Optical fiber mini-sized hydrophone

A hydrophone and optical fiber technology, applied in the field of optical fiber micro hydrophones, can solve the problems of complex membrane processing technology, reduce mechanical sensitivity, reflected light signal error, etc., so as to improve detection accuracy, reduce production cycle, and improve deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

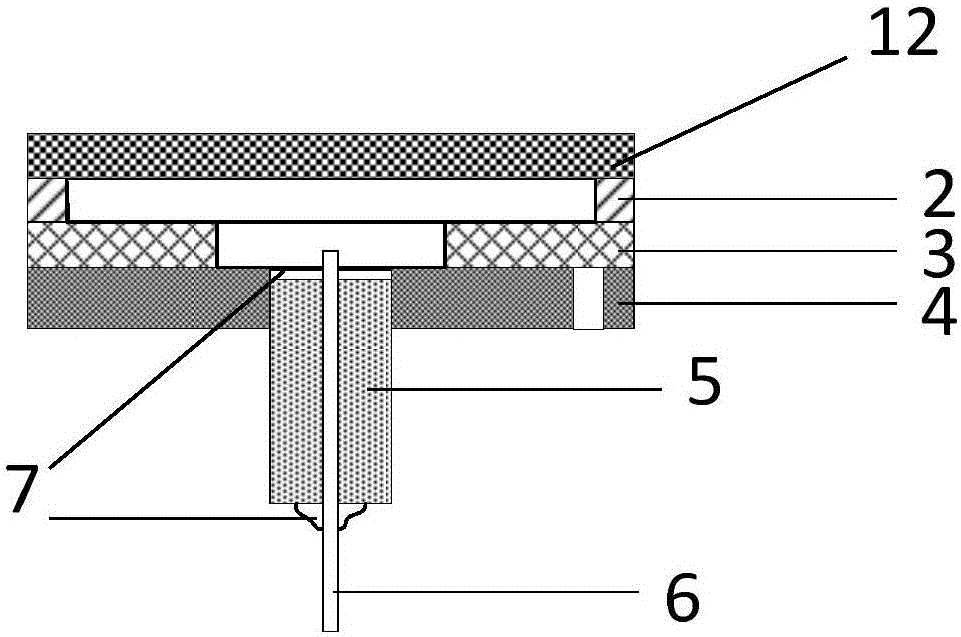

[0033] The optical fiber miniature hydrophone of the present embodiment, structural schematic diagram is as figure 1 shown. The fiber optic miniature hydrophone includes a four-layer structure, the first layer is a diaphragm, and the diaphragm is a PDMS flat membrane 12, the second layer is the first support layer 2 with a circular through hole in the center, and the third layer is the center There is the second support layer 3 with circular through holes, the fourth layer is the third support layer 4 with circular through holes in the center and vent holes at the edge; diaphragm, first support layer 2, second support layer 3 and the second support layer The three supporting layers 4 are sequentially aligned and bonded together; the diameters of the circular through holes of the first supporting layer 2, the second supporting layer 3 and the third supporting layer 4 are successively reduced and arranged in steps; in the third supporting layer A ferrule 5 is installed in the c...

