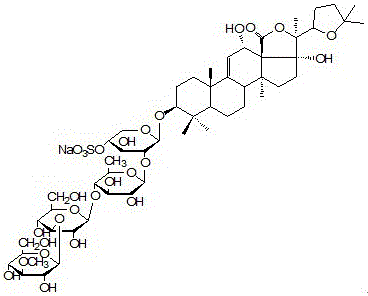

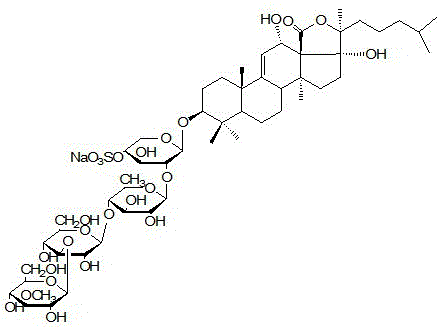

Deglycosylated holothurian secondary saponin and preparation method thereof

A technology for secondary saponins and sea cucumber saponins is applied in the field of enzymatic hydrolysis and preparation of sea cucumber saponins, which can solve the problems of less enzymatic hydrolysis of sea cucumber saponins, many side reactions, poor specificity and the like, and achieves improved biological activity, single product, and reduced toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

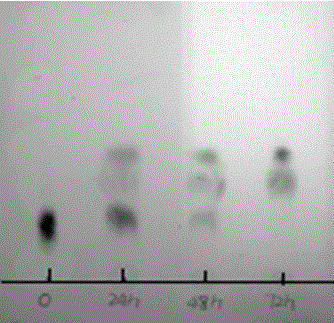

Examples

Embodiment 1

[0041] (1) Put the purchased dried sea cucumber into an oven at 50°C, take it out after 2 days, and crush it into powder;

[0042] (2) Take dried sea cucumber powder (Philippine sea cucumber about 1 kg), extract it with 60% ethanol for 7 days, stir continuously during this period, extract 3 times, evaporate under reduced pressure to obtain extract paste, and freeze-dry to obtain crude extract;

[0043] (3) Dissolve the above crude extract fully with a small amount of water first, and then extract five times with water-saturated n-butanol. The first time extracts the sample and water-saturated n-butanol 1:3 (v / v), and then extracts it twice with water-saturated n-butanol. 1:2 (v / v) extraction, the last two extractions were 1:1 (v / v). Concentrate the supernatant under reduced pressure to obtain extract extract, and evaporate to dryness in a 60°C water bath to obtain crude saponin powder;

[0044] ⑷, enrich the thick saponin in step ⑶ with macroporous resin column chromatography...

Embodiment 2

[0053] (1) Put the purchased dried sea cucumber into an oven at 50°C, take it out after 2 days, and crush it into powder;

[0054] (2) Take dried sea cucumber powder (Philippine sea cucumber about 1kg), extract it with 60% ethanol for 7 days, keep stirring during the period, extract 3 times, evaporate under reduced pressure to obtain extract paste, freeze dry in a freeze dryer to obtain crude extract ;

[0055] (3) Dissolve the above crude extract fully with a small amount of water first, and then extract five times with water-saturated n-butanol. The first time extracts the sample and water-saturated n-butanol 1:3 (v / v), and then extracts it twice with water-saturated n-butanol. 1:2 (v / v) extraction, the last two extractions were 1:1 (v / v). Concentrate the supernatant under reduced pressure to obtain extract extract, and evaporate to dryness in a 60°C water bath to obtain crude saponin powder;

[0056] ⑷, enrich the thick saponin in the step ⑶ with macroporous resin column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com