System for detecting potential safety hazards of hydraulic structure

A technology for hydraulic structures and safety hazards is applied in the field of safety hazards detection systems, which can solve the problems of damage to detected objects, inefficiency of destructive detection methods, and difficulty in meeting sluice engineering inspections, so as to avoid losses and ensure normal use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

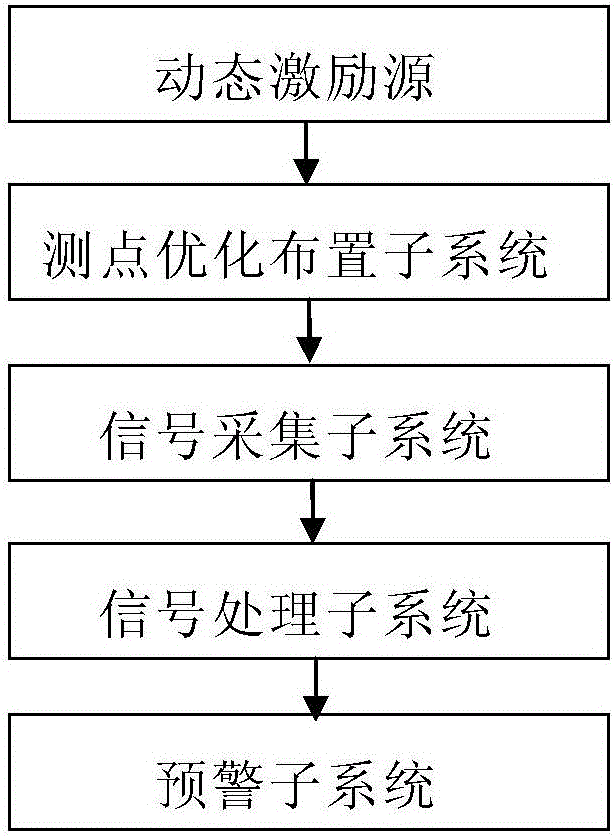

[0029] like figure 1 As shown, the potential safety hazard detection system for hydraulic structures disclosed by the present invention includes a dynamic excitation source, a measurement point optimization layout subsystem, a signal acquisition subsystem, a signal processing subsystem, and an early warning subsystem;

[0030] The dynamic excitation source is used to excite the hydraulic structure externally, causing the hydraulic structure to vibrate and send out a dynamic response signal. The dynamic excitation source can be one or a combination of environmental excitation, artificial excitation, electromagnetic wave, ultrasonic wave, radar, seismic wave, etc.

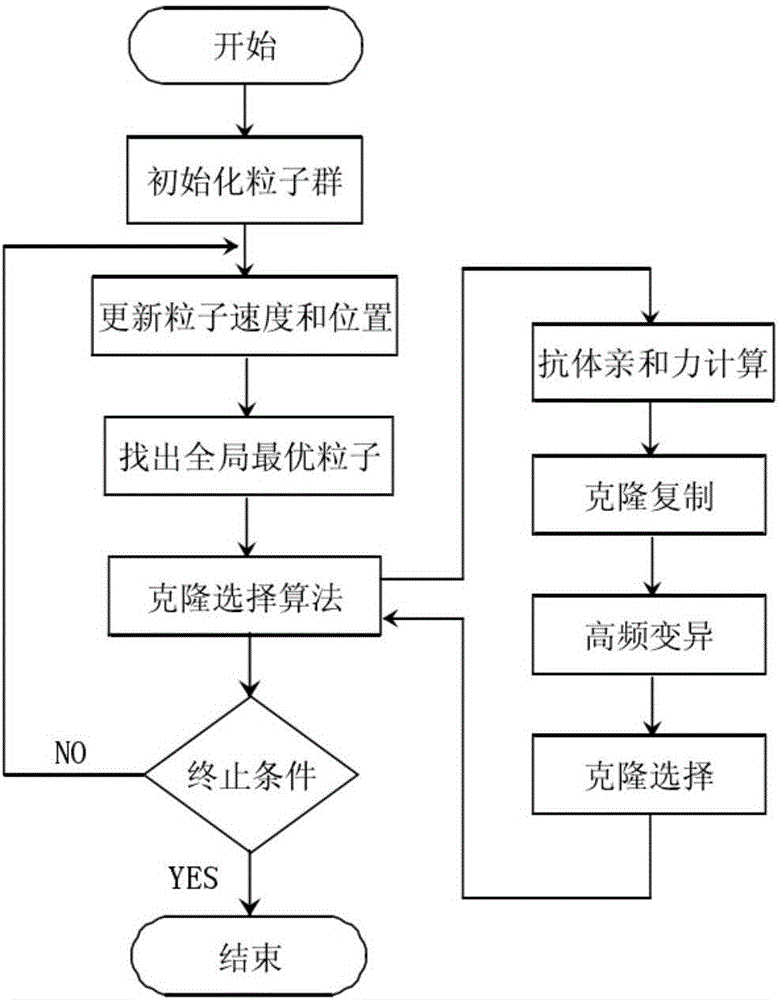

[0031] The measurement point optimization layout subsystem is used to obtain the optimal layout position of the sensor based on a specific algorithm according to the specific struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com