Top emission quantum-dot light-emitting diode (QLED) field-effect transistor with micro-cavity structure and fabrication method of top emission QLED filed-effect transistor

A field-effect transistor and top-emission technology, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc. Monochromaticity and vertical luminous efficiency, achieving selectivity and structural improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

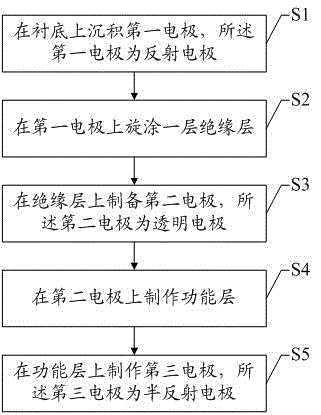

[0042] The present invention also provides a preferred embodiment of the method for preparing a top-emitting QLED field-effect transistor with a microcavity structure as described above, such as figure 2 As shown, it includes the steps:

[0043] S1. Depositing a first electrode on a substrate, where the first electrode is a reflective electrode;

[0044] S2. Spin coating an insulating layer on the first electrode;

[0045] S3. Prepare a second electrode on the insulating layer, and the second electrode is a transparent electrode;

[0046] S4, making a functional layer on the second electrode;

[0047] S5, making a third electrode on the functional layer, the third electrode is a semi-reflective electrode

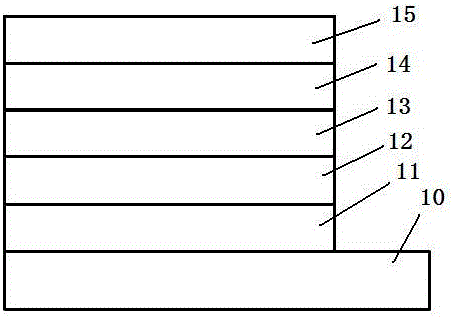

[0048] In the above step S1, the first electrode 11 is firstly deposited on the substrate 10 by evaporation as the FET gate, and at the same time as the FET anode or FET cathode, and the first electrode 11 is selected from a reflective material with better effect, such a...

Embodiment 1

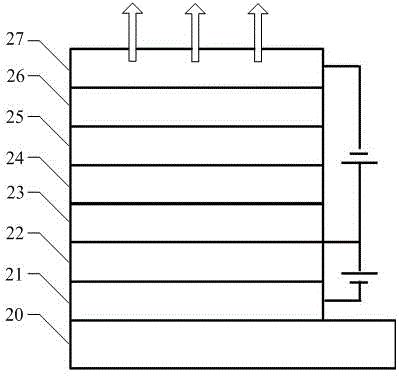

[0055] Such as image 3 As shown, the silicon-based substrate 20 can be cleaned by the standard Shiraki method, using organic solvent ambient ultrasonic, multi-step strong acid treatment, etc. to remove the surface oxide layer, organic impurities and metal element impurities. The first electrode 21 is deposited on the silicon-based substrate 20 by evaporation as the FET gate and as the FET cathode. The first electrode 21 is selected from a good light reflection material, such as Ag or Al, etc., and the thickness is preferably 1-100 nm. For example 20nm.

[0056] An insulating layer 22 is spin-coated on the first electrode 21, and the insulating layer 22 is also used as a device microcavity length adjustment layer, and the thickness of the insulating layer 22 depends on the light-emitting wavelength of the quantum dot light-emitting layer used. The insulating layer 22 is a transparent dielectric material. The insulating layer 22 can be made of PMMA or polyimide (PI). For exam...

Embodiment 2

[0063] Such as Figure 4 As shown, the silicon-based substrate 30 can be cleaned by the standard Shiraki method, using organic solvent ambient ultrasonic, multi-step strong acid treatment, etc. to remove the surface oxide layer, organic impurities and metal element impurities. The first electrode 31 is deposited on the silicon-based substrate 30 by evaporation as the gate of the FET and as the anode of the FET. The first electrode 31 is made of a good light-reflecting material, such as Ag or Al, with a thickness of preferably 1-100 nm.

[0064] An insulating layer 32 is spin-coated on the first electrode 31, and the insulating layer 32 also serves as a device microcavity length adjustment layer, and the thickness of the insulating layer 32 depends on the emission wavelength of the quantum dot light-emitting layer used. The insulating layer 32 is a transparent dielectric material. The insulating layer 32 can be made of PMMA or polyimide (PI). For example, when choosing PI mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com