3D (three-dimensional) printing powder and preparation method thereof

A 3D printing and powder technology, applied in the direction of additive processing, etc., can solve the problems of looseness, poor flexibility, easy to change color, etc., and achieve the effect of simple method, not easy to change color, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

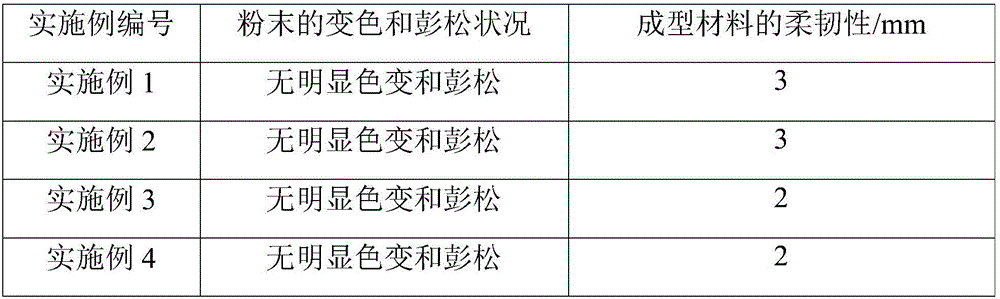

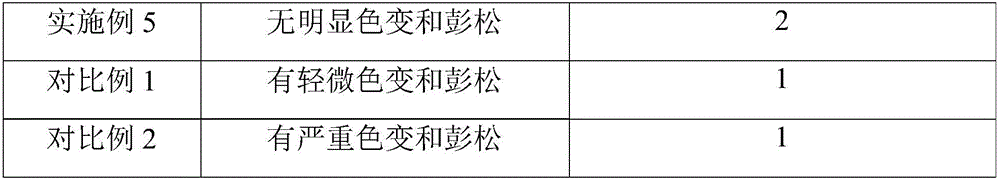

Examples

preparation example Construction

[0012] The invention provides a preparation method of 3D printing powder, the preparation method comprising: (1) polyvinyl alcohol, methyl methacrylate, butyl acrylate, β-hydroxyethyl methacrylate, initiator and mixed with water, filtered after heating and reacting, to obtain a hydroxyacrylic acid copolymer resin; (2) drying and grinding the hydroxyacrylic acid copolymer resin to obtain the 3D printing powder; wherein, relative to 100 parts by weight of polyvinyl alcohol, the The consumption of methyl methacrylate is 30-50 parts by weight, the consumption of butyl acrylate is 20-30 parts by weight, and the consumption of β-hydroxyethyl methacrylate is 10-18 parts by weight, so The dosage of the initiator is 2-5 parts by weight, and the dosage of the water is 60-90 parts by weight.

[0013] In order to make the prepared 3D printing powder have more excellent flexibility and water resistance, in a preferred embodiment of the present invention, relative to 100 parts by weight of ...

Embodiment 1

[0022] 100g polyvinyl alcohol, 35g methyl methacrylate, 23g butyl acrylate, 14g-beta-hydroxyethyl methacrylate, 3.5g benzoyl peroxide and 70g water are mixed, and heating reaction (the temperature of heating reaction is 60 ℃, the heating reaction time is 30min), and then filter to obtain the hydroxyacrylic acid copolymer resin; dry the hydroxyacrylic acid copolymer resin (the drying temperature is 40 ℃, and the drying time is 1h), and grind to obtain the hydroxyacrylic acid copolymer resin 3D printing powder (particle size 50μm).

Embodiment 2

[0024] Mix 100g polyvinyl alcohol, 45g methyl methacrylate, 27g butyl acrylate, 16g-β-hydroxyethyl methacrylate, 4.5g lauroyl peroxide and 80g water, and heat the reaction (the temperature of the heating reaction is 70°C , the heating reaction time is 40min) and then filtered to obtain the hydroxyacrylic acid copolymer resin; the hydroxyacrylic acid copolymer resin is dried (the drying temperature is 50°C, and the drying time is 2h), and the 3D acrylic acid copolymer resin is obtained after grinding. Print powder (particle size 80μm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com