Nitrogen blockage prevention and control method for argon generation system of air separation device

An air separation device, prevention and control technology, applied in the field of air separation control engineering, can solve problems such as strong loop coupling and inability to adapt to the dynamic characteristics of air separation argon operation, and achieve low model requirements, convenient online calculation, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

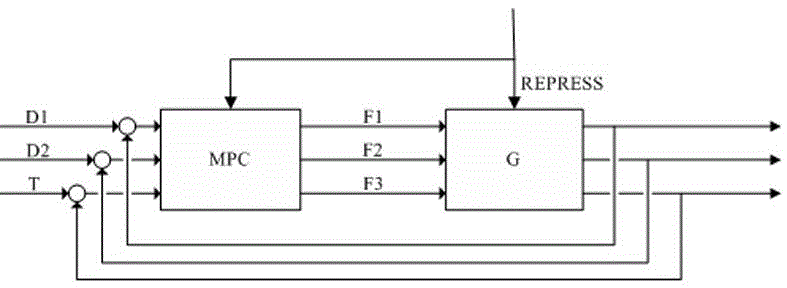

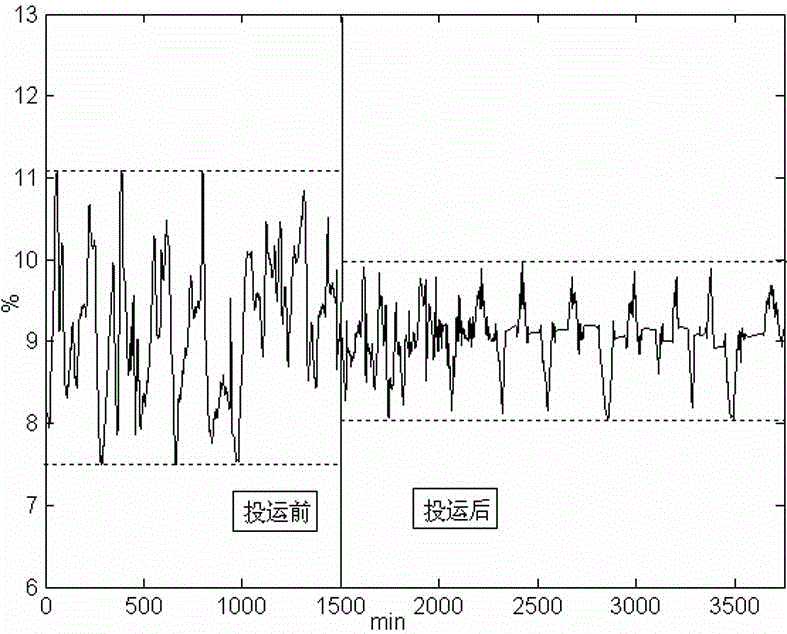

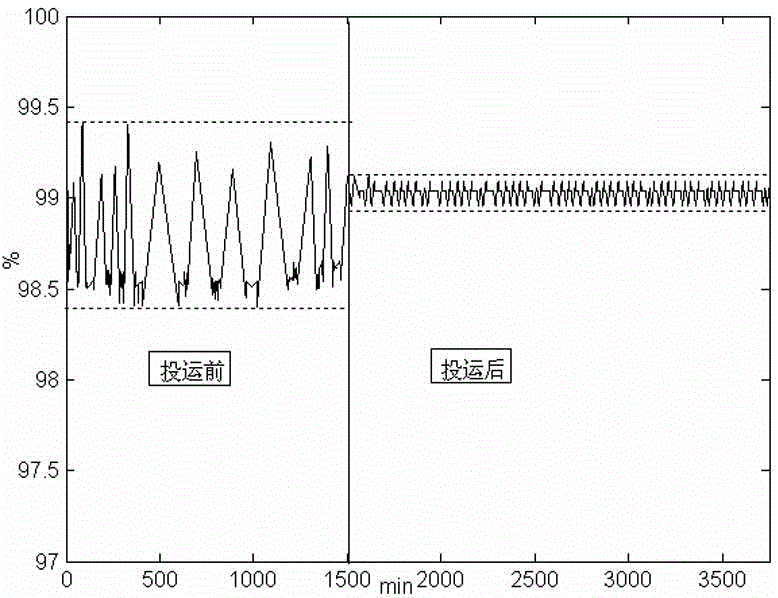

[0050] Embodiment: the present invention takes figure 1 The air separation unit in the internal compression process shown is taken as an example. Under standard operating conditions, the oxygen output of the air separation unit is 20000Nm 3 / h, the specific implementation steps of its control method are:

[0051] ⑴. According to the air separation argon process and control requirements, the argon content of the argon fraction, the temperature of the argon fraction and the argon content at the top of the crude argon tower II are selected as the controlled variables. As the operating variable, the molecular sieve switching step-up process is introduced as an event variable into the disturbance variable of the controller;

[0052] (2) Obtain the required identification data through the step test of each operating variable, and use the identification software FRONT-ID to identify the first-order transfer function between the amount of gas and oxygen taken out, the return rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com