Polymerizable rosin quaternary ammonium salt bactericide, preparation method thereof, and polymerized rosin quaternary ammonium salt bactericide prepared from polymerizable rosin quaternary ammonium salt bactericide

A technology for polymerizing rosin and quaternary ammonium salt compounds, which is applied in the fields of botanical equipment and methods, biocides, chemicals for biological control, etc., can solve problems such as toxicity, achieve good biocompatibility, simple synthesis process, Good and efficient bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

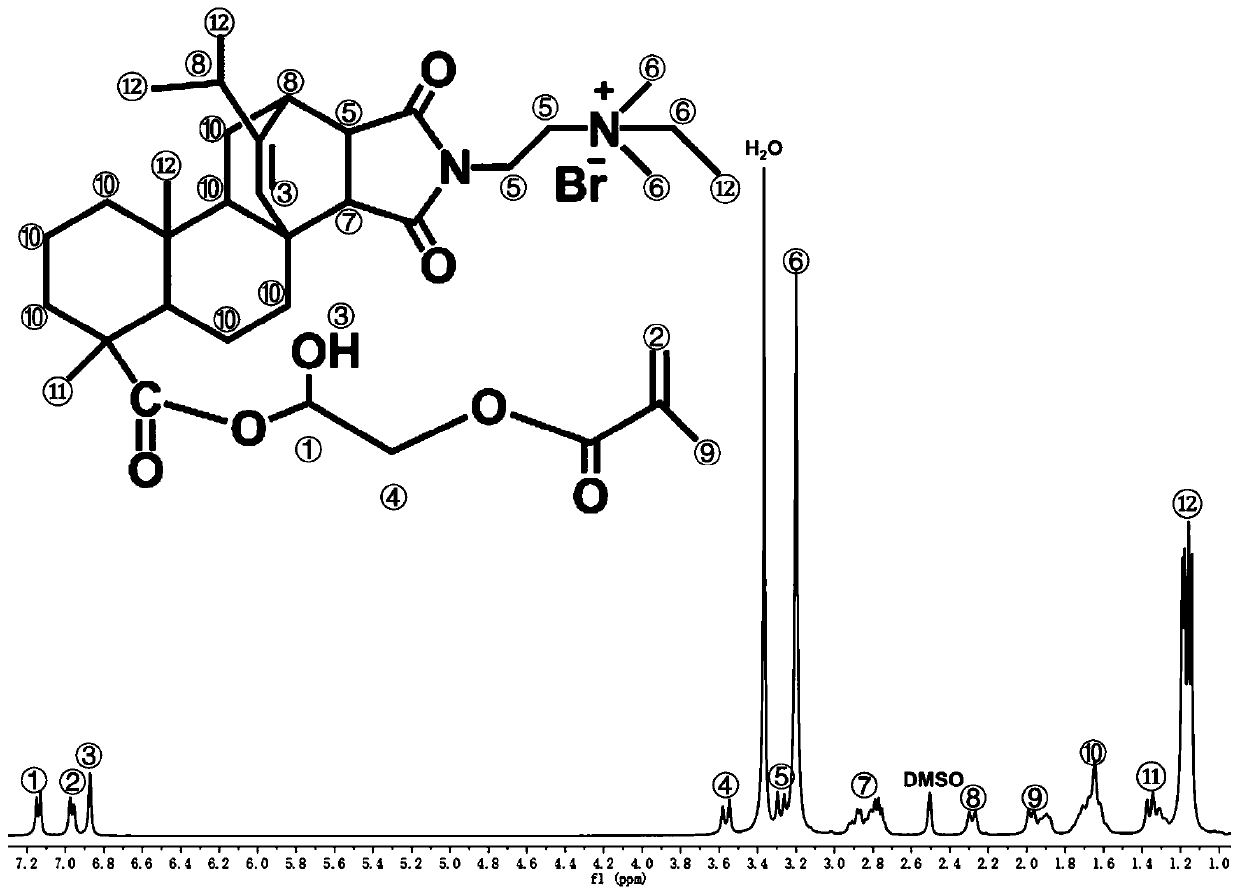

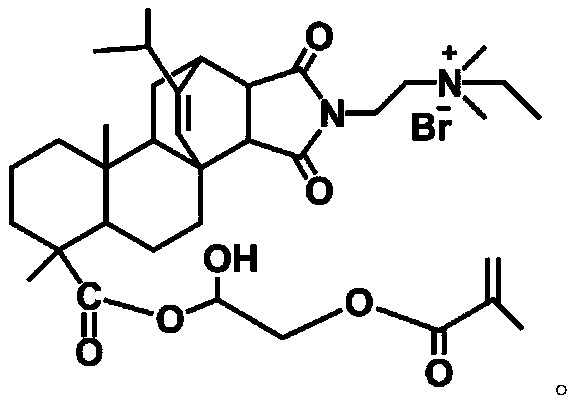

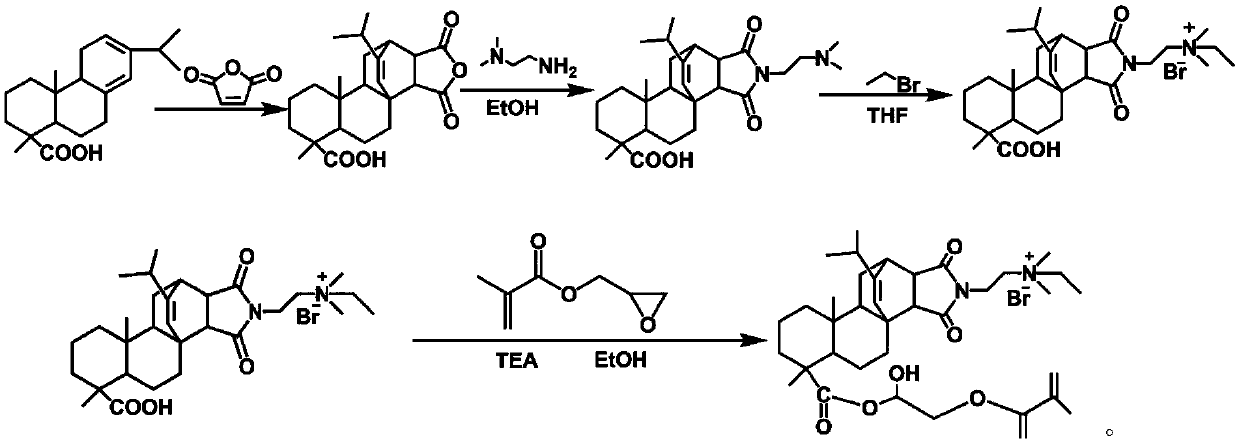

[0031] Weigh 100g of rosin and 27.5g of maleic anhydride and pour them into a 1000mL four-neck flask, then add 400mL of acetic acid and 0.128g of p-toluenesulfonic acid as a catalyst, heat to 120°C to condense and reflux, stir to make it fully react, and react for 10h Afterwards, the maleopimaric acid compound was obtained by filtration. Add 10g of maleopimaric acid and 250mL of ethanol into a 500mL four-neck flask, heat to 85°C to condense and reflux, add 2.8mL of N,N-dimethylethylenediamine dropwise, after the dropwise addition, react for 5 hours, and stand for crystallization , After filtration, the maleopimaric acid tertiary amine compound was obtained. Then add 5 g of the above-mentioned maleopimaric acid tertiary amine compound, 15.5 mL of bromoethane and 200 mL of tetrahydrofuran into a 500 mL single-necked flask, heat to 60°C to condense and reflux, stir to make it fully react, and after 30 hours of reaction, filter the product to obtain rosin quaternary ammonium comp...

