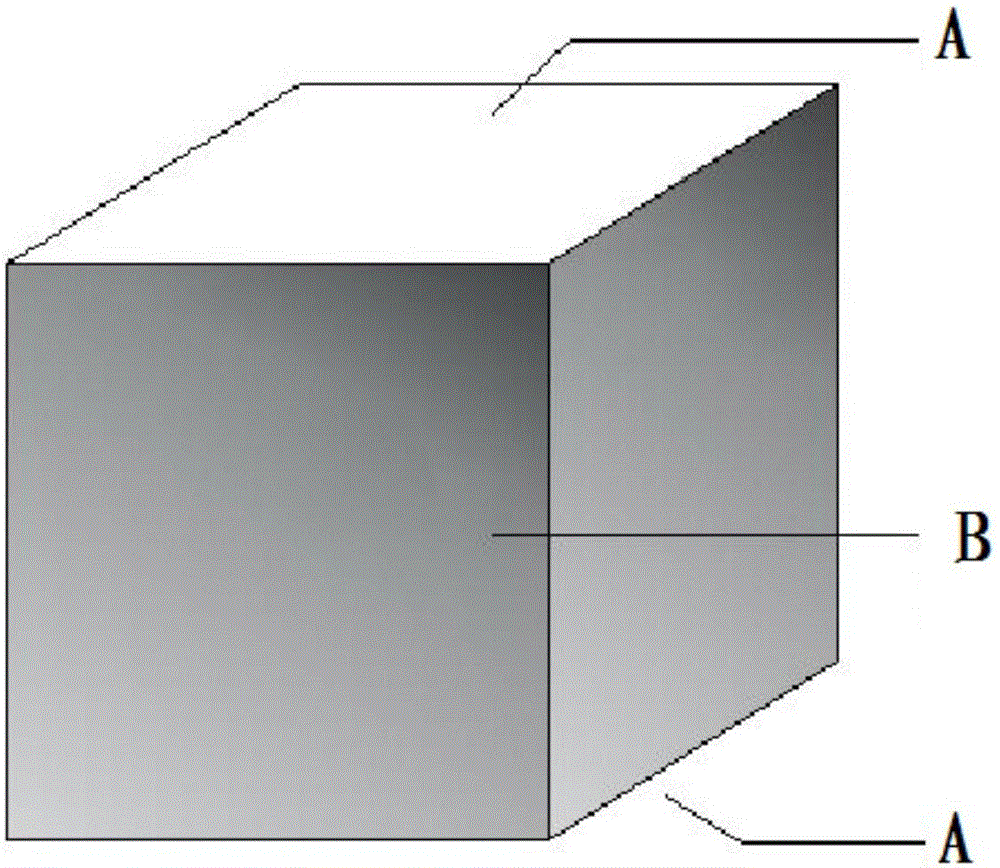

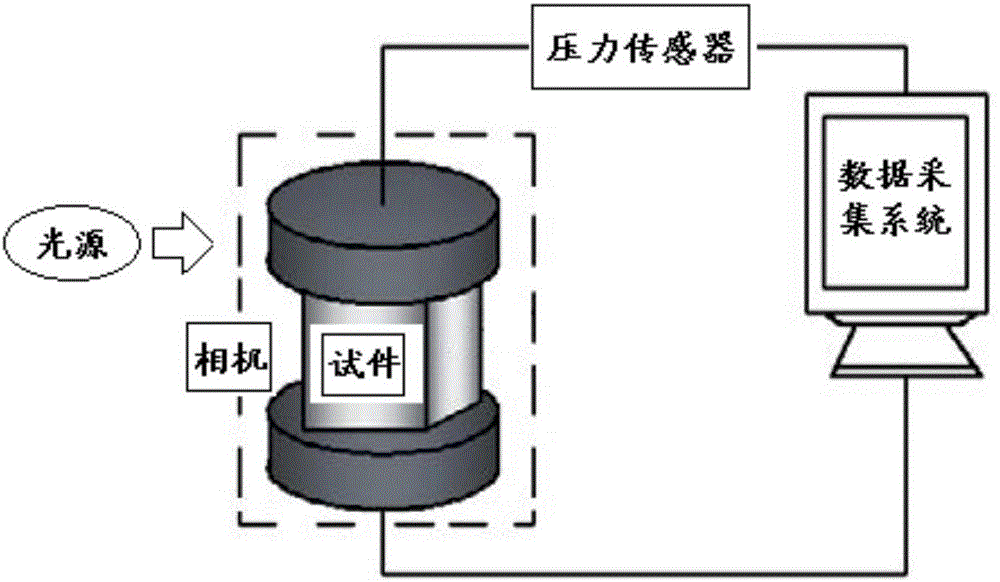

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Explosion-proof porous concrete with interconnected hole structure

[0035] Explosion-proof porous concrete with negative Poisson's ratio effect, the explosion-proof porous concrete has a connected hole structure. The explosion-proof porous concrete is prepared from the following components: gelling material, water reducer, activator, foam stabilizer and foaming agent. Wherein, the gelling material is Portland cement, the foaming agent is hydrogen peroxide, the foam stabilizer is carboxymethyl cellulose, and the activator is KMnO with a mass fraction of 0.3%. 4 solution, and the water reducer is a polycarboxylate water reducer. In parts by weight, the gelling material is 300g, hydrogen peroxide is 30g, carboxymethyl cellulose is 35g, and the mass fraction is 0.3% KMnO 4 The solution is 0.8g, and the polycarboxylate water reducer is 0.6g.

[0036] The preparation method of the explosion-proof porous concrete with negative Poisson's ratio effect comprises th...

Embodiment 2

[0050] Embodiment 2: Explosion-proof porous concrete with connected hole structure

[0051] Different from Example 1, the gelling material is gypsum, and the foam stabilizer is calcium stearate. In parts by weight, the gelling material is 280g, hydrogen peroxide is 25g, and calcium stearate is 29g; the mass fraction is 0.5% KMnO 4 The solution is 0.5g, and the polycarboxylate water reducer is 0.5g.

[0052] The preparation method of explosion-proof porous concrete with negative Poisson's ratio effect, the rotating speed of low-speed stirring is 70r / min, and the rotating speed of high-speed stirring is 250r / min; the weight ratio of water and cementitious material in step (1) is 0.6:1.

[0053] Calculated according to the test results, the Poisson's ratio of the explosion-proof porous concrete with interconnected pore structure prepared in this embodiment is -0.36.

Embodiment 3

[0054] Example 3: Explosion-proof porous concrete with connected hole structure

[0055] The difference from Example 1 is that the gelling material is expansive cement and the foam stabilizer is sodium cellulose. In parts by weight, the gelling material is 320g; hydrogen peroxide is 41g, sodium cellulose is 52g, and the mass fraction is 0.6% KMnO 4 The solution is 1 g, and the polycarboxylate water reducer is 0.7 g.

[0056] In the preparation method of explosion-proof porous concrete with negative Poisson's ratio effect, the rotating speed of low-speed stirring is 30r / min, and the rotating speed of high-speed stirring is 350r / min; the weight ratio of water and cementitious material in step (1) is 0.55:1.

[0057] Calculated according to the test results, the Poisson's ratio of the explosion-proof porous concrete with interconnected pore structure prepared in this embodiment is -0.82.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com