Fast neutron reactor high-burnup metal fuel element with graphite foam as heat-conducting medium

A heat-conducting medium and graphite foam technology, which is applied in the field of nuclear engineering, can solve the problems of accelerating the diffusion of lanthanide fission products and the inconvenience of fuel post-processing, and achieve the effects of improving the overall economy, stable structure and performance, and improving the fuel consumption life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

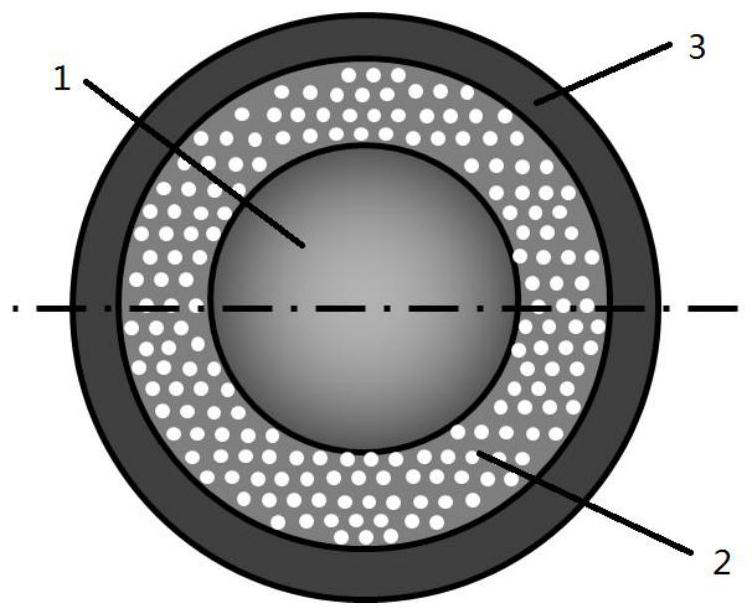

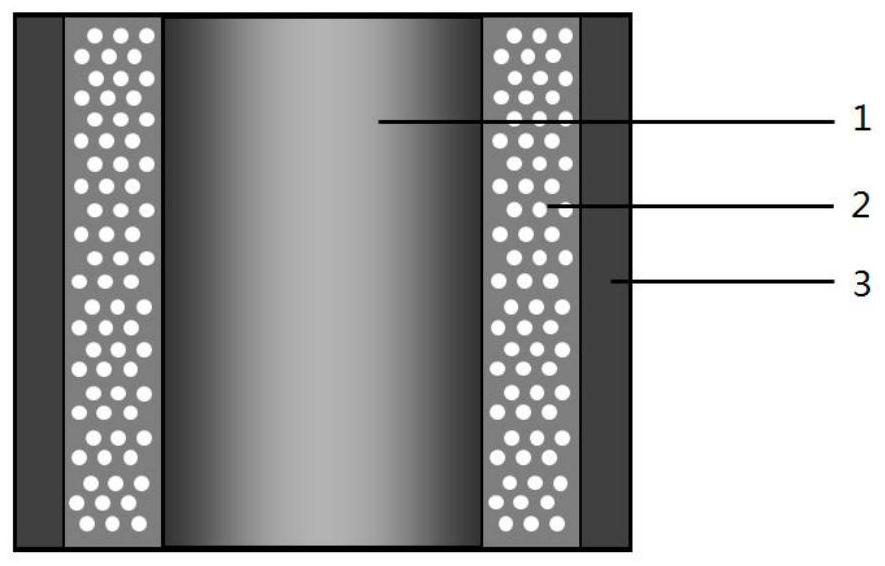

[0029] A fast neutron reactor high burnup metal fuel element with graphite foam as heat conduction medium, see Figure 1~2 shown, including:

[0030] The fuel core 1 and the cladding 3 provided on the side wall of the core 1 are filled with a porous heat-conducting medium 2 between the core 1 and the cladding 3 .

[0031] The fuel core 1 is a cylindrical fuel rod with a diameter of 4.8 mm and made of uranium-zirconium alloy;

[0032] The cladding 3 is made of ferritic-martensitic steel,

[0033] The wall thickness of the cladding 3 is 0.6mm,

[0034] The inner diameter of the cladding 3 is 6.0mm;

[0035] The porous heat-conducting medium 2 is graphite foam with a porosity of 70% (equivalent density 0.68g / cm 3 ), the average pore size is 70 μm, the thermal conductivity is 150 W / (m K), and the interior is filled with helium.

