Aluminum electrolysis flue gas purification method and dust collector

A technology of flue gas purification and dust collector, which is applied in the field of electrolytic flue gas purification in the aluminum electrolysis industry, can solve the problems that the activity of fresh alumina is not fully utilized, affects the purification efficiency of alumina to hydrogen fluoride, and the purification effect is not ideal, and achieves the goal of working High efficiency, reduced burden, good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

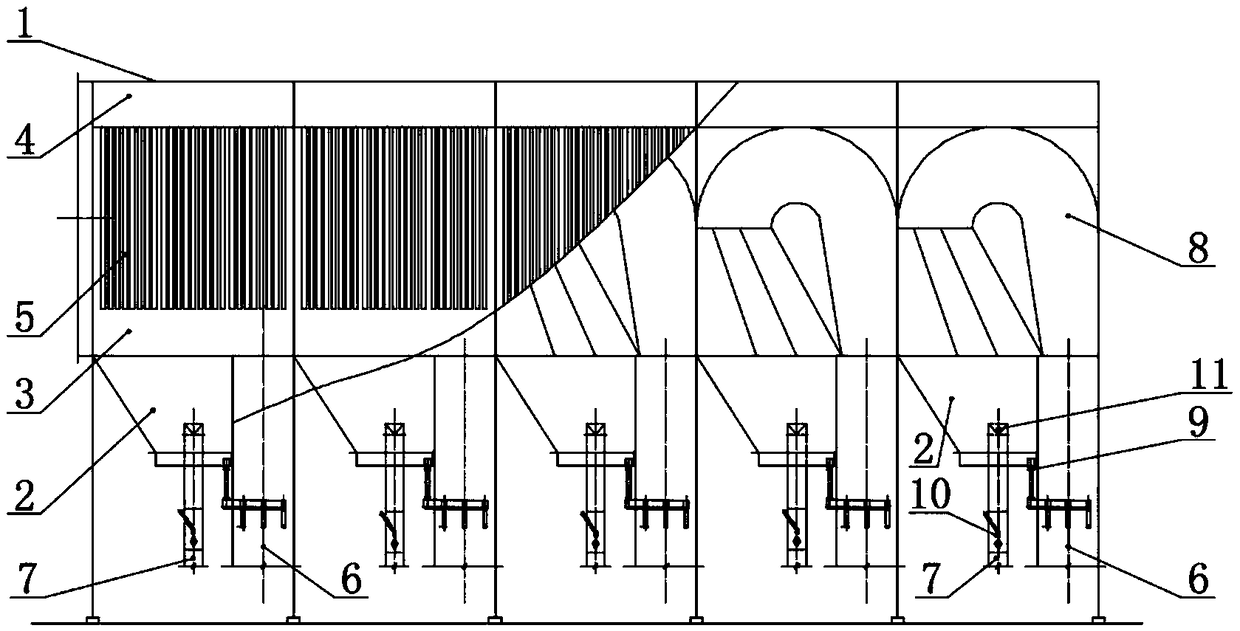

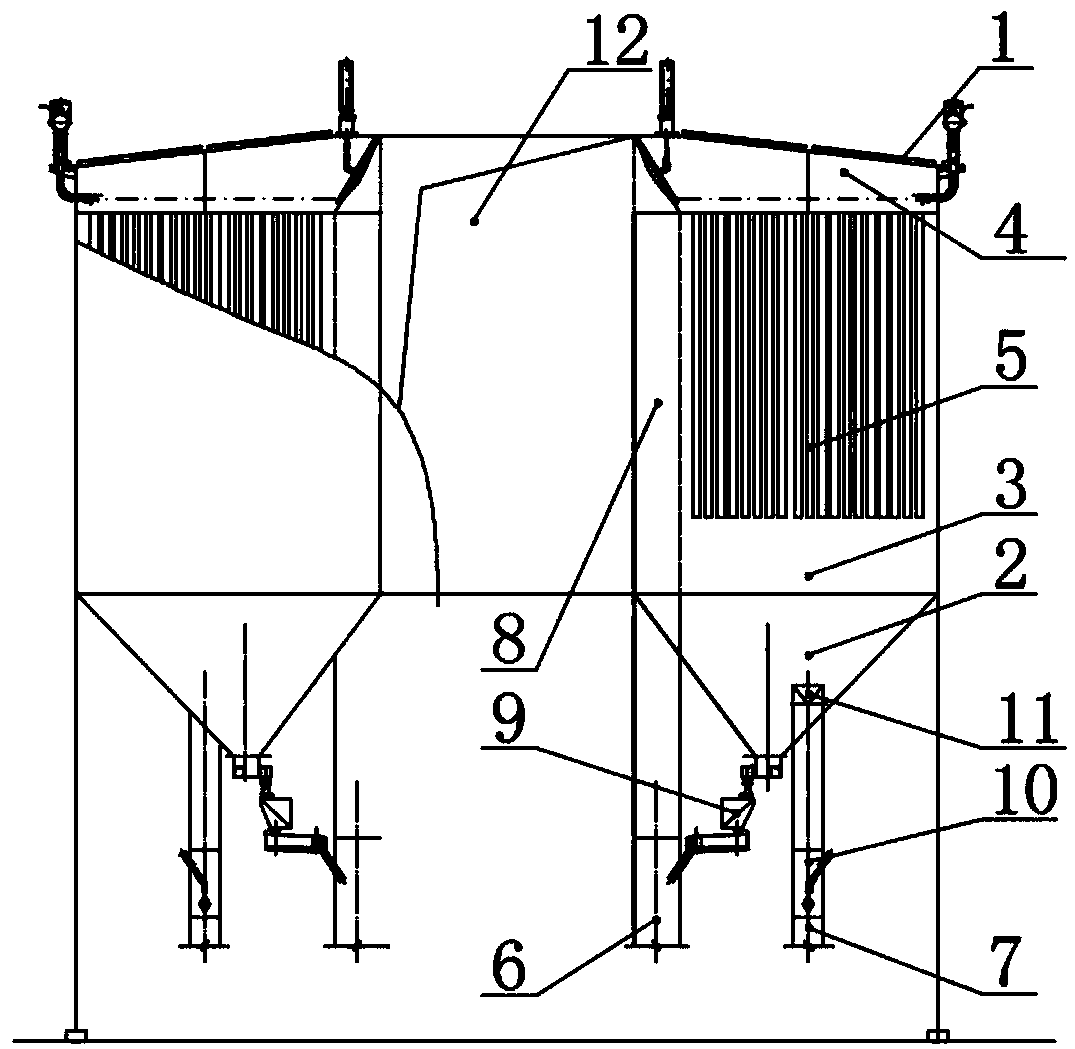

[0020] The present invention is implemented like this, as figure 1 As shown, the flue gas enters the dust collector unit 1 from the main flue 6 and the auxiliary flue 7 respectively. Utilizing the main flue 6 and the auxiliary flue 7 which are set independently, the adsorbent fresh alumina and fluorine-containing alumina are respectively added to the purification system. A large amount of fluorine-containing alumina is added to the system from the main flue 6 to pre-purify the electrolytic flue gas to reduce the concentration of harmful substances in the flue gas to a low level, and then the fluorine-containing alumina passes through the upper part of the main flue 6. The inverted U-shaped inertial separation device 8 is separated into the ash hopper 2, reducing the burden on the filter bag 5, reducing the wear of the filter bag 5 of the dust collector and reducing the system resistance. Fresh alumina is added to the system through the auxiliary flue 7, and under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com