Preparation method of curtain fibers capable of degrading indoor toxic gas by utilizing visible light and infrared light

A technology of toxic gas and infrared light, applied in the field of curtain fibers, can solve the problems of only absorption and large forbidden band width, and achieve the effect of rapid degradation and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) 200 g of Bi with an average particle size of 120 nm 0.895 Yb 0.1 Er 0.005 OBr powder, 300 g nano-silica, 10 g polyether modified polysiloxane wetting agent and 490 g polyamide pellets are mixed and put into the extruder, and the working temperature of the extruder is 200 Extrude at ℃, and obtain functional pellets after pelletizing.

[0020] (2) Add the functional pellets obtained in (1) into the pellets, in which the functional masterbatch accounts for 4% by mass, put it into the extruder after mixing, extrude at 230°C, and spin Silk obtains infrared light to degrade toxic gases in indoor curtain fibers.

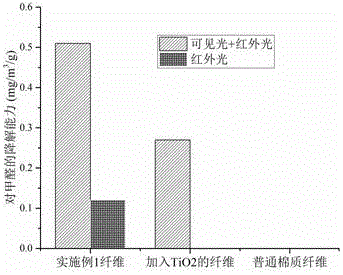

[0021] Embodiment 1 gained curtain fiber material property, and see with other material fiber contrast figure 1 . It can be seen that under visible light irradiation, compared with other fibers, the fiber obtained in Example 1 has the highest degradability; and under infrared light: other materials will not degrade formaldehyde at all, but the fiber obtained...

Embodiment 2

[0023] (1) 100 g of Bi with an average particle size of 70 nm 0.895 Yb 0.1 Er 0.005 OBr powder, 450 g of nano-silica, 10 g of polysiloxane wetting agent and 440 g of polyamide pellets are mixed and put into the extruder, and extruded at the working temperature of the extruder at 250°C , to obtain functional pellets after pelletizing.

[0024] (2) Add the functional pellets obtained in (1) into the pellets, in which the functional masterbatch accounts for 7% by mass, put it into the extruder after mixing, extrude at 250°C, and spin Silk obtains infrared light to degrade toxic gases in indoor curtain fibers.

Embodiment 3

[0026] (1) 300 g of Bi with an average particle size of 300 nm 0.895 Yb 0.1 Er 0.005 OBr powder, 150 g of nano-silica, 10 g of polysiloxane wetting agent and 540 g of polyamide pellets are mixed and put into the extruder, and extruded at the working temperature of the extruder at 190°C , to obtain functional pellets after pelletizing.

[0027] (2) Add the functional pellets obtained in (1) into the pellets, in which the functional masterbatch accounts for 2% by mass, put it into the extruder after mixing, extrude at 200°C, and spin Silk obtains infrared light to degrade toxic gases in indoor curtain fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com