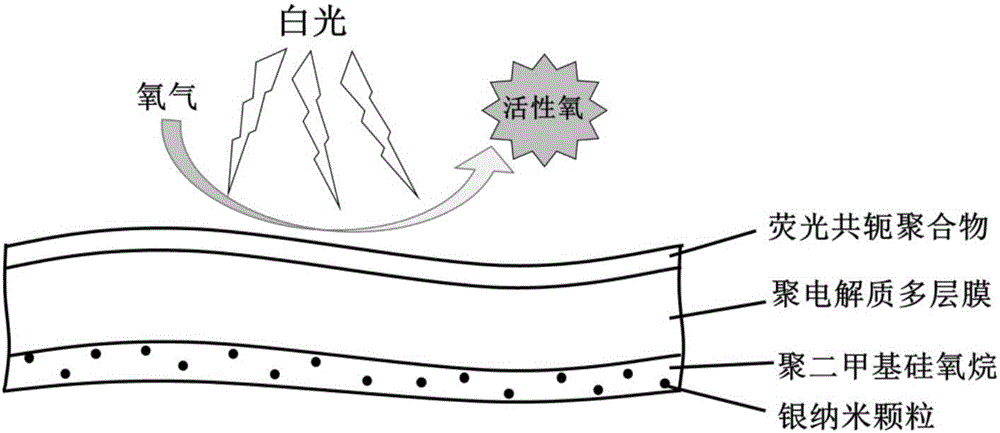

Preparation and application methods of flexible composite film with sterilization function

A composite film and flexible technology, applied in the field of functional polymer film materials, can solve the problems of inconvenient recycling and low sterilization efficiency, and achieve the effects of low cost, high-efficiency sterilization performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing and applying a flexible composite film with a bactericidal function, comprising the following steps:

[0053] Step 1. Mix polydimethylsiloxane stock solution and curing agent according to the volume ratio of 8:1, stir evenly and pour it on the quartz plate; then put it in a vacuum drying oven and let it stand for 0.5 hours; then heat up to In the temperature range of 50°C, keep warm for 0.5 hours to prepare a flexible polydimethylsiloxane film;

[0054] Step 2. Put the prepared polydimethylsiloxane film into a UV ozone light cleaner for 15 minutes; then quickly immerse it in a silver ammonia solution with a concentration of 0.05M and stir for 30 minutes; then immerse it in a silver ammonia solution with a concentration of 0.05M In the glucose solution, heat up to a temperature range of 30°C, keep warm and stir for 60 minutes; rinse and dry to obtain a flexible silver nano film;

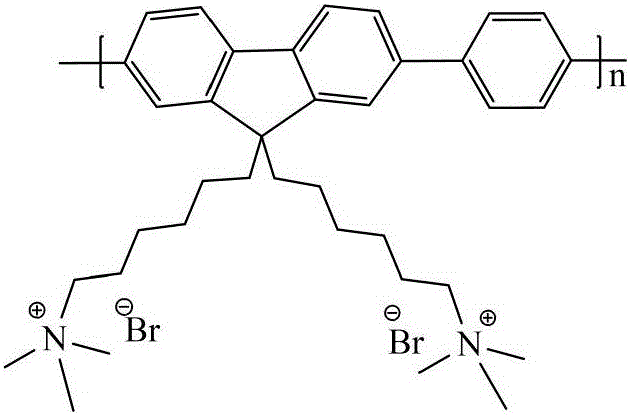

[0055]Step 3, immerse the prepared silver nanofilm in a 0.5 mg / mL p...

Embodiment 2

[0059] A method for preparing and applying a flexible composite film with a bactericidal function, comprising the following steps:

[0060] Step 1. Mix polydimethylsiloxane stock solution and curing agent according to the ratio of 10:1 by volume, stir evenly and pour it onto a polystyrene petri dish; then put it in a vacuum drying oven and let it stand for 0.5 hours ; and then heated to a temperature range of 50° C., and kept warm for 0.5 hours to prepare a flexible polydimethylsiloxane film;

[0061] Step 2. Put the prepared polydimethylsiloxane film into an ultraviolet ozone light cleaner for 15 minutes; then quickly immerse it in a silver ammonia solution with a concentration of 0.05M and stir for 30 minutes; then immerse it in a silver ammonia solution with a concentration of 0.05M In the glucose solution, the temperature was raised to within the temperature range of 50°C, kept warm and stirred for 60 minutes; rinsed and dried to obtain a flexible silver nano film;

[006...

Embodiment 3

[0066] A method for preparing and applying a flexible composite film with a bactericidal function, comprising the following steps:

[0067] Step 1. Mix polydimethylsiloxane stock solution and curing agent according to the ratio of 10:1 by volume, stir evenly and pour it onto a polystyrene petri dish; then put it in a vacuum drying oven and let it stand for 0.5 hours ; and then heated to a temperature range of 60° C., and kept warm for 2 hours to prepare a flexible polydimethylsiloxane film;

[0068] Step 2. Put the prepared polydimethylsiloxane film into an ultraviolet ozone light cleaner for 15 minutes; then quickly immerse it in a silver ammonia solution with a concentration of 0.1M and stir for 30 minutes; then immerse it in a silver ammonia solution with a concentration of 0.1M In the glucose solution, the temperature was raised to within the temperature range of 50°C, kept warm and stirred for 60 minutes; rinsed and dried to obtain a flexible silver nano film;

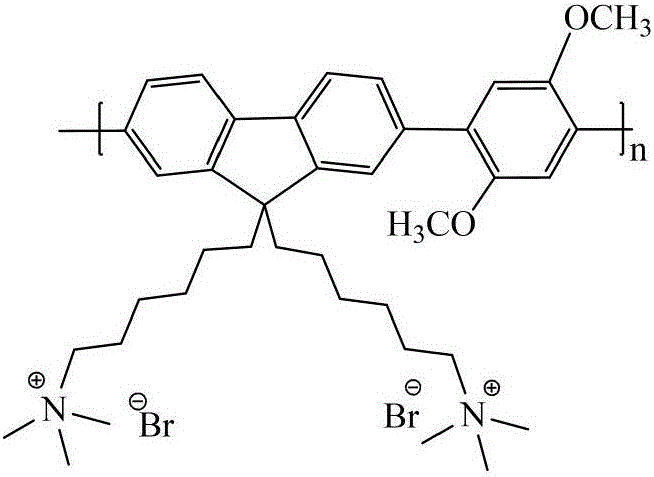

[0069] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com