specific Embodiment 2

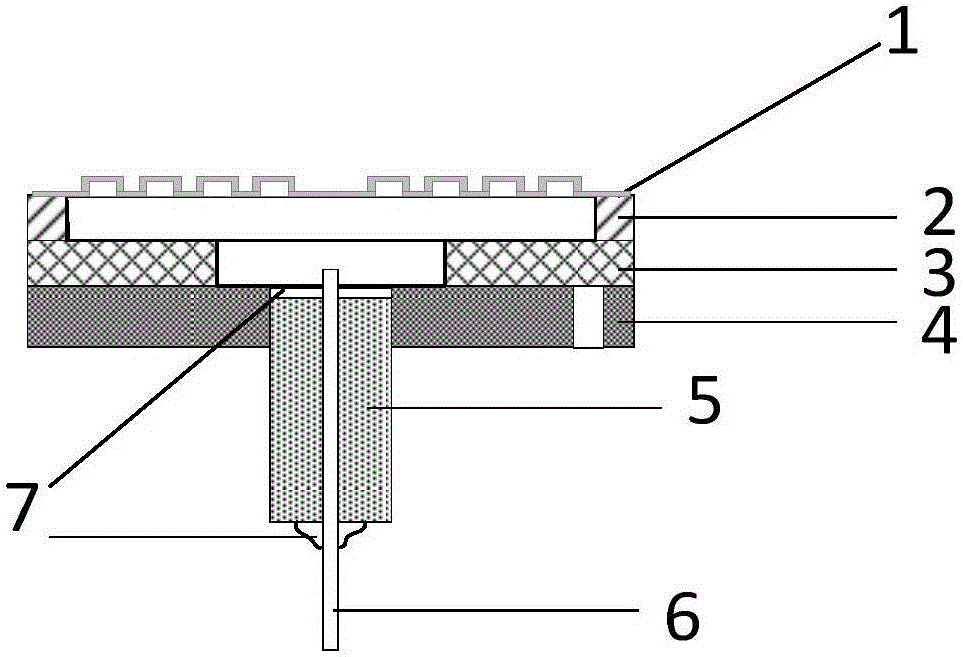

[0035] The optical fiber miniature hydrophone of the present embodiment, structural schematic diagram is as figure 2 shown. The fiber optic miniature hydrophone includes a four-layer structure, the first layer is a diaphragm, and the diaphragm is a PET textured film 1, the second layer is a first support layer 2 with a circular through hole in the center, and the third layer is a central There is the second support layer 3 with circular through holes, the fourth layer is the third support layer 4 with circular through holes in the center and vent holes at the edge; diaphragm, first support layer 2, second support layer 3 and the second support layer The three supporting layers 4 are sequentially aligned and bonded together; the diameters of the circular through holes of the first supporting layer 2, the second supporting layer 3 and the third supporting layer 4 are successively reduced and arranged in steps; in the third supporting layer A ferrule 5 is installed in the circu...

specific Embodiment 3

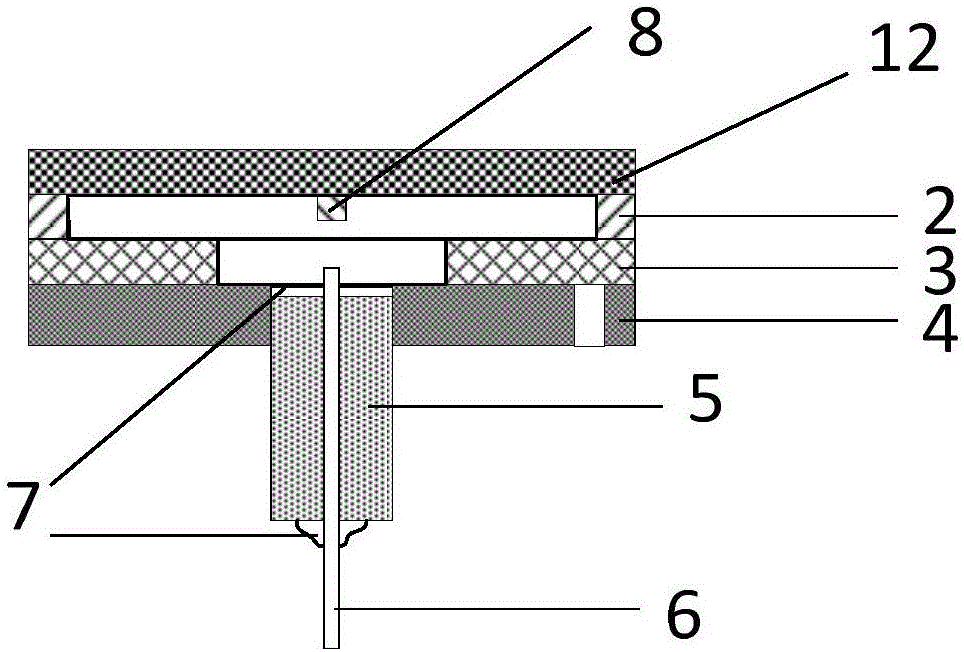

[0037] The fiber optic miniature hydrophone of the present embodiment, on the basis of the specific embodiment one, is further limited to be coated with a metal layer 8 in the middle of the PDMS flat film 12, as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com