Embodiment 2

[0033] The preparation of the maleopimaric acid compound refers to Example 1; 5 g of maleopimaric acid and 200 mL of ethanol were added to a 500 mL four-neck flask, heated to 80 ° C, condensed and refluxed, and 1.4 mL of N,N-dimethylethylenediamine was added dropwise , After the dropwise addition, react for 6h, stand to crystallize, and obtain maleopimaric acid tertiary amine compound after filtration. Then add 10 g of the above maleopimaric acid tertiary amine compound, 40 mL of bromoethane and 300 mL of tetrahydrofuran into a 500 mL single-necked flask, heat to 65°C to condense and reflux, stir to make it fully react, and after 32 hours of reaction, filter the product to obtain rosin quaternary ammonium salt compound. Add 10 g of the above-mentioned rosin quaternary ammonium salt compound, 2.42 g of glyceryl methacrylate, 0.13 g of benzyltriethylammonium chloride and 500 mL of ethanol into a 1000 mL single-necked flask, heat to 80 ° C, react for 5 hours, and remove the ethan...

Embodiment 3

[0035] Polymerizable rosin quaternary ammonium salt with reference to Example 2; Polymerizable rosin quaternary ammonium salt 10g and 5mg initiator (4,4'-azobis (4-cyanovaleric acid)) are dissolved in 150mL ethanol, then add Put it into a 500mL four-necked flask, heat to 80°C, condense and reflux, stir to make it fully react, and after reacting for 8 hours, remove ethanol by rotary evaporation to obtain a polymerized rosin quaternary ammonium salt fungicide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com