A kind of improved expansive soil roadbed filler and preparation method thereof

A soil roadbed and expansive soil technology, applied in the field of roadbed filling, can solve the problems of high cost, environmental pollution, poor effect, etc., achieve the effect of weakening hydrophilicity, reducing project cost, and improving expansion and contraction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

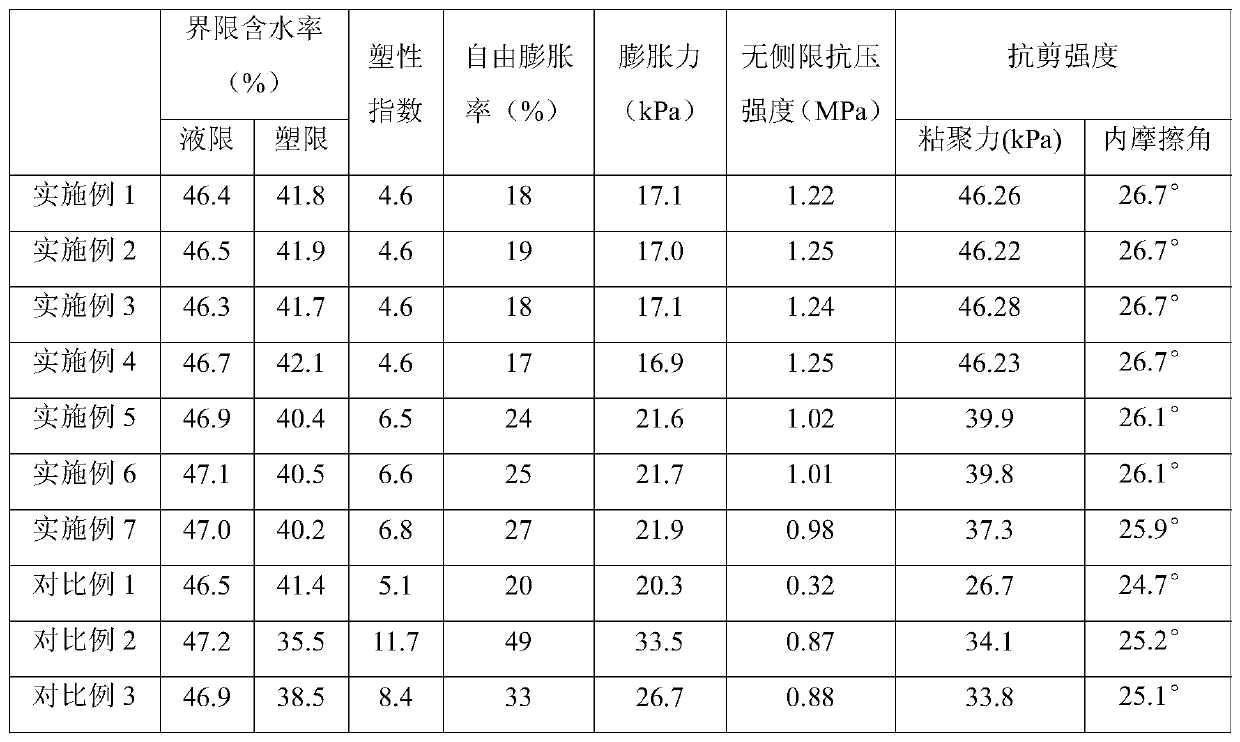

Examples

preparation example Construction

[0023] The present invention also provides a method for preparing an improved expansive soil roadbed filler, the method comprising: first mixing the expansive soil and slaked lime to form a first mixture, performing second mixing of polyaluminum chloride and water to form a second mixture, The first mixture is then subjected to a third mixing with the second mixture.

[0024] In the present invention, in the present invention, the meaning of the expansive soil is well known to those skilled in the art. According to the evaluation of expansive soil sites in 5.5.2 of the "Special Geotechnical Investigation Regulations for Railway Engineering", free expansion rate ≥ 40%, montmorillonite content ≥ 7%, and cation exchange capacity ≥ 170mmol / Kg meet any of the two and above are judged as expansive soil.

[0025] In the present invention, the meaning of the polyaluminum chloride is well known to those skilled in the art, and it can be obtained commercially or prepared by conventiona...

Embodiment approach

[0030] In the present invention, the conditions for the second mixing are not particularly limited, as long as the polyaluminum chloride and water can be uniformly mixed. For example, the conditions for the second mixing include: the temperature may be 5-40° C., and the time may be 0.05-0.25 hours. The second mixing can be performed under stirring. According to a preferred embodiment, the second mixing includes: gradually adding polyaluminum chloride into water until it is completely dissolved.

[0031] In the present invention, the amount of polyaluminum chloride and water used for the second mixing can vary within a wide range. For example, the weight ratio of the polyaluminum chloride to water may be 0.2-0.45:1, preferably 0.3-0.35:1.

[0032] In the present invention, the conditions of the third mixing are not particularly limited, as long as the first mixture and the second mixture can be uniformly mixed. For example, the conditions of the third mixing include: the tem...

Embodiment 1

[0041] This example is used to illustrate the improved expansive soil roadbed filler provided by the present invention and its preparation method

[0042] Take by weighing the expansive soil of 117.4g (dry weight is 100g) and the hydrated lime of 3.06g (dry weight is 3g, and the content of the slaked lime that particle size is greater than 0 less than 0.17mm is 99% by weight, and the content of the slaked lime of 0.17-0.2mm is 1 weight % %), using a forced mixer to stir at a speed of 35 rpm for 30 min at 25° C. and mix uniformly to form the first mixture. Weighed 1.2g of polyaluminum chloride (dry weight: 1.2g), gradually added 3.6g of water under stirring (25°C, 40rpm), stirred for 6min and mixed uniformly to form a second mixture.

[0043] At 25°C, use a sprayer to spray the second mixture at a rate of 200g / min onto the surface of the first mixture under stirring, and continue stirring for 20 minutes after spraying to obtain improved expansive soil roadbed filler A1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com