[0036] In the fuel core body provided in this embodiment, a part of space needs to be reserved above or below the fuel core body as an air cavity fo...

Embodiment 2

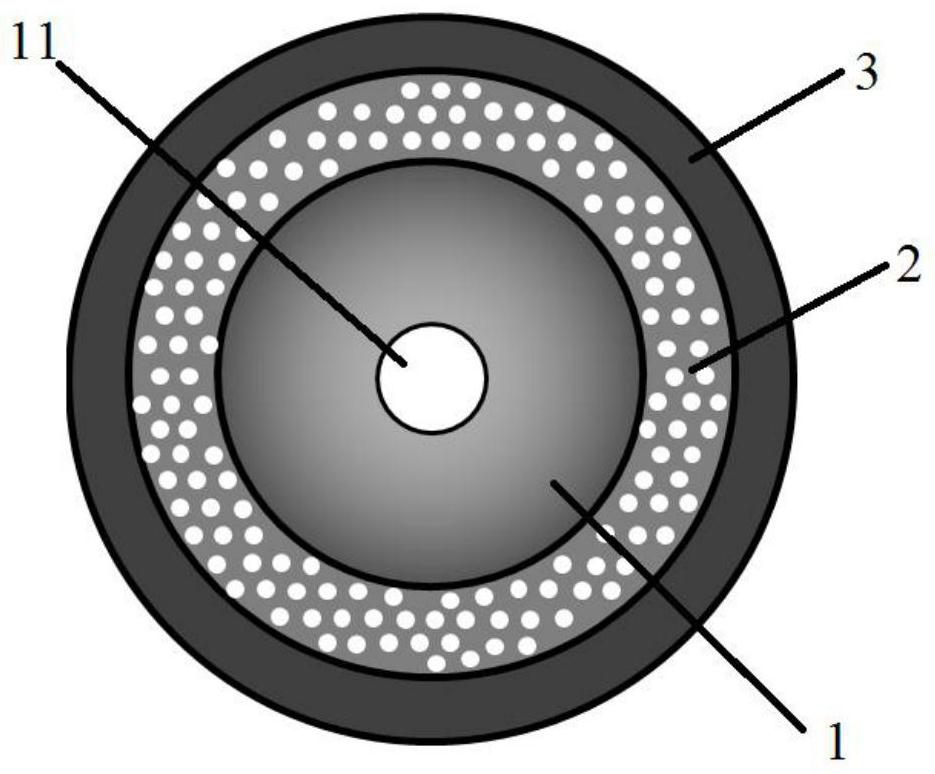

[0038] A fast neutron reactor high burnup metal fuel element with graphite foam as heat conduction medium, see image 3 shown, including:

[0039] The fuel core 1 and the cladding 3 provided on the side wall of the core 1 are filled with a porous heat-conducting medium 2 between the core 1 and the cladding 3 .

[0040] The core material is still uranium-zirconium alloy;

[0041] In order to reduce the temperature of the fuel core, a through hole 11 is opened in the center of the fuel core body 1. The radius of the through hole 11 is 1 / 3 of the outer radius of the core, and the through hole is filled with helium;

[0042] The cladding 3 is made of ferritic-martensitic steel,

[0043] The wall thickness of the cladding 3 is 0.6mm,

[0044] The inner diameter of the cladding 3 is 6.0mm;

[0045] The porous heat-conducting medium 2 is graphite foam with a porosity of 70% (equivalent density 0.68g / cm 3 ), the average pore size is 70 μm, the thermal conductivity is 150 W / (m K),...

Embodiment 3

[0048] A fast neutron reactor high burnup metal fuel element with graphite foam as heat conduction medium, see image 3 shown, including:

[0049] The fuel core 1 and the cladding 3 provided on the side wall of the core 1 are filled with a porous heat-conducting medium 2 between the core 1 and the cladding 3 .

[0050] The core material is still uranium-zirconium alloy;

[0051] In order to reduce the temperature of the fuel core, a through hole 11 is opened in the center of the fuel core body 1. The radius of the through hole 11 is 1 / 2 of the outer radius of the core, and the through hole is filled with helium;

[0052] The cladding 3 is made of ferritic-martensitic steel,

[0053] The wall thickness of the cladding 3 is 0.6mm,

[0054] The inner diameter of the cladding 3 is 6.0mm;

[0055] The porous heat-conducting medium 2 is graphite foam with a porosity of 70% (equivalent density 0.68g / cm 3), the average pore size is 70 μm, the thermal conductivity is 150 W / (m K), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com