Cotton-free non-metallic compound sound barrier and preparation method thereof

A composite sound, non-metal technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of difficult to use durable, unstable structure, easy to weathering, etc., to achieve long service life, simple structure, convenient production and installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

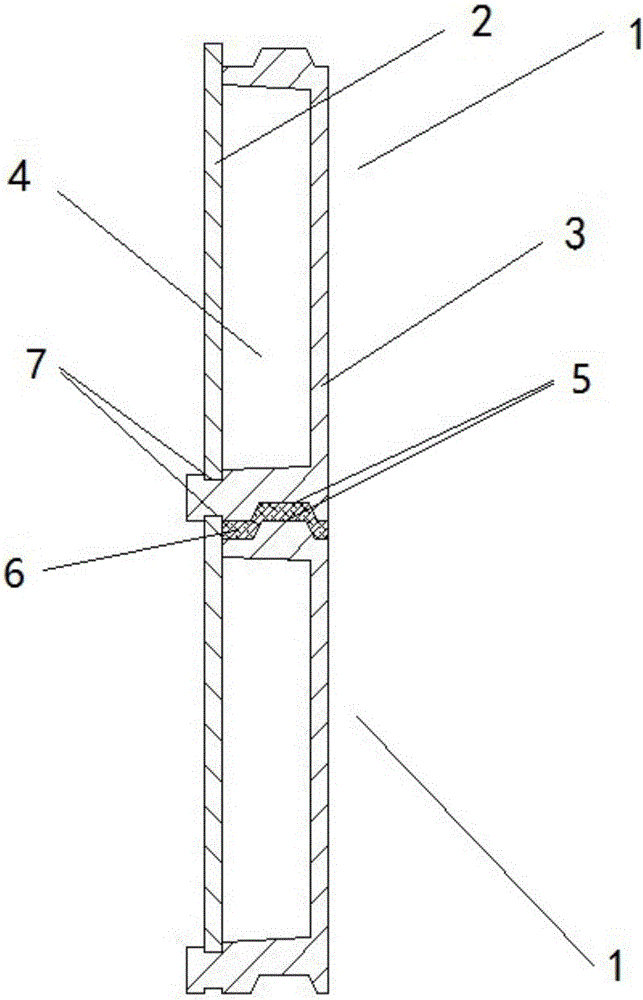

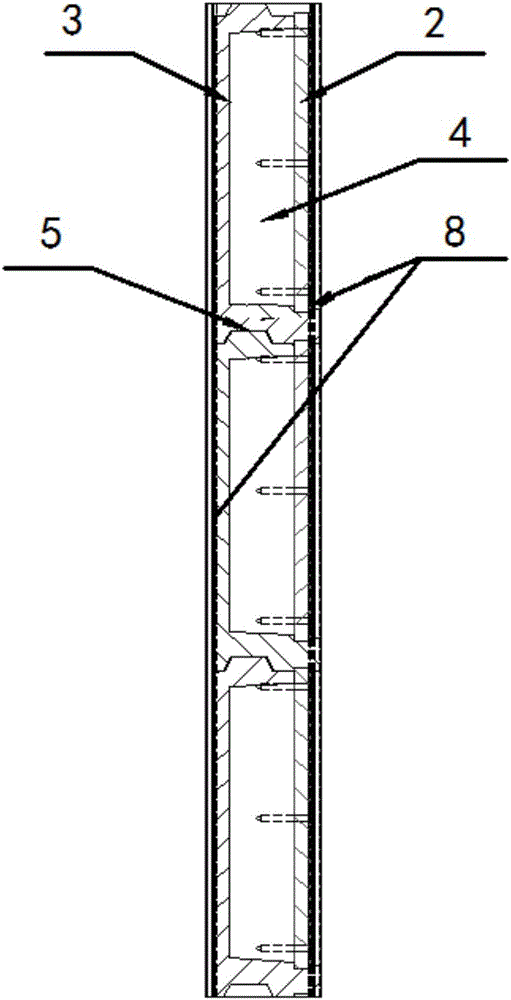

[0029] A cotton-free non-metallic composite sound barrier of this embodiment is formed by connecting and assembling six barrier monomers 1 with hollow bodies 4 up and down, such as figure 1 As shown (two pieces are shown in the figure), each barrier unit 1 is bonded by a microporous rock-absorbing sound-insulating board 2 and a groove-shaped cement member 3, and the two surround the cavity body 4 in a square shape. cavity. The surface 2 of the microporous rock sound-absorbing and sound-insulating board is in the shape of waves, and of course it can also be in the shape of a flat plate or other shapes. The microporous rock-absorbing and sound-insulating board of this embodiment is 1960 mm long, 400 mm wide, and 15 cm thick. The height of the cavity body perpendicular to the direction of the microporous rock-absorbing and sound-insulating board is 100 mm.

[0030] The upper and lower cement floors of the adjacent cement components 3 of each group of upper and lower adjacent ba...

Embodiment 2

[0035] A cotton-free non-metallic composite sound barrier of this embodiment is formed by connecting and assembling six barrier monomers 1 with hollow bodies 4 up and down, such as figure 1 As shown (two pieces are shown in the figure), each barrier monomer 1 is bonded by microporous rock-absorbing and sound-insulating panels 2 and groove-shaped cement components 3, and the two surround the cavity body 4 as a circle shaped cavity. The surface 2 of the microporous rock-absorbing and sound-insulating board is a flat plate. The microporous rock-absorbing and sound-insulating board of this embodiment is 3960 mm long, 500 mm wide, and 25 cm thick. The height of the cavity body perpendicular to the direction of the microporous rock-absorbing sound-insulating board is 140mm

[0036] The upper and lower cement floors of the adjacent cement components 3 of each group of upper and lower adjacent barrier monomers 1 fit each other through the concave-convex structure 5, and there may be...

Embodiment 3

[0041] A cotton-free non-metallic composite sound barrier of this embodiment is formed by connecting and assembling six barrier monomers 1 with hollow bodies 4 up and down, such as figure 1 As shown (two pieces are shown in the figure), each barrier unit 1 is bonded by a microporous rock-absorbing sound-insulating board 2 and a groove-shaped cement member 3, and the two surround the cavity body 4 in a trapezoidal shape cavity. The surface 2 of the microporous rock absorption and sound insulation board is a corrugated surface. The microporous rock-absorbing and sound-insulating board of this embodiment is 2000 mm long, 450 mm wide, and 20 cm thick. The height of the cavity body perpendicular to the direction of the microporous rock-absorbing sound-insulating board is 120 mm.

[0042] The upper and lower cement floors of the adjacent cement components 3 of each group of upper and lower adjacent barrier monomers 1 fit each other through the concave-convex structure 5, and there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com