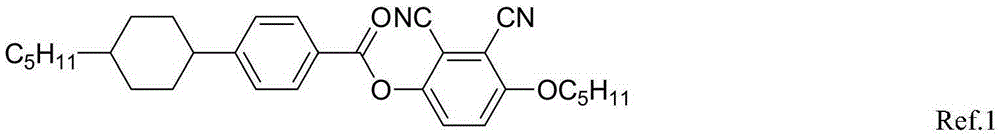

Liquid crystal compound having negative dielectric anisotropy and application thereof

An anisotropic, liquid crystal composition technology, applied in organic chemistry, liquid crystal materials, nonlinear optics, etc., can solve the problems of poor mutual solubility, high viscosity, and poor photostability of liquid crystal monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

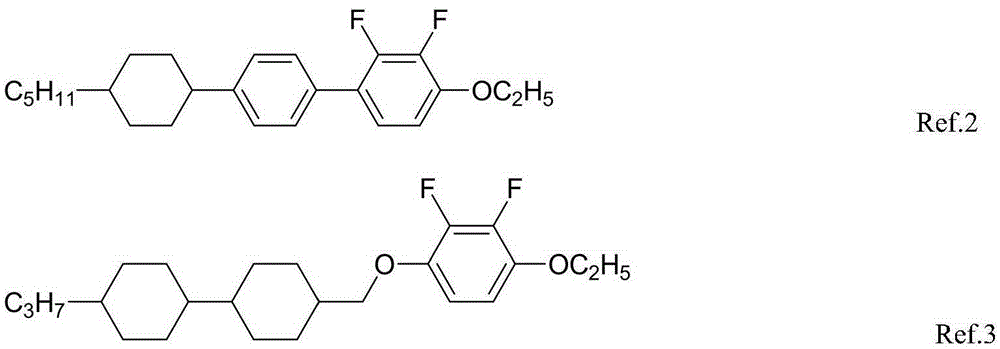

[0104] Compound Ⅰ-A-9 synthetic route is as follows:

[0105]

[0106] 1) Synthesis of Compound B

[0107] In a 500ml three-necked flask, add 8.6g compound A, 9.7g 2,3-difluorobromobenzene, 100ml toluene, 50ml ethanol, 50ml water, 21.2g sodium carbonate, under nitrogen protection, add 0.3g Pd(PPh3)4, heat After refluxing for 6 hours, separate liquid, wash with water, and column chromatography to obtain 10.1 g of white solid compound B, GC>97%, yield: 84.2%

[0108] 2) Synthesis of Compound D

[0109] In a 250ml three-necked flask, add 6g of compound B and 100ml of anhydrous tetrahydrofuran, under the protection of nitrogen, cool down to -78°C, add 10.5ml of n-butyllithium n-hexane solution (2.4mol / L) dropwise, keep stirring for 2h, add dropwise 2.6 g of compound C and 10 ml of anhydrous tetrahydrofuran mixed solution, and temperature controlled to between -65 ~ -70 ° C, after the dropwise addition, keep stirring for 1 h, then pour the reaction solution into the ice-water ...

Embodiment 2

[0127] Compound I-A-9, Compound I-A-11, Compound I-B-9, Compound V were mixed with the host liquid crystal (host) at a ratio of 10:90, and the liquid crystal parameters of each compound were tested by extrapolation method as shown in Table 2. Show:

[0128]

[0129] Table 2

[0130] Cp(°C) Δn Δε VHR(%) T -10℃

Ⅰ-A-9 75.2 0.126 -8.2 97.0 >144h Ⅰ-A-11 71.6 0.12 -8.0 97.1 >144h Ⅰ-B-9 62.6 0.124 -8.5 97.0 >144h Ⅴ 183 0.18 -5.7 94.0 <72h

host 112 0.08 5.0 98.1 -

[0131] Note: T -10℃ Indicates the storage stability of the mixture composed of compound Ⅰ-A-9, Ⅰ-A-11, Ⅰ-B-9, Ⅴ and the host liquid crystal host in a ratio of 10:90 at -10°C.

[0132] Compared with the compound V in the prior art, the compound of the present invention has larger absolute value of dielectric anisotropy, higher voltage retention rate and stable low-temperature stability.

Embodiment 3

[0134] The liquid crystal composition of Example 3 was prepared by each compound listed in Table 3 and the weight percentage, which was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0135] Table 3 liquid crystal composition formula and test performance thereof

[0136]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com