Magnetically soft alloy strip based on high-plasticity high silicon and manufacturing method of magnetically soft alloy strip

A technology of soft magnetic alloy and manufacturing method, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve problems such as difficult conventional rolling process preparation, decreased elongation performance, poor processing performance, etc., to improve process and product quality The effect of stabilizing, improving flatness and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

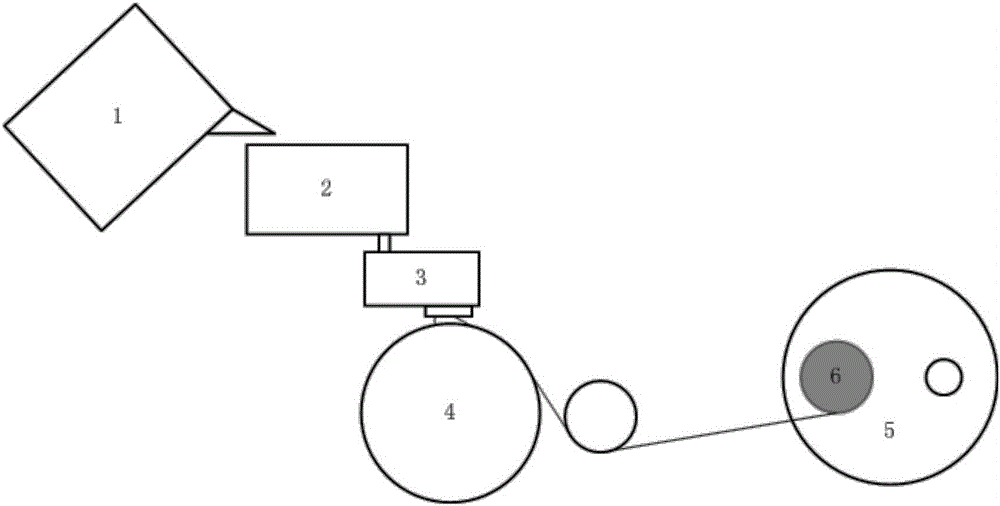

[0036] combine figure 1 , a method of manufacturing soft magnetic alloy strips based on large plasticity and high silicon content proposed by the present invention adopts the improved planar flow casting method and the traditional isothermal annealing treatment method. The basic process includes batching and master alloy smelting, steel Liquid-killed, high-speed continuous casting of high-silicon silicon steel strips with large plasticity, on-line coiling of alloy strips, and isothermal annealing treatment. A soft magnetic alloy strip based on large plasticity and high silicon proposed by the present invention can use pure iron, ferroboron, and ferrosilicon as raw materials for master alloy smelting, and melt the raw materials in an induction furnace or other smelting furnace 1 And perform overheating treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com